What Is a Jacquard Knitting Machine?

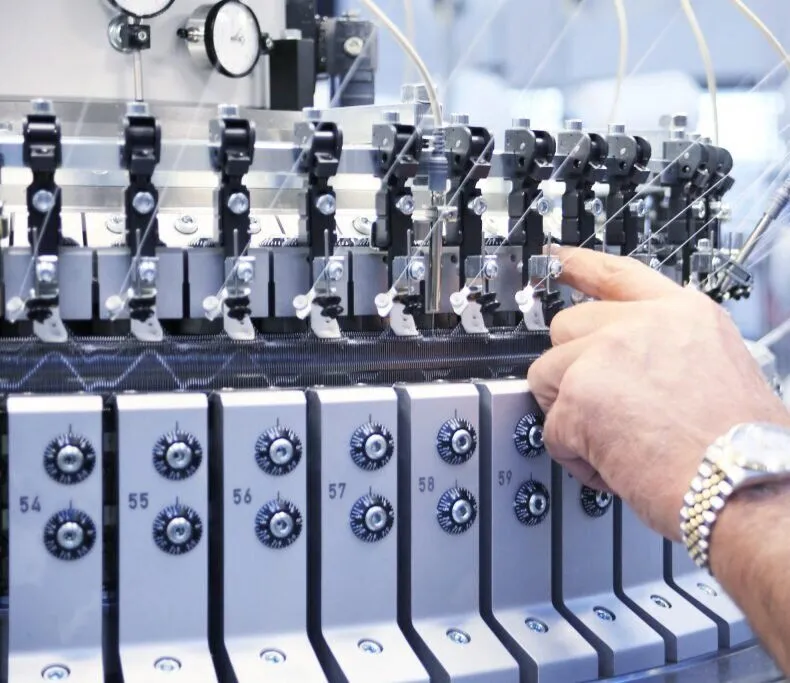

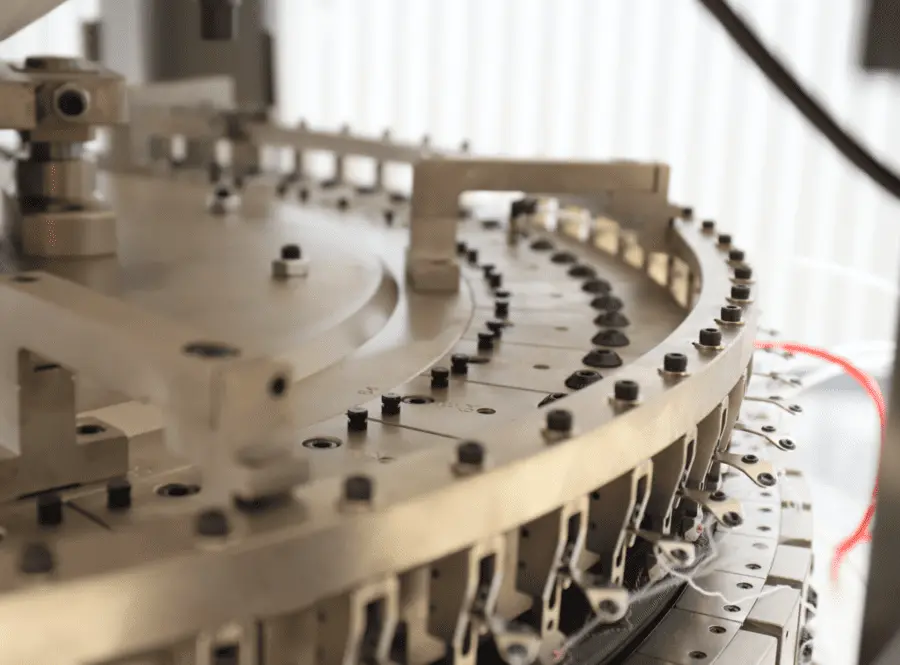

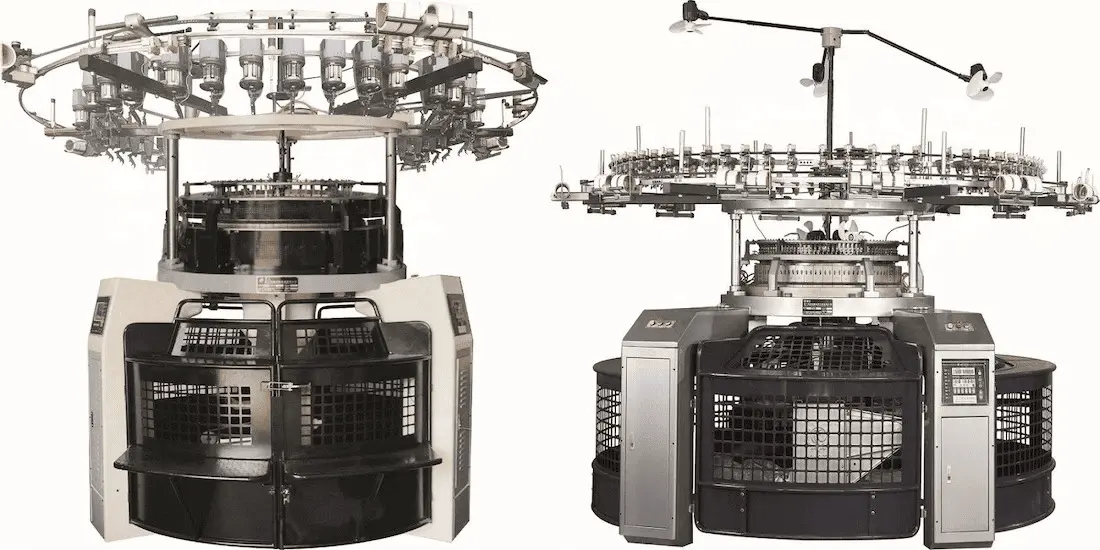

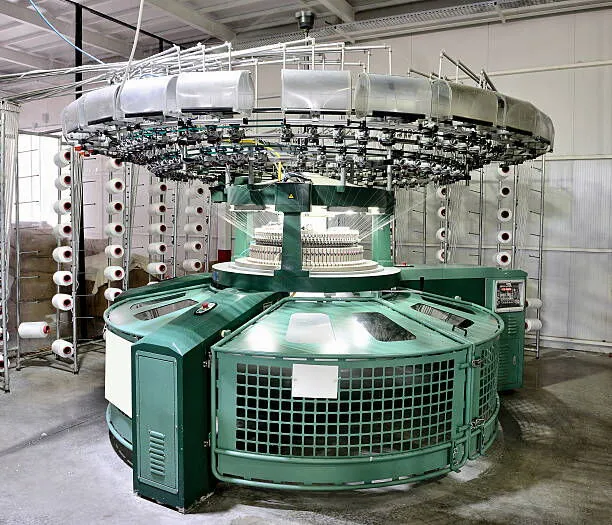

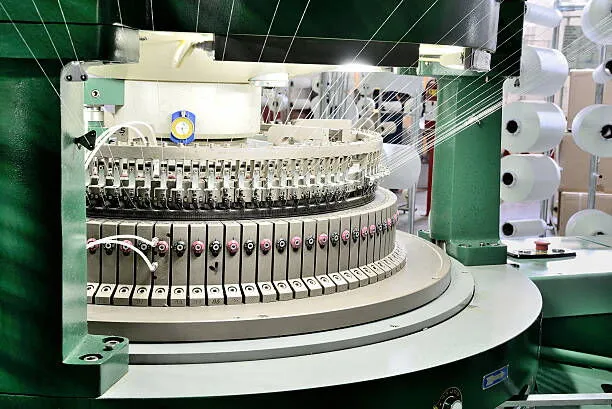

Jacquard knitting machines are an innovation in the textile industry, offering advanced capabilities for creating intricate patterns and seamless fabrics. These machines are revolutionizing knitwear manufacturing with their precision, efficiency, and adaptability, making them indispensable for both large-scale production and intricate design work. Let’s explore the features, benefits, and working mechanisms of jacquard knitting machines and understand why they are such a valuable asset in...