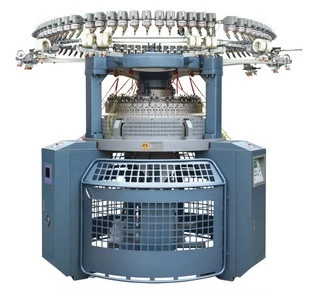

Optimizing Double Jersey Circular Knitting Machine Precision

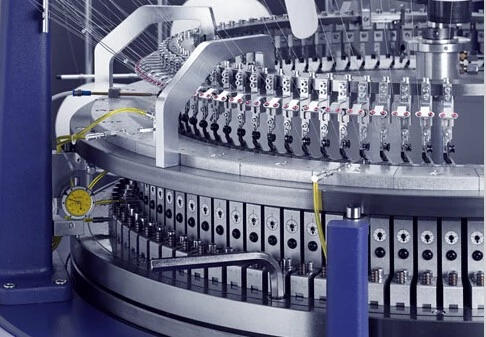

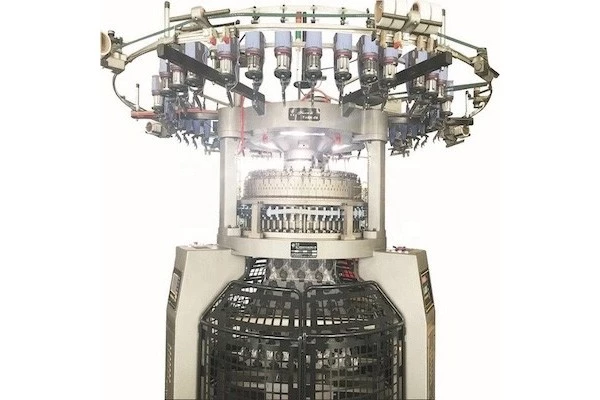

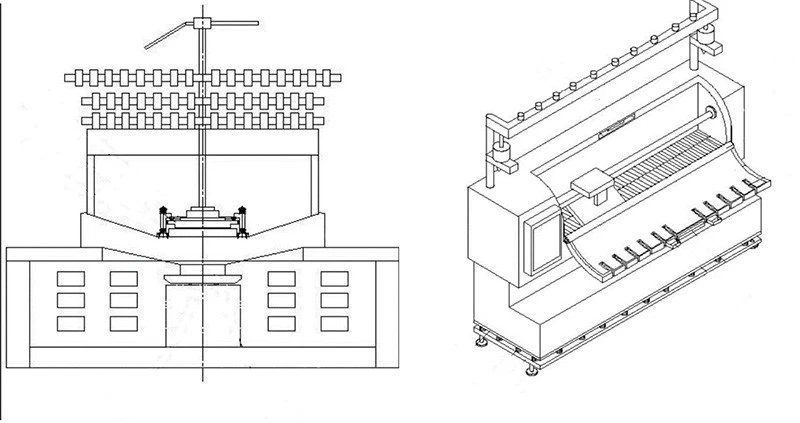

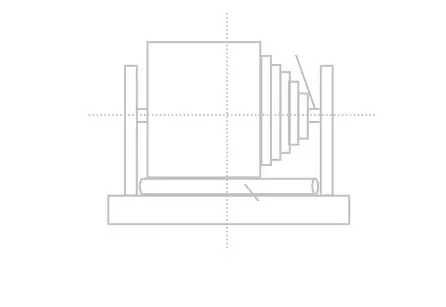

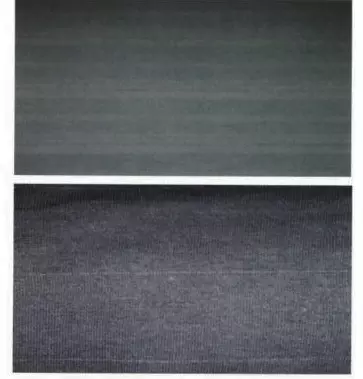

Double jersey circular knitting machines play a crucial role in textile manufacturing. However, maintaining precise circular degree and flatness is essential for optimal performance. This guide addresses common issues in double jersey circular knitting machines, such as chain wheel abrasion and flaws on the cylinder, providing methods for inspection and solutions. Chain Wheel Abrasion Chain wheel abrasion can lead to loosening or wearing issues. To inspect: 1. Stop the machine and place a dial...