How to Resolve Yarn Issues in Circular Knitting Machines

Dec 01, 2023

For knitwear manufacturers, operational hiccups with circular knitting machines and the yarn utilized can lead to subpar fabric quality, production setbacks, and increased expenses. This article delves into prevalent yarn issues and provides solutions.

Yarn Breakage Woes:

One of the primary concerns of circular knitting machines manufacturers encounter is yarn breakage. Factors such as excessive tension, machine rough edges, or mishandling during transportation can contribute to this issue. To mitigate yarn breakage, scrutinize the knitting machine's tension settings. High tension is a common culprit, and adjusting it to the appropriate level can thwart breakage. Regularly inspecting the machine for rough edges also plays a preventive role.

Combatting Yarn Snarling:

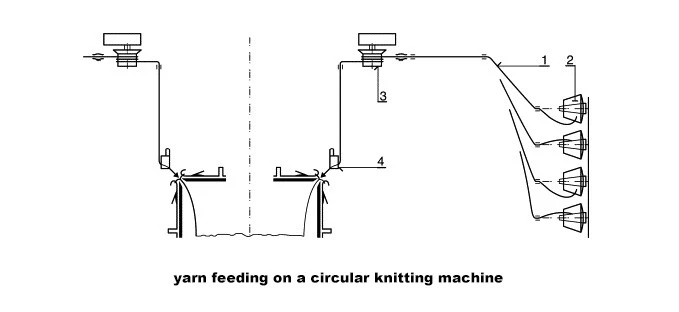

Yarn snarling, resulting from twists or tangles during knitting, poses another common challenge. This can lead to fabric defects and production delays. To circumvent snarling, ensure proper winding of yarn before its use in the machine. Employing correct yarn feeding techniques is crucial in averting snarling issues.

Addressing Yarn Quality Concerns:

Yarn quality directly impacts fabric excellence, making it imperative to use high-quality yarn tailored for the specific knitting machine. Each machine brand may work optimally with different yarn types, and selecting the wrong variant can spell trouble. Opting for specialized, high-quality yarn designed for your machine ensures consistent and efficient fabric production.

Preventing Yarn Storage Pitfalls:

Improper yarn storage can introduce complications in the production process. Yarns must be stored in a clean, dry environment to shield against environmental factors like moisture and UV light. Moisture-induced swelling in yarn can lead to machine jams and breakage. Furthermore, safeguarding yarn from UV light is crucial to prevent material weakening and breakdown.

Conclusion:

Maintaining circular knitting machine performance necessitates vigilance in addressing common yarn challenges. Employing high-quality yarn, coupled with correct feeding, storage, and machine maintenance practices, acts as a deterrent against issues like yarn breakage, snarling, fabric defects, and production delays. Business owners can significantly enhance product output quality and efficiency by attentively monitoring yarn quality and machine settings. This proactive approach not only prevents costly returns but also ensures a seamless production process with top-notch fabric outcomes.

Prochain: Guide to Selecting Circular Knitting Machine Needles

previous: How to Modify Patterns on a Double Jersey Computerized Jacquard Machine