Causes and Solutions for Needle Collisions in Circular Knitting Machines

Nov 11, 2023

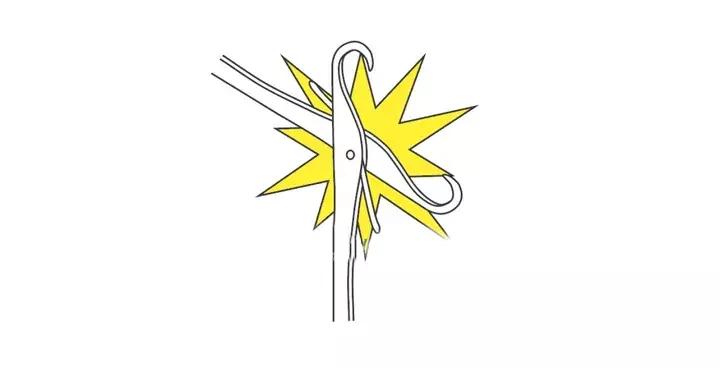

Needle collisions in circular knitting machines refer to instances where knitting needles, during the operation of the equipment, experience impacts or breakage of the needle shank. Typically, needle shank breakage is more common. If needle breakage occurs, it is abnormal, and when this happens, it is essential to determine if the needle broke at the knitting position or the side with more or fewer needle latches (indicating the collision position). This helps identify the specific location of the needle break on the sinker.

1. Issues with the Sinker:

(1) Loose or Tight Needle-Sinker Coordination: Excessive wear on the knitting needle or sinker can result in increased lateral movement, causing needle collisions. Some specialized materials may require thinner knitting needles in wider needle cylinders, increasing the risk of collisions.

(2) Insufficient or Excessive Sinker Groove Depth: If the sinker groove is too tight or too deep, it can impede the proper movement of the knitting needle, leading to needle collisions. The depth of the groove should ideally allow the knitting needle to be slightly below the sinker surface.

(3) Sinkers with Uneven Surfaces: Prolonged friction on sinkers can result in uneven surfaces, increasing the likelihood of needle collisions.

2. Triangle Issues:

(1) Lack of Bevel or Excessive Bevel: A lack of bevel or excessive bevel on the entry surface of the triangle can lead to needle collisions. An insufficiently smooth entry surface or excessive bevel can contribute to collisions.

(2) Excessive Slope Angle of the Triangle: Increasing the slope angle of the triangle enhances the force on the needle latch in the tangential direction during machine operation, making needle collisions more likely, particularly in flat-ground triangles.

(3) Excessive Gap Between Triangles: If the gap between triangles is too large, knitting needles may get caught between them, causing collisions. The gap between triangles should ideally not exceed the thickness of a single knitting needle, which is around 0.10-0.20mm.

(4) Irregular Surface of the Triangle: Prolonged friction on triangles can result in irregular surfaces, increasing the risk of needle collisions.

(5) Triangle Needle Channel Issues: Unprocessed broken needle shanks or narrow needle channels in triangles can contribute to needle collisions.

(6) Improper Installation of Triangles or Triangle Seats: Incorrectly installed triangles or seats, including protruding fixing screws or dirty surfaces during installation, can cause needle collisions.

(7) Material Issues or Improper Heat Treatment of Triangles: Soft or improperly heat-treated triangle materials can lead to impact resistance issues or brittle fractures, causing needle collisions.

(8) Non-Perpendicular Triangle Needle Channels: In normal conditions, the plane of the triangle needle channel should be perpendicular to the triangle's plane. Deviations can occur during milling, affecting the contact between knitting needles and triangle needle channels.

3. Other Causes:

(1) Quality Issues with Knitting Needles: Poor-quality knitting needles with low strength can result in needle collisions.

(2) Lack of Lubrication in Needle Channels: Insufficient lubrication in needle channels can increase friction and the risk of needle collisions.

(3) Presence of Moisture in Needle Oil: Moisture in needle oil can reduce lubrication effectiveness and lead to needle collisions.

(4) Excessive Clearance Between Needle Cylinders (Disks) and Triangles: Large clearances between needle cylinders (disks) and triangles can cause knitting needles to deviate from the correct path, resulting in collisions.

(5) Introduction of a Significant Amount of Lint or Yarn into the Needle Hook: Feeding a large amount of lint or tangled yarn into the needle hook can obstruct the descent of knitting needles during pressing, causing needle latch breakage.

(6) Excessive Jumping of the Needle Disk Position: Excessive jumping of the needle disk position can occur due to unstable equipment operation or misalignment of the needle disk, causing needle collisions.

(7) Excessive Gear Clearance or Damage to Unidirectional Bearings: Large gear clearances or damage to unidirectional bearings can result in reverse rotation during rapid stops, leading to needle collisions.

(8) Proper Adjustment of the Cloth Roll Machine: Relaxing the tension on the cloth roll machine appropriately can prevent needle collisions, especially in older machines with multiple issues.

In conclusion, addressing these causes and implementing proper maintenance procedures can significantly reduce the occurrence of needle collisions in circular knitting machines. Regular checks, lubrication, and adjustments are essential for ensuring smooth and trouble-free operation.

Next: Circular Knitting Machine: Function, Principles, and Working Proces

Previous: Maintenance of Circular Knitting Machines

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.