Circular Knitting Machine Organizational Structures

Nov 11, 2023

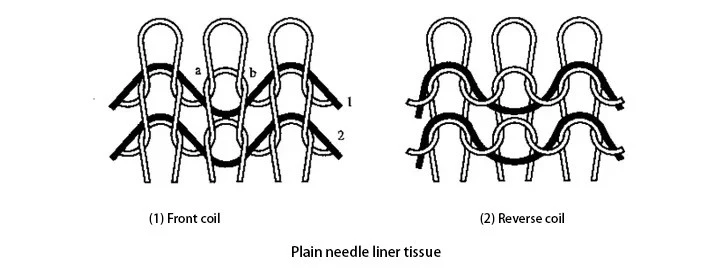

Circular knitting machine fabrics can be categorized into single jersey and double jersey.

Single Jersey: Fabric knitted using a single needle bed.

Double Jersey: Fabric knitted using a double needle bed.

Whether a knitted fabric is single jersey or double jersey depends on the knitting method.

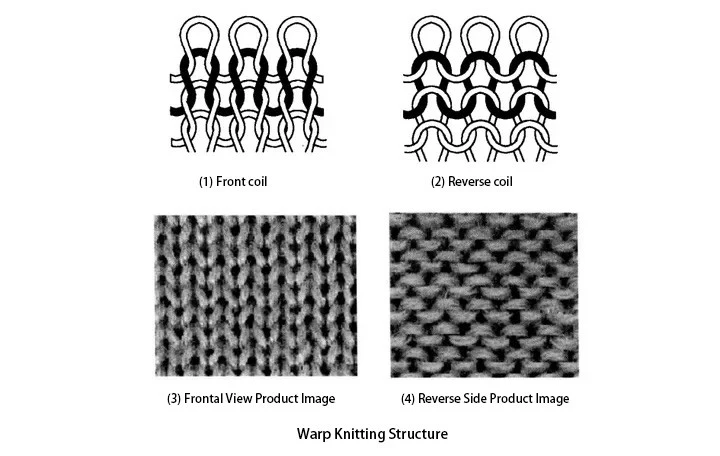

- Warp Knit Structure

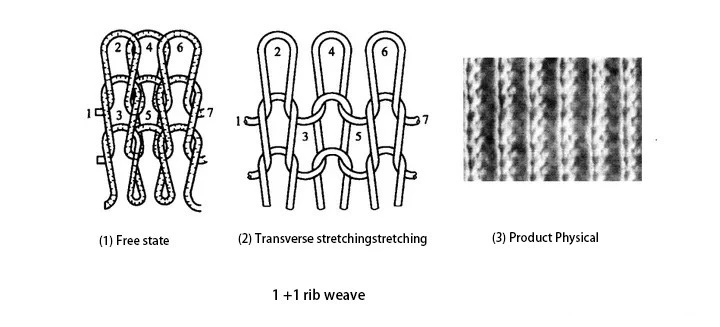

- Rib Knit Structure

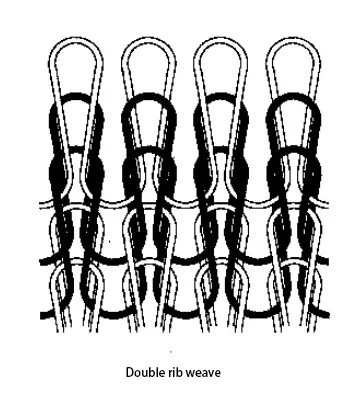

- Double Rib Knit Structure

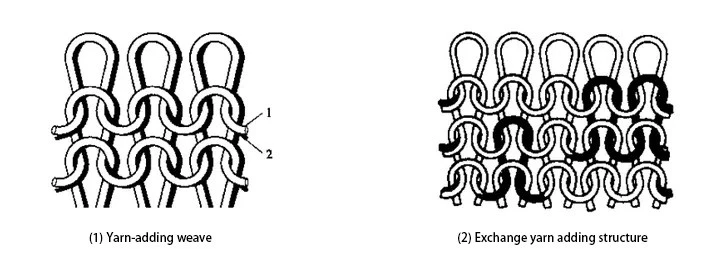

- Additional Yarn Structure

- Padding Structure

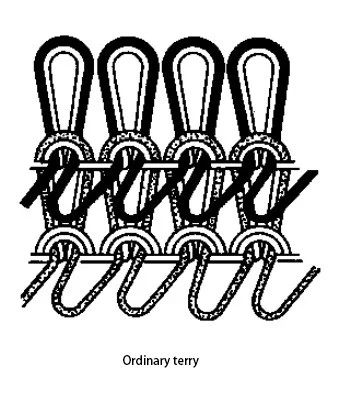

- Loop Pile Structure

- Color Bar Structure

In addition to the mentioned structures, other structures like single-faced pile structures, double-faced structures, plush loop structures, backing warp structures, additional warp structures, and backing structures can also create horizontal stripes on fabrics.

- Organizations with Vertical Stripe Effects

The vertical stripe effect is primarily achieved through changes in organizational structure. Various fabrics for outerwear can be designed with vertical stripe effects, including loop pile structures, ribbed composite structures, double-ribbed composite structures, and padded structures. Fabrics featuring vertical stripes formed by loop pile structures are suitable for producing spring and autumn clothing. Ribbed structures, such as ribbed tuck-stitch float structures, create vertical textured stripes on the fabric surface. Ribbed tuck-stitch structures have low lateral extensibility and excellent dimensional stability, making them suitable for sportswear and outerwear in spring and autumn. Additionally, the use of wide float structures can create vertical textured stripes on the fabric surface, resembling corduroy. Typically woven with low-elasticity polyester threads, these fabrics are ideal for manufacturing outerwear in fall and winter, though they may be prone to pilling and snagging due to the uneven coil structure, resulting in reduced fabric strength.

Furthermore, raised flower structures, loop pile structures, and additional yarn structures can also produce vertical stripe effects on fabrics.

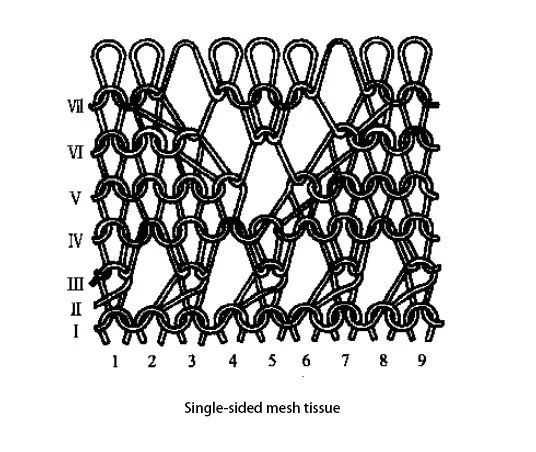

- Mesh Structure

Mesh-effect fabrics are widely used in T-shirts and spring/autumn outerwear. By interweaving knit stitches and looped stitches with elongated settling arcs, a mesh effect is formed, often referred to as pearl fabric. Depending on whether the number of plain knit stitches and looped stitches is approximately equal or unequal, various pearl fabrics can be created using an alternating chessboard-like arrangement. Fabrics with this structure exhibit excellent breathability. Double pearl fabrics, woven with combed cotton yarn, can be treated to achieve a sparkling mesh effect, resembling pearls. These fabrics are ideal for summer and spring/autumn clothing. Ribbed structures with added loop and float stitches create a honeycomb-shaped mesh effect, offering good breathability, low longitudinal and transverse extensibility, making them suitable for spring and autumn outerwear. Combining double-ribbed and loop structures creates a honeycomb mesh effect on the fabric surface. These fabrics are thicker than ribbed loop structures, have low extensibility, good resilience, structure, and dimensional stability, making them excellent materials for casual wear in spring and autumn. Fabrics with these structures are often used in moisture-wicking textiles.

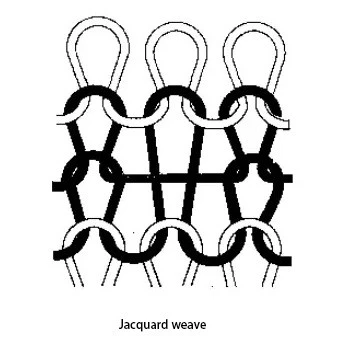

- Jacquard Structure

Jacquard structure involves placing yarns according to the desired pattern on selected needles to create patterns on the fabric. It can be categorized into single-faced and double-faced jacquard fabrics based on the organizational structure, and into solid color and multi-color jacquard fabrics based on color. There are also jacquard loop knit fabrics and jacquard rib knit fabrics. Materials used include low-elasticity polyester, nylon, elastic nylon, nylon filament, acrylic, wool, cotton, and polyester-cotton blends. Jacquard knitted fabrics exhibit clear patterns, rich designs, a thick texture, stable structure, low extensibility, minimal pilling, and a soft and elastic handfeel, making them excellent materials for knitted outerwear.

- Composite Structure

Composite structure involves combining two or more fabric structures. It can be a combination of different basic structures, varied changing structures, or different colored structures. Composite structures can be tailored to achieve the desired fabric structure based on the characteristics of each structure. Rib structures combined with plain knit structures form ribbed air layer structures, while double-rib structures combined with plain knit structures create double-rib air layer structures. Fabrics with these structures are dense, thick, elastic, well-insulated, and have low transverse extensibility, ensuring good dimensional stability. If the outer layer of the air layer structure is woven with cotton yarn and the inner lining with high-elasticity silk, it becomes an excellent material for thermal underwear. If different types of yarn are used on the front and reverse sides, it is especially suitable for outerwear.

Combining incomplete rib structures with plain knit structures forms a dot structure, creating a tight and stable fabric surface with distinct dot effects. Jacquard structures combined with loop pile structures form jacquard loop pile structures, allowing different types of yarn to be used on the front and reverse sides. The front side exhibits prominent color effects, high abrasion resistance, while the reverse side is soft with strong moisture absorption, making it an excellent material for knitted outerwear. Polyester-cotton fabrics woven from two different materials, with the front side displaying polyester (chemical fiber) and the reverse side displaying cotton (natural fiber), are stiff, wrinkle-resistant, abrasion-resistant, colorfast, and the inner layer is soft, moisture-absorbing, breathable, insulating, and static-resistant, providing a comfortable wearing experience. Single-faced polyester-cotton fabrics using plain knit additional yarn structures, and double-faced polyester-cotton fabrics often use rib, double-rib loop float structures, or air layer structures, suitable for making sportswear, jackets, and fitness pants.

- Brushed Knit Fabric

Brushed knit fabric, also known as flannel, refers to a knitted fabric with a dense layer of short and fine fuzz covering its surface. It is divided into single-sided flannel and double-sided flannel. Single-sided flannel is formed by brushing the back of a backing weave, while double-sided flannel is generally created by brushing both sides of a double-knit fabric. After dyeing, brushed knit fabric can be processed into various varieties, such as bleached, super white, solid color, printed, and more. It can also be woven with dyed or blended yarns to produce solid or color-woven products.

- Sheared Pile Fabric

Sheared pile fabric is produced by shearing the heads of the pile loops on the surface of a single-sided loop pile fabric and then brushing or pressing the pile to create a smooth pile surface, often referred to as velvet. Sheared pile fabric is typically made using chemical fibers for the fabric structure and using combed cotton, acrylic, polyester, or other fibers for the pile yarn. Various patterns, colors, and effects such as embossing or printing can be achieved through jacquard or colored yarns, as well as through shearing and pressing techniques, creating a variety of velvet designs.

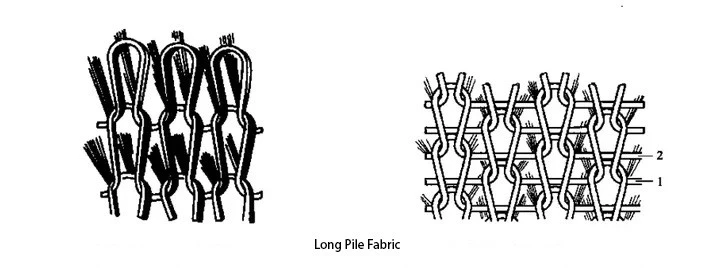

- Long Pile Fabric

Long pile fabric is an organization where fiber strips or yarns are fed into the weaving process along with the ground yarn, forming loops in the structure. Fibers attach to the fabric's reverse side in a tufted fashion. By weaving with a mixture of different synthetic fibers, the appearance resembles natural fur, earning it the nickname "artificial fur." Particularly, knitted artificial fur made from acrylic is lighter than natural fur, offering good insulation and wear resistance. The appearance closely mimics natural fur, and it is suitable for making winter outerwear.

Patterned organizations not only create various patterns on the knitted fabric to enhance its appearance but also alter the fabric's properties, such as reducing shedding, making the fabric denser, thicker, and more dimensionally stable. This provides rich material options for the fashionable and stylized production of knitted clothing.

Next: Common Causes of Fabric Breakage in Circular Knitting Machine Debugging

Previous: The China International Textile Machinery Exhibition 2023

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.