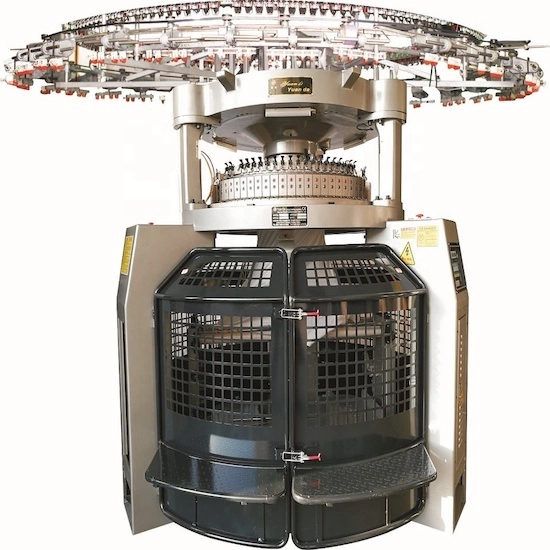

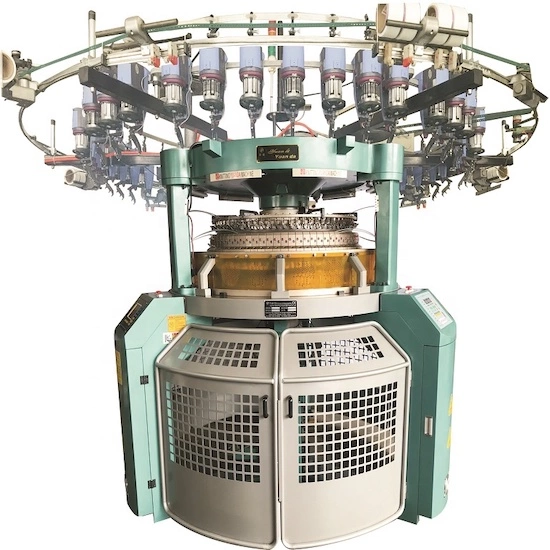

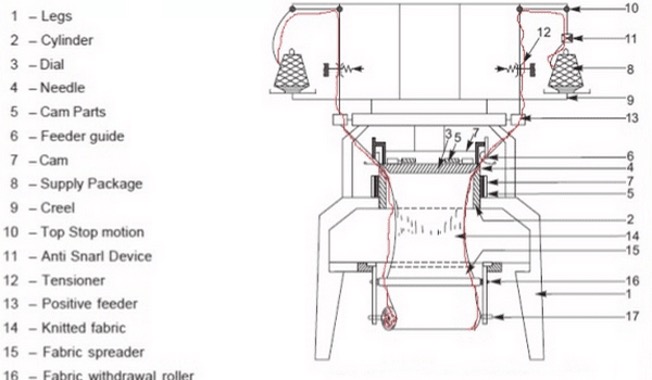

A double jersey circular knitting machine is a specialized textile production equipment used in the creation of knitted fabrics. This type of machine is designed with two needle beds which enables it to produce interlock, rib, and double jersey fabrics. With advanced technology and precision components, the double jersey circular knitting machine results in high-quality knitted fabrics in a variety of patterns and designs. It boasts of operational efficiency, versatility, and the ability to produce fabrics with varying degrees of stretch and compressibility depending on the customers' requirement. The machine is widely used in textile manufacturing for producing garments, home textiles, and other products. The double jersey circular knitting machine is a perfect choice for businesses looking to optimize their textile production and meet the ever-increasing demands of customers.

A double jersey knitting machine has two sets of needles setting on the dial and cylinder, which is different from a single jersey knitting machine. It is used to knit double jersey fabric. Stability and efficiency are guaranteed due to the special big tripod structure. The type of the cloth can be easily changed due to the overall adjustable yarn feeding ring and adjustable yarn feeding nozzle.

A double jersey knitting machine has two sets of needles setting on the dial and cylinder, which is different from a single jersey knitting machine. It is used to knit double jersey fabric. Stability and efficiency are guaranteed due to the special big tripod structure. The type of the cloth can be easily changed due to the overall adjustable yarn feeding ring and adjustable yarn feeding nozzle.

More information about the double jersey knitting machine

| Sizes | Gauges | No. of Feeders | Available Materials |

| 8-44 Inch | 6-40 Gauges | 16-88 or 106 Feeders | Interlock fabrics, elastic health cloth, twill, air layer, double mesh, superior men's or women's apparel, etc. |

Equipment

| Items | Component | Description/Brand | |||||

| 1 | Machine structure | China mainland | |||||

| 2 | Cylinder | Japanese Steel Metel S45CL | |||||

| 3 | Cam Material | Japanese Steel Metel Grade SKD11 | |||||

| 4 | Vertical Yarn Feeder | Taiwan | |||||

| 5 | Cam Set up S/J | 2 Knit + 1 Miss + 1 Tuck | |||||

| 6 | Cam Set Up D/J | 2 Knit + 1 Miss + 1 Tuck | |||||

| 7 | Needle | Groz-Becker, Germany | |||||

| 8 | Sinker | Kernliebers, Germany | |||||

| 9 | Positive Feeders | China mainland | |||||

| 10 | Teeth Belt for positive feeder | Japan | |||||

| 11 | Lycra Feeders | China mainland | |||||

| 12 | Teeth Belt for lycra feeder | Japan | |||||

| 13 | Lycra Bottom Stop Motion | China mainland | |||||

| 14 | Oil Lubricator | Taiwan | |||||

| 15 | Inverter | Taiwan | |||||

| 16 | Motor | Taiwan | |||||

| 17 | Control Panel | Taiwan | |||||

| 18 | Aluminium Top Yarn Creel | Taiwan | |||||

| 19 | Quality adjustment Pully | Taiwan | |||||

| 20 | Aluminum Side Tube Creel | Taiwan | |||||

| 21 | Open width fabric take down system (open width only) | Taiwan | |||||

| 23 | Mechanical Take up system (D/J use only) | Taiwan | |||||

| 24 | Plaiter(S/J use only) | Taiwan | |||||

| 25 | Fabric Spreader to Control Shrinkage | Taiwan | |||||

| 26 | Needle detector | Taiwan | |||||

Showing 1–12 of 42 results

Double jersey circular knitting machine

There are two sets of needles on a double jersey circular knitting machine; one is on the dial and the other is on the cylinder.

A double jersey machine is not equipped with sinkers.

The two sets of needles make the fabric to be produced twice as thick as the single jersey fabric, that is, the double jersey fabric.

The double jersey knitting machine is the most popular model for knitting various kinds of double jersey fabrics.

Request a quote

A double jersey machine is not equipped with sinkers.

The two sets of needles make the fabric to be produced twice as thick as the single jersey fabric, that is, the double jersey fabric.

The double jersey knitting machine is the most popular model for knitting various kinds of double jersey fabrics.

Features of double jersey circular knitting machines

Stable performance and interchangeability allow for easy conversion to rib knitting machines, which enables this machine to meet the never-ending demands of the knitting market.

The cams on the lower and upper dials of this machine feature a closed-track design with cams of knit, tuck, and miss.

The yarn feeder can be adjusted alone, and by installing additional Lycra attachments, elastic double jersey fiber can be knitted. The main components are designed by CAD system and processed by CNC to improve precision of equipment.

An automatic oil lubricator is adopted for lubricating the needles and cylinder, which prevent the needles from damaging easily.

The cams on the lower and upper dials of this machine feature a closed-track design with cams of knit, tuck, and miss.

The yarn feeder can be adjusted alone, and by installing additional Lycra attachments, elastic double jersey fiber can be knitted. The main components are designed by CAD system and processed by CNC to improve precision of equipment.

An automatic oil lubricator is adopted for lubricating the needles and cylinder, which prevent the needles from damaging easily.

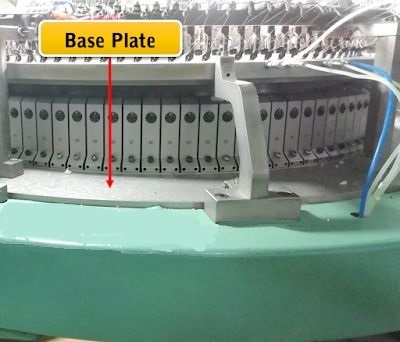

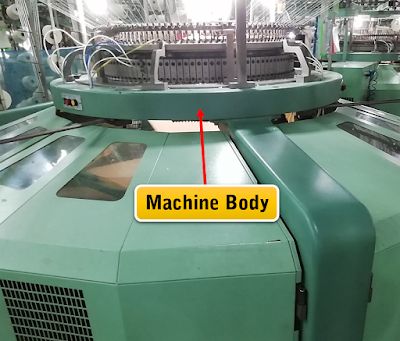

Parts of double jersey knitting machines

Circular knitting machines usually have parts such as cylinders, needles, feeders, cams, cam boxes, take up rollers, yarn tensioners, yarn guides, creels, base plates, auto Stoppers, VDQ pulleys, bodies, sinkers, etc.

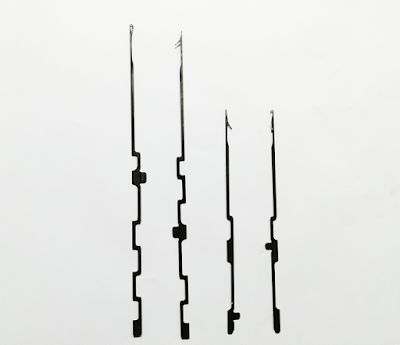

Needle

A needle can knit the fabric, which is one of the main parts of circular knitting machines. A needle includes a bearded needle, a latch needle and a compound needle and a latch needle is the most used.

Latch needles

A latch needle is a steel needle which has a butt at one end and a short hook closed by a latch at the other. A needle with high speeds can improve productivity.

A latch needle consists of a latch, a curved hook, a tumbler which swings on a rivet under the hook, stem and butt, which is applied to raschel and crochet machines. It can be referred to as an automatic needle sometimes because a presser is not required. The pressure of a completed loop on the latch closes the hook as the latch rises on the shaft.

A latch needle consists of a latch, a curved hook, a tumbler which swings on a rivet under the hook, stem and butt, which is applied to raschel and crochet machines. It can be referred to as an automatic needle sometimes because a presser is not required. The pressure of a completed loop on the latch closes the hook as the latch rises on the shaft.

Advantages of latch needles

Latch needles ensure that the fabric has good quality and productivity can be effectively improved by high speeds.

Latch needles save energy, thus reducing manufacturing costs.

Latch needles save energy, thus reducing manufacturing costs.

Features of latch needles

It has a wide application in the field of weft knitting.

It is more expensive compared with the bearded needle.

It is automatic or loop controlled.

It can work at any angle.

The depth of the needle determines the length of the loop.

The change in reciprocal height produces knitting, tuck, or missed stitch.

It is more expensive compared with the bearded needle.

It is automatic or loop controlled.

It can work at any angle.

The depth of the needle determines the length of the loop.

The change in reciprocal height produces knitting, tuck, or missed stitch.

Positive Feeder

A positive feeder is applied to stabilizing and adjusting the tension of the yarn feed. The self-cleaning tension ring is impressed on the wear-free yarn feed wheel and yarn infeed tensioner by the MPF L.

Advantages of positive feeders

A positive feeder has the advantages of easy use, easy maintenance, wear resistance and long service life. The self-cleaning vibrating yarn tensioner can avoid breaking down the circular knitting machine, thus improving productivity. The tension force is even because of the magnetic tension ring.

Features of positive feeders

Vibration tension devices

The vibrating tension disc rotates opposite the direction of the yarn feed, effectively preventing the dirt from accumulating on the tension disc, which is referred to as self-cleaning.

Enclosed storage feed rollers

The accumulation of residual yarn is avoided due to enclose and wear-resistant feed rollers and yarn storage while dealing with the multifilament yarn.

Built-in anti-residue device

When the multi-filament yarn is processed, capillary filaments will accumulate on the yarn storage roller, which will affect smooth yarn feeding. When weaving short-fiber yarn, users can output the yarn at a flat and shallow angle. When using multi-filament filaments, they can choose to output the yarn at a steeper angle to prevent accumulating the residual yarn.

Yarn feeding cantilevers

The yarn-feeding guide arm doesn’t need to be installed on the upper edge of the yarn-feeding machine due to this structure, and the replacement of the belt becomes faster and more convenient.

The vibrating tension disc rotates opposite the direction of the yarn feed, effectively preventing the dirt from accumulating on the tension disc, which is referred to as self-cleaning.

Enclosed storage feed rollers

The accumulation of residual yarn is avoided due to enclose and wear-resistant feed rollers and yarn storage while dealing with the multifilament yarn.

Built-in anti-residue device

When the multi-filament yarn is processed, capillary filaments will accumulate on the yarn storage roller, which will affect smooth yarn feeding. When weaving short-fiber yarn, users can output the yarn at a flat and shallow angle. When using multi-filament filaments, they can choose to output the yarn at a steeper angle to prevent accumulating the residual yarn.

Yarn feeding cantilevers

The yarn-feeding guide arm doesn’t need to be installed on the upper edge of the yarn-feeding machine due to this structure, and the replacement of the belt becomes faster and more convenient.

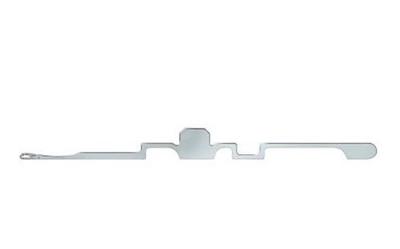

Lycra Feeder

The tension of the spandex feed is stabilized and adjusted by the lycra feeder.

Features of lycra feeder

A mechanical lever is used for the yarn breaking automatic stop device. According to the spandex’s tension, the counterbalance can be changed. The light path will be blocked and the yarn breaking stop signal triggered after the yarn breaks.

High-precision yarn feeding can be obtained because of all-metal shells and integrated wire feeding rollers, so that the quality of the fabric can be good.

The position of breakage of the yarn can be found easily due to the integrated LED indicator light, resulting in high work efficiency.

The breakage of the yarn can be analyzed by the optical technology and a reminder will be sent.

High-precision yarn feeding can be obtained because of all-metal shells and integrated wire feeding rollers, so that the quality of the fabric can be good.

The position of breakage of the yarn can be found easily due to the integrated LED indicator light, resulting in high work efficiency.

The breakage of the yarn can be analyzed by the optical technology and a reminder will be sent.

Cam

A cam is a crucial part of the knitting machine, which transmits the force to the needle bar and makes it move in a regular manner. In the fields of textiles, light industry, and mechanical transmission, cams are often applied. Different complicated regular movements can be achieved by using cams with different contours and grooves.

The features of cams

There are anti-oxidation layers, wear-resistant layers, waterproof layers and protective paint layers on the surface of the cam.

The cam is easy to be used and the labor intensity of the user is reduced.

The complex knitting motion is driven by a simple structure, resulting in a significant improvement in knitting.

The cam adopts a simple structure and is made from common materials, saving overall costs.

Yuanda is a professional manufacturer of circular knitting machines and their parts, we can not only supply circular knitting machines and their parts but also precise customization to help you further develop your business.

The cam is easy to be used and the labor intensity of the user is reduced.

The complex knitting motion is driven by a simple structure, resulting in a significant improvement in knitting.

The cam adopts a simple structure and is made from common materials, saving overall costs.

Yuanda is a professional manufacturer of circular knitting machines and their parts, we can not only supply circular knitting machines and their parts but also precise customization to help you further develop your business.

Cam box

A cam box has the function of holding the cam based on the design of the fabric.

Creel

Creel is used to put the yarn cone where the yarn is transported to the machine through the pipe.

Auto Stopper

If the knitting machine malfunctions, the automatic stopper will automatically stop the knitting machine.

VDQ pulley

VDQ is the variable dia of the quality pulley, which has control of the quality of the fabric and is essential for keeping appropriate stitch length.

The cloth rolling machine

Features of the cloth rolling machine

It has multi-step changing speeds and an intensive average of changing speed with no speed repetition. There is a large pack-up cloth extent, which is easy to use.

The wet lubricant was adopted for the machine's gear case, which is easy to maintain and not susceptible to wear.

The size and tightness of the cloth can be fixed by the machine, and the needle's service life can be longer.

By using this machine, the cloth shows no difference in starting and ending stripe distance and yard weight.

The cloth rolling machine can record with graduation while producing.

Adjustments can be made based on previous records.

It has multi-step changing speeds and an intensive average of changing speed with no speed repetition. There is a large pack-up cloth extent, which is easy to use.

The wet lubricant was adopted for the machine's gear case, which is easy to maintain and not susceptible to wear.

The size and tightness of the cloth can be fixed by the machine, and the needle's service life can be longer.

By using this machine, the cloth shows no difference in starting and ending stripe distance and yard weight.

The cloth rolling machine can record with graduation while producing.

Adjustments can be made based on previous records.

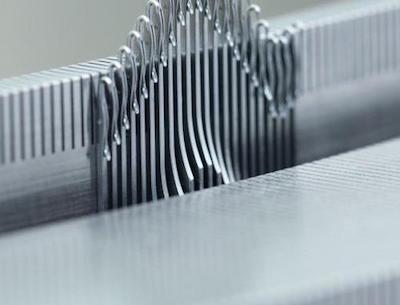

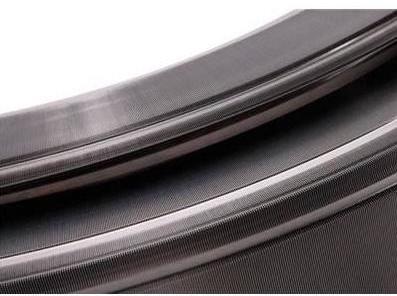

Cylinder

As the main component of a knitting machine, the adjustment of the cylinder is important. The cylinder is equipped with a needle, sinker, cam, and others. They have features of high accuracy, good wear resistance and long service life. The gauges are between 14 and 44, which are applied to single-jersey and double-jersey machines. More requirements are put forward for processing iron accessories. They need to be kept in the open air before processing. This will release the internal stress of the iron parts, thus reducing expansion caused by heat and contraction caused by cold and mechanical deformation of the iron parts. More importantly, accuracy and long service life will be improved.

The features of cylinders

Product with good quality is guaranteed by using steel-slice from Taiwan when the cylinder is running at high speed.

High-impact materials from Japan and Europe are used to ensure stabilization.

Special circulation heat treatment is adopted to ensure the balance and consistency of quenching rigidity of cylinders.

Increase turnout and reduce cotton wool cumulus and times of cleaning to match the dust hole treatment.

Vertical grinding machine is used for rubbing to make the cylinder’s plow groove smooth.

High-impact materials from Japan and Europe are used to ensure stabilization.

Special circulation heat treatment is adopted to ensure the balance and consistency of quenching rigidity of cylinders.

Increase turnout and reduce cotton wool cumulus and times of cleaning to match the dust hole treatment.

Vertical grinding machine is used for rubbing to make the cylinder’s plow groove smooth.

Fabric

Double jersey fabric

Double jersey fabrics are similar to single jersey fabrics, but they are knit by two sets of needles. The difference is that the two sides of a double jersey fabric are the same.

Request a quote

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links