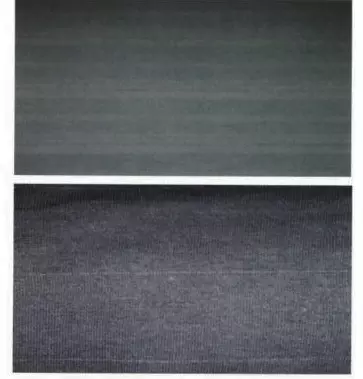

Analysis and Prevention of Horizontal Bars in Knitted Fabrics

Dec 07, 2023

In the realm of textile manufacturing, the occurrence of irregularities on the surface of knit fabrics, known as horizontal bars, poses a challenge that requires a thorough understanding of both spinning and knitting processes. These bars, characterized by inconsistent color and shade variations, may arise from a combination of factors related to yarn properties, circular knitting machine manufacturing, and dyeing and finishing processes.

The origins of horizontal bars in knitted fabrics must be examined from both the spinning and weaving perspectives.

1. Batching of Raw Materials:

Inconsistencies in chemical and mechanical properties during material batching can lead to significant variations in the appearance of colored fabrics, resulting in regular patterns of color differences.

2. Raw Material Composition:

Uneven mixing or incorrect ratios in raw materials can lead to unstable yarn quality, manifesting as horizontal bars on the fabric surface.

3. Spinning Process Design:

Uneven yarn quality and defects such as cotton knots can introduce irregular horizontal bars during the spinning process.

4. Evenness of Sliver:

Poor sliver evenness within the same batch can result in single-bar defects on the fabric surface, causing an uneven appearance.

5. Yarn Twist:

Significant differences in yarn twist and fuzziness may result in uneven dyeing during the dyeing process, leading to color variations and horizontal bars on the fabric.

Analyzing the formation of horizontal bars from the knitting perspective involves considering factors such as:

Uneven Yarn Tension:

Controlling yarn tension during the knitting process is crucial to prevent variations in loop sizes, which can result in visible defects on the fabric surface.

Yarn Management:

Incorrect use or mixing of yarn batches in knitting can contribute to the appearance of horizontal bars on the fabric.

Besides these factors, operational issues in the spinning and knitting departments, such as improper machine handling, can also lead to the occurrence of horizontal bars.

Analytical Methods for Horizontal Bars in Knitted Fabrics:

Characterization of Bar Features:

Analyze the fabric's surface for smoothness, color variations, presence of defects, and the regularity of horizontal bars in terms of width and length.

Structural and Composition Analysis:

Perform yarn deconstruction to analyze knitting patterns, unravel twisted yarns, and identify fabric composition. For fabrics containing spandex, consider solvent treatment to dissolve and isolate the spandex for analysis.

Root Cause Verification:

Validate the identified reasons for the formation of horizontal bars through systematic verification, considering both spinning and knitting aspects.

Preventive Measures:

To avoid the occurrence of common horizontal bars in knitted fabrics, implement the following measures:

Accurate Raw Material Design:

Precisely design the blending process for raw materials, conduct regular checks on raw materials or semi-finished slivers, and prevent inaccuracies in the final blend.

Control Yarn Twist Evenness:

Minimize variations in yarn twist and residual torque to prevent uneven dyeing and subsequent color variations on the fabric.

Enhance Workshop Management:

Standardize warehouse management practices to prevent the misuse of yarn or the mixing of different batches.

Operational Standardization:

Standardize worker operations, conduct regular machine maintenance, and prevent human and mechanical errors that may lead to the formation of horizontal bars.

In conclusion, a comprehensive understanding of the theoretical and practical aspects of horizontal bar formation in knitted fabrics reveals that both spinning processes and production management play crucial roles. To proactively address and prevent the occurrence of horizontal bars in practical production, it is essential to accurately analyze raw material properties, optimize spinning processes, and enforce stringent production management practices in both spinning and knitting workshops.

Next: Causes and Solutions for Arc-shaped Fabric in Circular Knitting Machines

Previous: Troubleshooting Common Issues with Circular Knitting Machines

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.