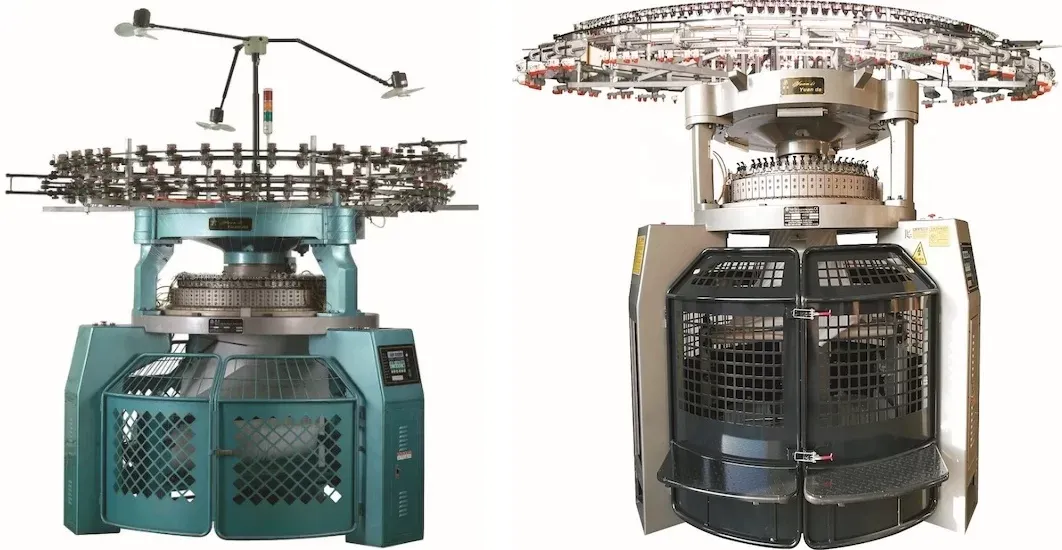

A Comprehensive Guide to Double Jersey Circular Knitting Machines

Nov 29, 2024

A Double Jersey Circular Knitting Machine is a highly specialized piece of textile machinery designed for producing high-quality double-knit fabrics. These machines operate in a single rotational direction, with knitting systems distributed along the machine’s circular bed. The number of systems can be increased by enlarging the machine's diameter, which directly enhances productivity by increasing the number of courses inserted with each revolution.

For instance, simpler fabric constructions, such as jersey stitches, can feature up to 180 systems, allowing for exceptional efficiency and output. This capability makes Double Jersey Circular Knitting Machines indispensable in modern textile production, where speed, quality, and versatility are critical.

The knitting process on a Double Jersey Circular Knitting Machine begins with yarn fed from spools arranged on a holder. This holder can be a creel, positioned beside the machine, or a rack, placed above it. From there, the yarn is guided into the knitting zone via a thread guide.

The thread guide, which consists of a small plate equipped with a steel eyelet, ensures the yarn remains steady and directed correctly during the knitting process. For producing intricate patterns, such as intarsia or specialty effects, the machine can be equipped with advanced thread guides specifically designed for such applications.

One key feature of modern Double Jersey Circular Knitting Machines is the integration of high-cost-effective positive feeders, such as the NEO-KNIT feeder, which incorporates several advanced technologies:

Aluminum Alloy Chassis: Provides robustness, ensuring resistance to both distortion and corrosion, which is essential for prolonged use.

LED Indicators: Long-lasting and clearly visible from any operator position, these LEDs enhance operational efficiency.

Electrostatic Prevention Design: Reduces dust accumulation, ensuring smoother yarn flow and improved overall machine performance.

These innovative features ensure higher productivity, consistent fabric quality, and ease of maintenance, making Double Jersey Circular Knitting Machines a staple in modern textile manufacturing.

Double Jersey Circular Knitting Machines produce fabrics known for their durability, stretch, and versatility. These fabrics are widely used in various applications, including:

Vests: Lightweight and breathable, perfect for summer wear or as inner layers.

T-Shirts: A popular choice for casual wear, offering softness and comfort.

Sportswear: The stretch and durability of double jersey fabrics make them ideal for athletic and activewear.

Fitness Suits: Designed for flexibility and comfort during workouts.

Swimwear: Double jersey fabrics resist wear and maintain elasticity, making them suitable for garments exposed to water and chlorine.

These applications highlight the versatility and utility of double-knit fabrics in meeting diverse consumer and industry needs.

One common question in the textile industry is the difference between interlock fabrics and double jersey fabrics. While both are double-knit fabrics, they differ in weight, texture, and applications.

Interlock Fabrics: Heavier, thicker, and warmer, making them suitable for winter clothing. Their dense structure also adds durability.

Double Jersey Fabrics: Lighter and softer, often chosen for garments like T-shirts and vests that prioritize comfort and breathability.

Interlock Fabrics: These fabrics are tightly knit, giving them a smoother, more uniform appearance on both sides. They feel sturdy and robust to the touch.

Double Jersey Fabrics: While still durable, they have a more flexible and softer texture, with a flatter appearance ideal for casual or summer wear.

In recent years, technological advancements have transformed Double Jersey Circular Knitting Machines into highly efficient and adaptable systems. Some of the key innovations include:

Modern machines, like those equipped with NEO-KNIT feeders, offer unparalleled precision in yarn feeding. These feeders ensure consistent tension, minimizing defects in the final fabric and enhancing productivity.

Features like aluminum alloy chassis and electrostatic prevention designs reduce wear and tear while ensuring that dust accumulation—a common issue in knitting operations—is minimized. This results in lower maintenance requirements and extended machine lifespans.

With specialized thread guides and advanced programming capabilities, these machines can handle a variety of yarns and create intricate patterns, opening up possibilities for innovative fabric designs.

The adoption of Double Jersey Circular Knitting Machines offers numerous advantages to textile manufacturers, including:

By embracing technological advancements, such as high-performance feeders and electrostatic prevention designs, these machines continue to evolve, ensuring their relevance in an ever-changing industry. Whether for large-scale production or intricate fabric designs, Double Jersey Circular Knitting Machines remain a reliable and valuable investment for textile manufacturers worldwide.

Next: How Does a Rib Circular Knitting Machine Work?

Previous: What Is a Jacquard Knitting Machine?

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.