The Role of Clockwise and Counterclockwise Rotation in Circular Knitting Machines

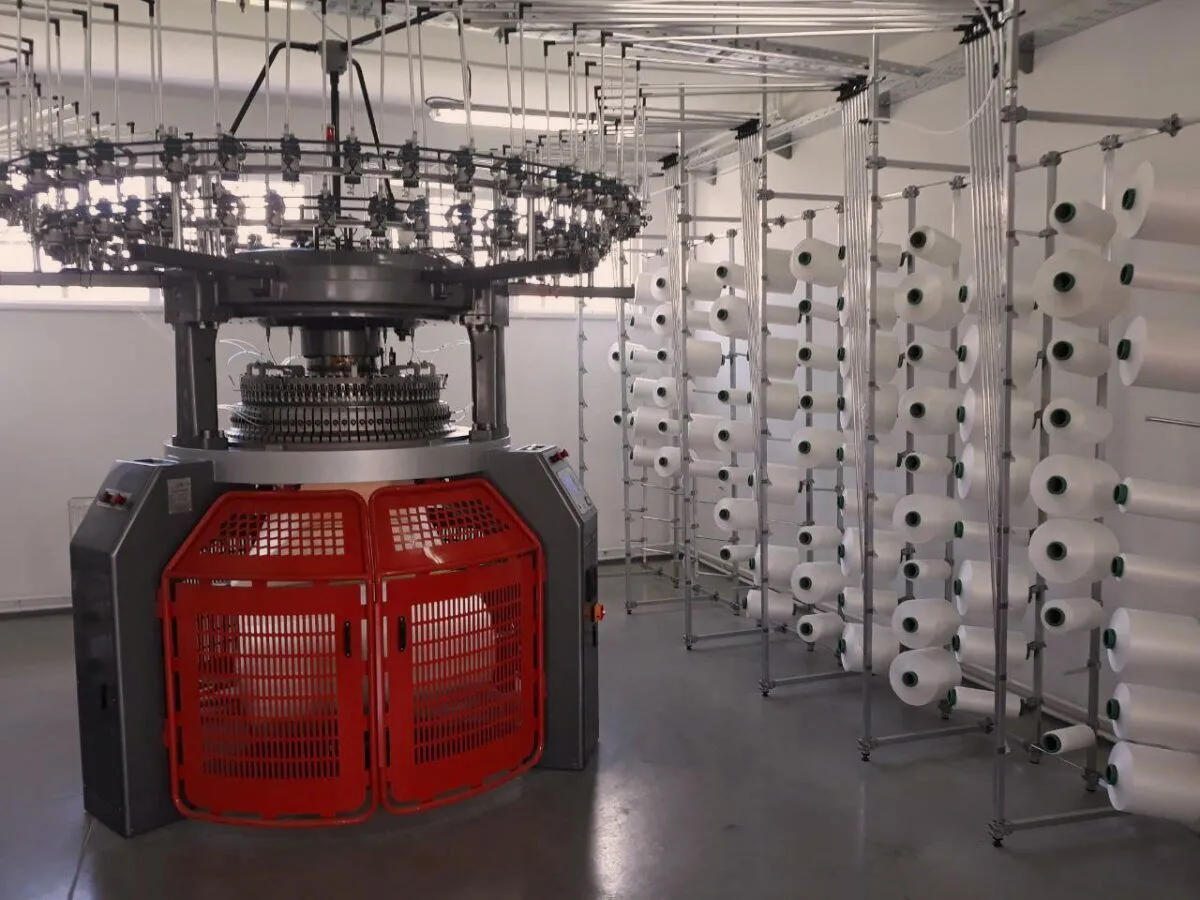

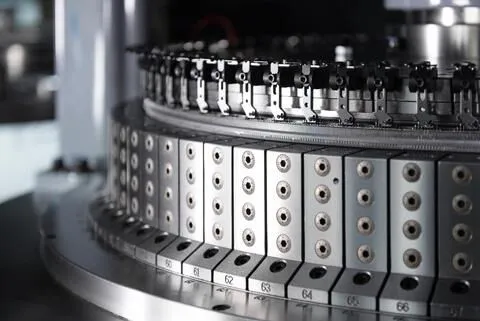

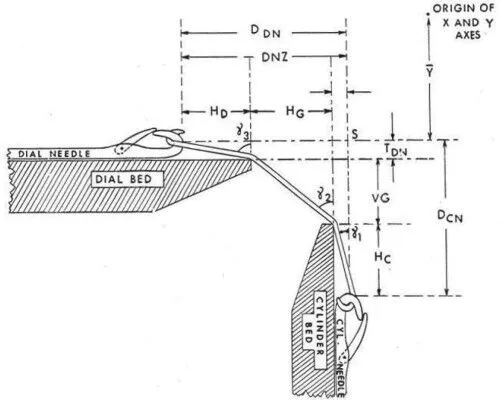

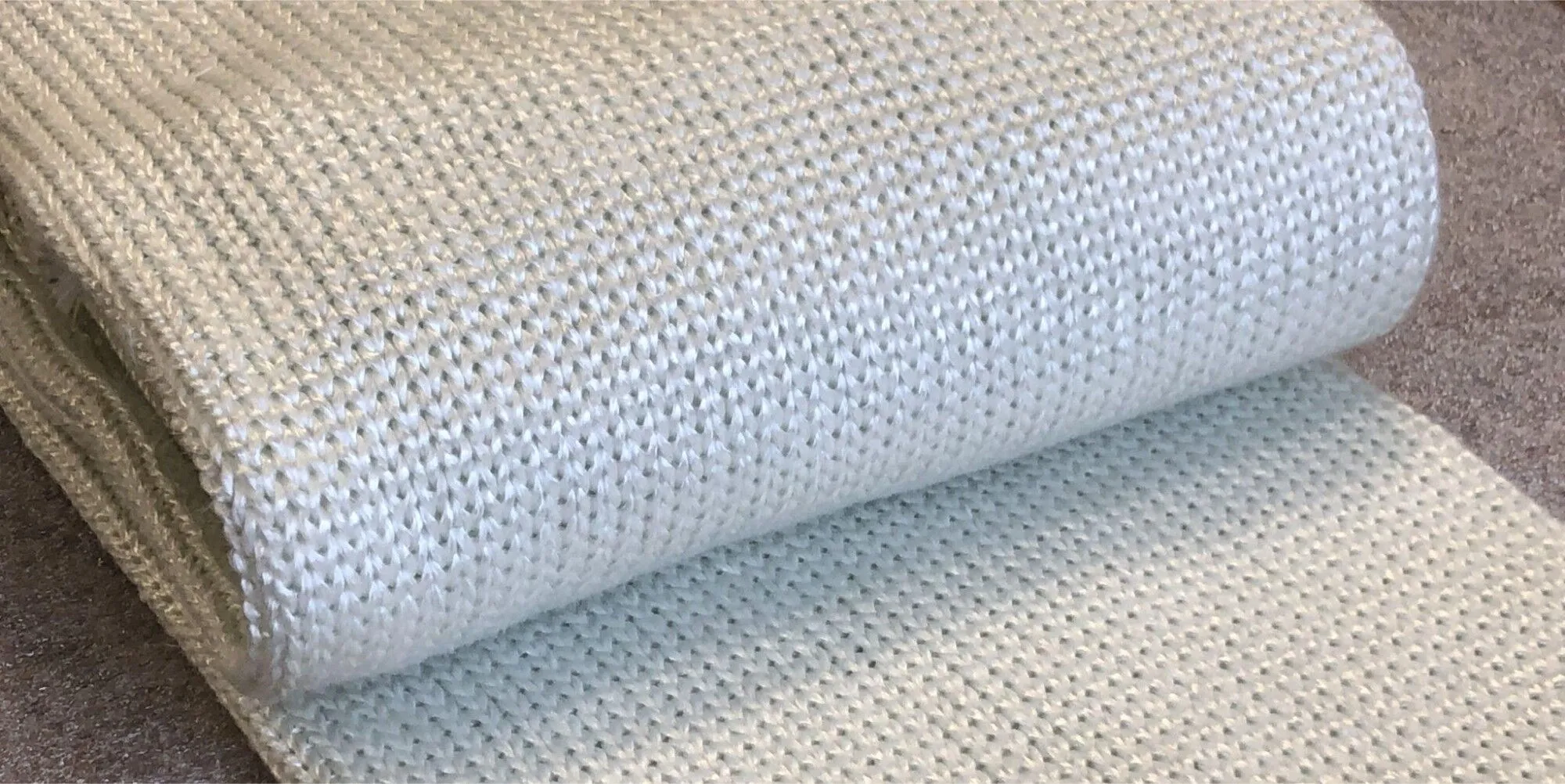

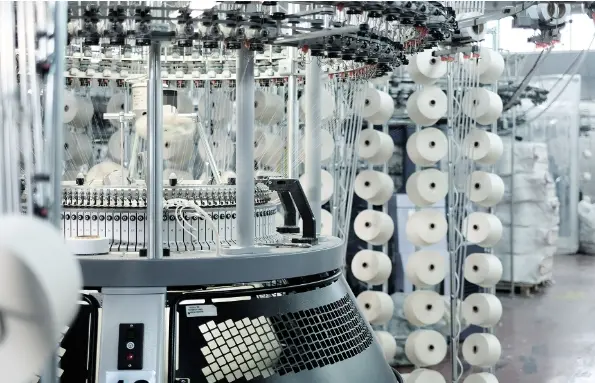

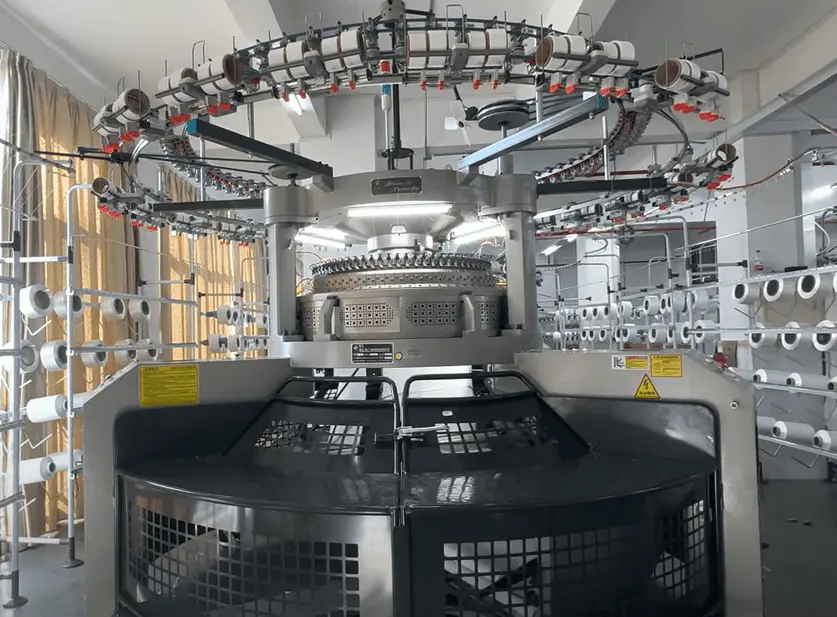

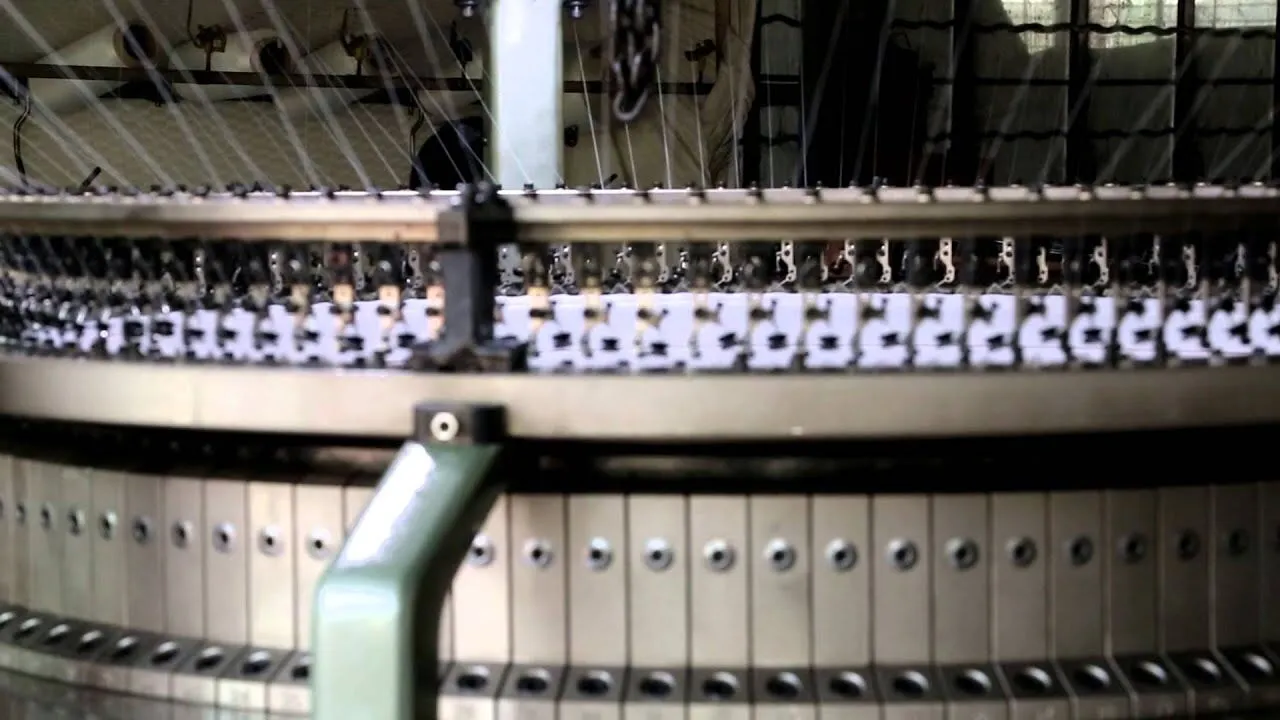

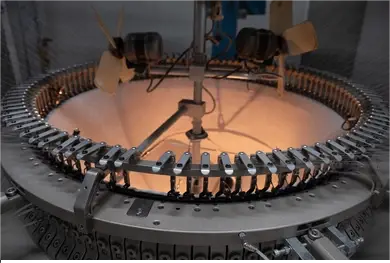

Circular knitting machine is an important equipment in the textile industry, which plays a very important role in the production of various knitted fabrics and clothing. These machines work in a circular motion to create seamless fabric tubes, making the production process efficient and versatile. However, to fully utilize the potential of circular knitting machines in actual production, it is important to understand the concept of clockwise and counter-clockwise rotation. These two terms are not...