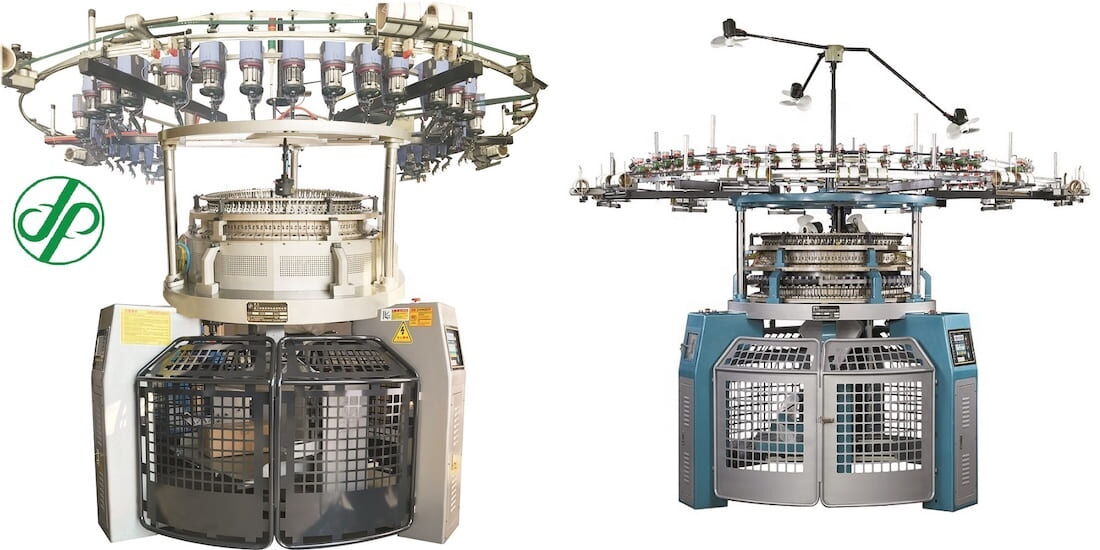

Advancing Textile Production with the Jacquard Circular Knitting Machine

Dec 08, 2024

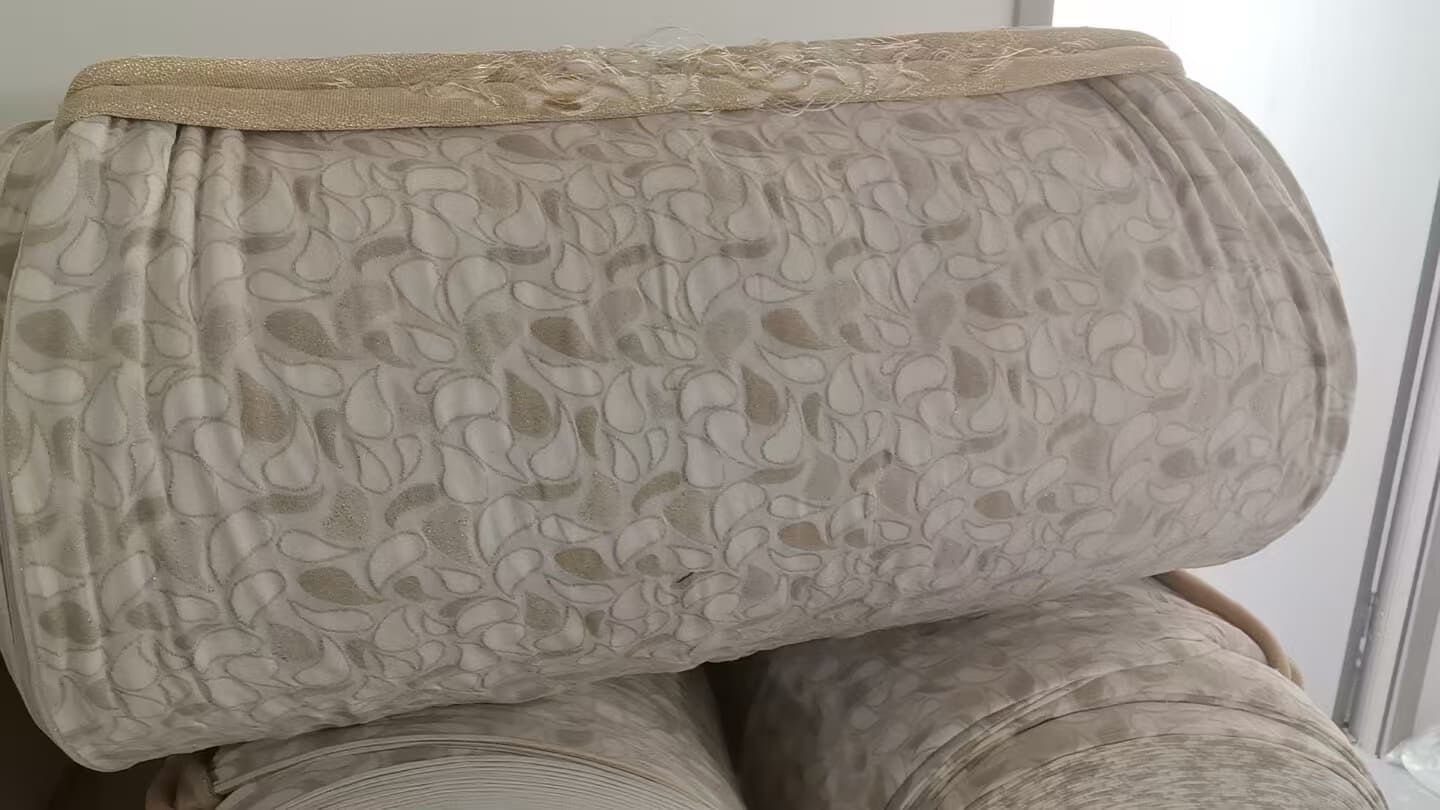

The Jacquard Circular Knitting Machine represents a significant leap forward in textile manufacturing, offering a perfect fusion of advanced technology and versatile fabric production. Unlike traditional jacquard machines, which are limited by mechanical selectors and processes, this innovative machine integrates state-of-the-art computerized selectors with a two-way technique of knit, tuck, and miss. This allows for the creation of highly intricate and varied fabric patterns without any limitations, ensuring designers have the freedom to experiment with complex designs.

At the core of this machine's functionality is its computerized pattern preparation system, which facilitates the conversion of any detailed fabric design into a specialized control command. This command instructs the computerized selectors to accurately produce the desired jacquard pattern. The advanced system streamlines the process of pattern changes, allowing manufacturers to save significant time and effort when switching from one design to another.

The integration of computerized selectors into the machine ensures a high level of precision and flexibility, enabling the production of intricate and detailed patterns that were once challenging or time-consuming to achieve using traditional jacquard techniques. The ability to adjust and fine-tune patterns on the fly makes this machine ideal for modern textile manufacturers, who need to stay competitive in a fast-paced, ever-evolving market.

One of the standout features of the Jacquard Circular Knitting Machine is its user-friendly interface. The machine incorporates a touch LCD display screen, which simplifies the operation process and enhances overall user experience. The intuitive touch-screen interface not only makes it easier to control the machine but also minimizes the need for complex physical controls, reducing operator fatigue and improving efficiency.

Additionally, the design of the LCD interface helps to save valuable space on the production floor, contributing to a cleaner, more organized workspace. This sleek, modern design is particularly beneficial for companies looking to optimize their facility layout and streamline their operations.

Unlike many traditional jacquard machines, the Jacquard Circular Knitting Machine doesn’t require specialized, proprietary software for pattern creation. Instead, the system allows manufacturers to use commonly available graphic software programs to scan and input patterns into the machine. Whether it’s a simple cloth cover design or a more complex intricate pattern, the machine’s flexibility ensures that any design can be imported and processed with ease.

Using WAC Designer software, patterns can be easily converted into needle selecting programs. Once these programs are created, they can be saved onto a USB drive and directly uploaded to the machine for production. This efficient method eliminates the need for complicated and costly proprietary software, making the machine a more cost-effective solution for textile manufacturers.

This ease of input and pattern management is a game-changer for fabric designers and manufacturers. It allows them to quickly test and implement new designs, providing them with the agility needed to respond to market demands or customer preferences with minimal delay.

The electronic control system integrated into the Jacquard Circular Knitting Machine is powered by the latest micro-processing technology, which ensures the utmost precision and flexibility during production. This advanced system governs the machine’s operation, ensuring accurate needle selection, optimal pattern execution, and consistent fabric quality.

The combination of the computerized selectors and the electronic control system provides a level of versatility that is unmatched by traditional mechanical systems. This setup allows for a broader range of fabric structures, patterns, and textures to be produced on a single machine. As a result, manufacturers can experiment with more complex designs and textures, expanding their product offerings and catering to a wider range of customer needs.

The integration of computerized control not only enhances the precision of the Jacquard Circular Knitting Machine but also significantly improves production efficiency. Pattern changes, which traditionally involved manual adjustments and downtime, are now achieved with minimal interruption. The ability to quickly switch between different designs without requiring significant machine reconfiguration allows manufacturers to reduce production lead times and increase throughput.

This efficiency extends beyond pattern changes. The simplified operation, facilitated by the LCD touchscreen and user-friendly programming system, ensures that operators can quickly and accurately set up the machine for new runs. This results in less downtime for setup and maintenance, translating into increased productivity and profitability for manufacturers.

In conclusion, the Jacquard Circular Knitting Machine is a transformative solution for the modern textile industry. With its ability to seamlessly integrate advanced computerized selectors, user-friendly interface, and flexible design input methods, the machine offers a level of control, precision, and versatility that was previously unattainable in traditional jacquard knitting machines.

By utilizing common graphic software and eliminating the need for expensive proprietary systems, this machine makes complex pattern production more accessible and cost-effective. Its efficient, time-saving features enable manufacturers to stay competitive in an industry where speed, quality, and innovation are key.

As textile manufacturers continue to seek ways to enhance their production capabilities, the Jacquard Circular Knitting Machine stands out as a cutting-edge solution that will undoubtedly shape the future of textile manufacturing. Whether producing intricate fabrics for fashion, home textiles, or industrial applications, this machine offers the technology and flexibility needed to meet the demands of an ever-evolving market.

Next: Operation of Circular Knitting Machines: Comprehensive Guide

Previous: Exploring the Double Jersey Transfer Jacquard Knitting Machine

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.