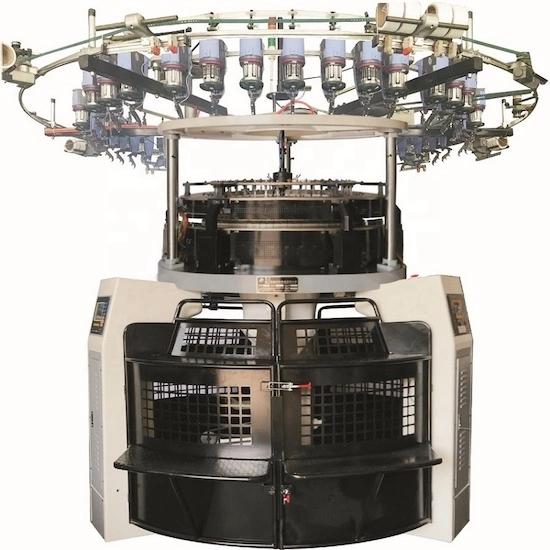

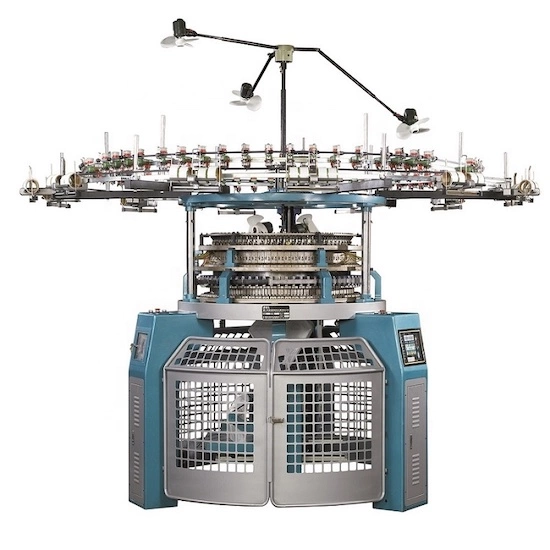

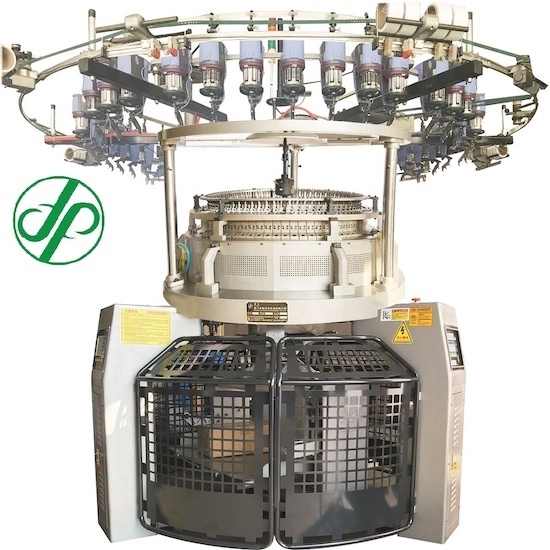

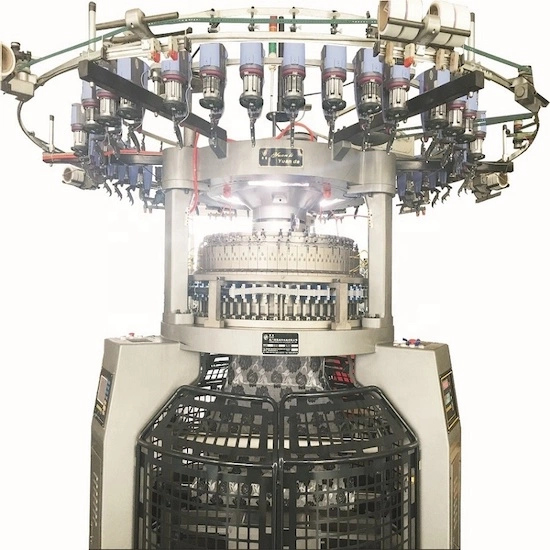

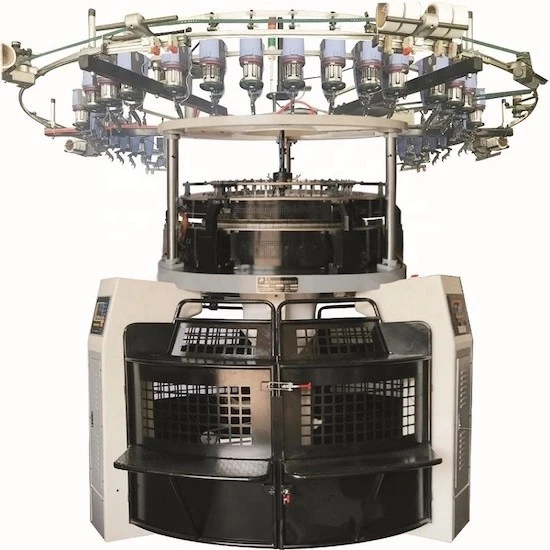

A jacquard circular knitting machine is a powerful piece of equipment for producing high-quality knit fabrics. It works by using a series of circular needles to create intricate designs and patterns in the fabric. This machine is known for its versatility, as it can produce both single and double jersey fabrics. Additionally, the jacquard feature allows for advanced pattern making, making it ideal for producing high-end clothing, home textiles, and other similar products. With its advanced technology and precision engineering, this circular knitting machine can handle a wide range of textiles and provides a cost-effective solution for producing high-quality knit fabrics.

A jacquard circular knitting machine is classified into a single jersey jacquard circular knitting machine and a double jersey jacquard knitting machine, which is fully electronic controlled. Abrasion and noise are reduced due to oil lubrication of top and bottm gears, improving the precision and service life. A jacquard circular knitting machine is equipped with cams of 2 tracks in dia and 4 tracks in cylinder. A double structure can be replaced by changing the arrangement of cams.

More information about the jacquard circular knitting machine

A jacquard circular knitting machine is classified into a single jersey jacquard circular knitting machine and a double jersey jacquard knitting machine, which is fully electronic controlled. Abrasion and noise are reduced due to oil lubrication of top and bottm gears, improving the precision and service life. A jacquard circular knitting machine is equipped with cams of 2 tracks in dia and 4 tracks in cylinder. A double structure can be replaced by changing the arrangement of cams.

More information about the jacquard circular knitting machine

| Sizes | Gauges | No. of Feeders | Available Yarn Materials |

| 30-38 Inch | 12G-28 Gauges | 54-84 Feeders | Cotton, silk, artificial wool, synthetic fiber, mesh or elastic cloth. |

Equipment

| Items | Component | Description/Brand | |||||

| 1 | Machine structure | China mainland | |||||

| 2 | Cylinder | Japanese Steel Metel S45CL | |||||

| 3 | Cam Material | Japanese Steel Metel Grade SKD11 | |||||

| 4 | Vertical Yarn Feeder | Taiwan | |||||

| 5 | Cam Set up S/J | 2 Knit + 1 Miss + 1 Tuck | |||||

| 6 | Cam Set Up D/J | 2 Knit + 1 Miss + 1 Tuck | |||||

| 7 | Needle | Groz-Becker, Germany | |||||

| 8 | Sinker | Kernliebers, Germany | |||||

| 9 | Positive Feeders | China mainland | |||||

| 10 | Teeth Belt for positive feeder | Japan | |||||

| 11 | Lycra Feeders | China mainland | |||||

| 12 | Teeth Belt for lycra feeder | Japan | |||||

| 13 | Lycra Bottom Stop Motion | China mainland | |||||

| 14 | Oil Lubricator | Taiwan | |||||

| 15 | Inverter | Taiwan | |||||

| 16 | Motor | Taiwan | |||||

| 17 | Control Panel | Taiwan | |||||

| 18 | Aluminium Top Yarn Creel | Taiwan | |||||

| 19 | Quality adjustment Pully | Taiwan | |||||

| 20 | Aluminum Side Tube Creel | Taiwan | |||||

| 21 | Open width fabric take down system (open width only) | Taiwan | |||||

| 23 | Mechanical Take up system (D/J use only) | Taiwan | |||||

| 24 | Plaiter(S/J use only) | Taiwan | |||||

| 25 | Fabric Spreader to Control Shrinkage | Taiwan | |||||

| 26 | Needle detector | Taiwan | |||||

Showing 1–12 of 30 results

Jacquard circular knitting machines

What's a single jersey jacquard circular knitting machine?

The needles are arranged in a circular bed and can be programmed to create different stitch types, such as tuck stitches, float stitches, and miss stitches. This single jersey jacquard knitting machine can produce high-quality fabrics quickly and efficiently. This makes it an ideal choice for manufacturers who need to produce large quantities of fabric in a short amount of time.

What's a double jersey jacquard circular knitting machine?

This machine has two needle beds, which allows for the creation of double-layered fabrics. The circular design of this knitting machine allows for continuous production of fabrics without any seams, making it ideal for creating garments such as sweaters, hats, and scarves. The double jersey feature creates a thicker and warmer fabric, making it perfect for winter wear.

Features of single jersey jacquard circular knitting machines

They can create complex patterns using a combination of different colored yarns. This is achieved through the use of a jacquard mechanism, which allows for precise control over each individual stitch. They also have high production speed. They are capable of producing large quantities of fabric in a short amount of time, making them ideal for mass production.

Features of double jersey jacquard circular knitting machines

They can create intricate patterns using multiple colors of yarn. This is achieved through the use of a jacquard mechanism that allows the machine to knit different colors in specific areas of the fabric. They are capable of producing large quantities of fabric quickly and with minimal waste. These machines can be used to produce fabrics including cotton, wool, silk, and synthetic fibers.

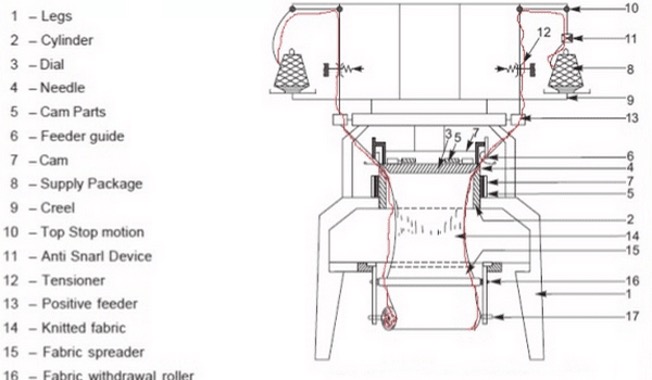

Parts of Jacquard knitting machines

Jacquard circular knitting machines consist of several parts that work together to create intricate patterns and designs on the fabric. Each part of a Jacquard circular knitting machine plays an essential role in producing high-quality fabrics with intricate designs and patterns. Some of the essential parts of a Jacquard circular knitting machine include the needle, needle bed, sinker, sinker ring, yarn feeder, yarn tensioners, yarn guides, cam, cam box, cylinders, feeders, take up rollers, creels and base plates.

Request a quote

Cylinder

A cylinder is a rotating drum with a series of needles arranged in a specific pattern that corresponds to the desired design. As the cylinder rotates, the needles pick up and drop stitches according to the programmed pattern, creating intricate designs and textures. The cylinder's size and needle arrangement determine the complexity of patterns that can be produced. A larger cylinder with more needles can create more intricate designs than a smaller one with fewer needles. Additionally, cylinders can be customized for specific fabric types and thicknesses.

Request a quote

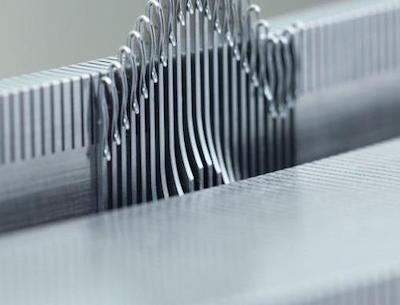

Needle

The needles for Jacquard circular knitting machines come in different sizes, depending on the desired pattern and fabric thickness. They are made from high-quality materials such as steel or titanium, which ensures their durability and longevity. One of the key benefits of using specialized needles for Jacquard circular knitting machines is their ability to produce highly detailed designs with precision and accuracy. This makes them ideal for creating high-quality fabrics that require intricate patterns, such as those used in fashion design or home decor.

Request a quote

Latch needles

Latch needles are designed to create intricate and complex patterns by selectively picking up and dropping yarns during the knitting process. The latch mechanism on these needles allows them to hold onto the yarn while it is being pulled through the fabric, ensuring that each stitch is uniform in size and shape. One of the key advantages of latch needles is their ability to produce fabrics with a wide range of textures and patterns. This makes them ideal for producing everything from simple knitwear to more complex garments such as sweaters, dresses, and even home furnishings.

Request a quote

Feeder

Feeders for Jacquard circular knitting machines come in different types, including positive feeders, negative feeders, and combination feeders. Feeders for Jacquard circular knitting machines also come with different features such as automatic thread trimming, electronic control systems, and multiple feeding channels. These features enhance productivity by reducing downtime caused by manual interventions.

Request a quote

Positive feeders

Positive feeders are commonly used in Jacquard circular knitting machines because they ensure consistent yarn feeding and reduce the risk of yarn breakage.

Request a quote

Cam

The cam for Jacquard circular knitting machines has played a significant role in advancing textile manufacturing technology. It has allowed designers to create more complex and intricate patterns on fabrics, making it possible to produce high-quality garments at an affordable price. The cam system consists of a series of rotating discs with various indentations or protrusions that control the movement of the needles. By adjusting the position and shape of these cams, different patterns can be created on the fabric. This technology has revolutionized the textile industry by allowing for mass production of intricate designs at a faster rate than traditional hand-knitting methods.

Request a quote

Cam box

A cam box is responsible for controlling the movement of needles and yarn during the knitting process. The cam box consists of a series of cams that are arranged in a specific pattern to create different designs and patterns on the fabric. The design of the cam box varies depending on the type of fabric being produced. For example, if the fabric requires a simple design, then a basic cam box will suffice. However, if intricate designs are needed, then a more complex cam box with multiple cams will be required.

Request a quote

Yarn tensioner

A yarn tensioner for Jacquard circular knitting machines is an essential tool that helps to maintain the correct tension of the yarn in the knitting process. The tensioner is designed to ensure that the yarn is fed into the machine at a consistent rate, which results in high-quality knitted fabrics.

The yarn tensioner works by regulating the amount of tension applied to the yarn as it passes through the machine. This ensures that there are no loose or tight stitches, which can affect the overall quality of the fabric. The device also helps to reduce breakages and snags in the yarn, which can cause interruptions in production.

Request a quote

The yarn tensioner works by regulating the amount of tension applied to the yarn as it passes through the machine. This ensures that there are no loose or tight stitches, which can affect the overall quality of the fabric. The device also helps to reduce breakages and snags in the yarn, which can cause interruptions in production.

Yarn guide

A yarn guide is responsible for guiding the yarn through the machine, ensuring that it is fed properly and consistently to produce high-quality knitted fabrics. One important consideration when using a yarn guide on a Jacquard circular knitting machine is tension. Proper tension ensures that the yarn feeds smoothly through the machine without becoming tangled or breaking. This can be achieved by adjusting the position of the hooks and guides as well as by adjusting other settings on the machine.

Request a quote

Creel

The creel typically consists of a metal frame with multiple arms extending from it, each holding a cone of yarn. The arms are adjustable, allowing for customization based on the specific needs of each knitting project. Without a properly functioning creel, the knitting process can be disrupted and result in uneven or incomplete patterns. Therefore, investing in a high-quality creel is crucial for achieving consistent and professional results when using a Jacquard circular knitting machine.

Request a quote

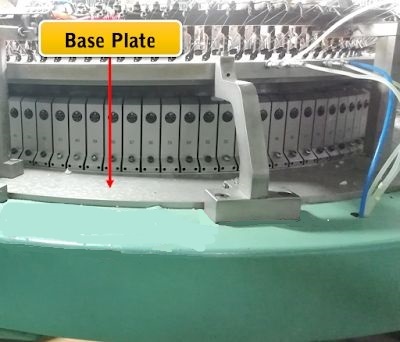

Base plate

The base plate is essentially a flat, circular metal plate that serves as the foundation for the entire machine. It provides stability and support to all the other components of the machine, including the needles, sinkers, and cams. The base plate also houses several important mechanisms that are responsible for controlling the movement of these components. These mechanisms include various types of sensors, motors, and controllers that work together to ensure precise and accurate knitting patterns.

Request a quote

Auto Stopper

The Auto Stopper is a device that has been designed to automatically stop the knitting machine when there is a yarn breakage or any other technical issue, which ensures that the quality of the fabric produced is not compromised and also saves time and resources.

Request a quote

VDQ pulley

The VDQ Pulley is responsible for controlling the movement of needles and yarns, allowing them to create various designs on the fabric. It is made from high-quality materials that ensure its durability and long service life. It has a unique design that allows it to operate smoothly and efficiently, reducing downtime and increasing productivity. Its precision engineering ensures that it can handle high speeds without compromising accuracy or quality. It can be adjusted to accommodate different types of yarns, fabrics, and patterns, making it suitable for a wide range of applications.

Request a quote

Sinker

A sinker is a thin, metal plate with a curved shape that helps to guide the yarn as it moves through the machine. The sinker works in conjunction with other components such as needles and cams to create intricate patterns and designs on the fabric. The sinker plays a vital role in ensuring that the yarn is held securely in place during the knitting process. It also helps to regulate the tension of the yarn, which is critical for producing high-quality fabrics.

Request a quote

The cloth rolling machine

The cloth rolling machine is designed to roll up the finished fabric from the knitting machine onto a roller, making it easier to transport and store. It saves time and effort as it can roll up large quantities of fabric quickly and efficiently and it ensures that the fabric is rolled evenly and tightly, preventing any wrinkles or creases from forming.

Request a quote

Fabrics

Jacquard knit fabrics are single jersey fabrics and double jersey fabrics made by circular jacquard knitting machines using a Jacquard mechanism. A needle is selected by the computer for the cylinder to knit jacquard fabrics with various patterns. Fabrics knit by Jacquard circular knitting machines are known for their durability, elasticity, and breathability. They are commonly used in sportswear, activewear, and other high-performance garments due to their ability to wick away moisture and regulate body temperature.

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links