Common Causes of Fabric Breakage in Circular Knitting Machine Debugging

Nov 11, 2023

The cause of fabric breakage is often the result of yarn experiencing forces exceeding its tensile strength during the weaving process. This external force is influenced by numerous factors. Excluding the yarn's intrinsic strength, several situations related to the adjustment of circular knitting machines during the debugging process can contribute to fabric breakage:

Excessive Yarn Tension:

High yarn tension can lead to fabric breakage. When the needle depth (bend yarn amount) remains constant, reducing yarn feed speed increases yarn tension. If yarn tension approaches the breaking strength, fabric breakage occurs. As tension further increases, not only does fabric breakage intensify, but yarn may also break, causing machine stoppage.

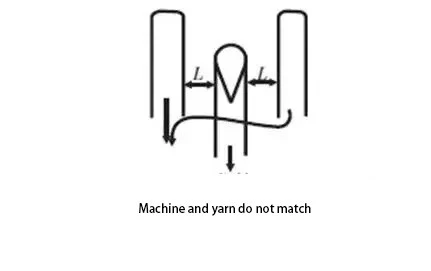

Mismatch of Machine Number and Yarn:

Each fixed needle cylinder has limitations on the range of yarn thickness it can accommodate. Yarn that is too thin compromises fabric stability, while overly thick yarn can easily cause fabric breakage.

When yarn is bent into a loop by knitting needles, it needs to smoothly release in the subsequent weaving process. If the loop length is shorter than the circumference of the closed needle hook, fabric breakage occurs. This phenomenon is more common in single-face machines.

Incorrect Placement of Yarn Guides:

Improper installation of yarn guides, too close to knitting needles, can result in yarn being squeezed between the guide and the needle. This creates tension, leading to fabric breakage.

Adjustment of Float Triangle Position:

In composite weave processes, such as cotton wool weaves, precise adjustment of the float triangle's entry and exit positions is crucial. Incorrect adjustment can lead to inadequate release of loops, causing fabric breakage.

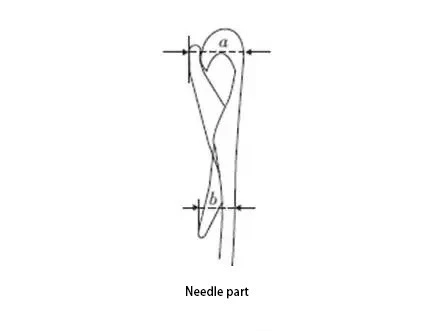

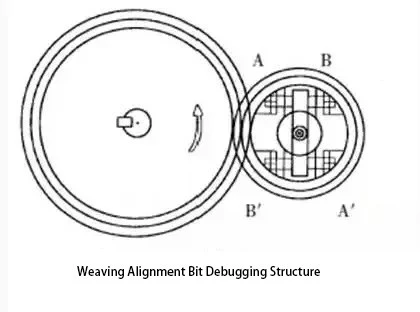

Adjustment of the Relative Positions of the Double-sided Circular Needle Plate and Needle Cylinder Triangle:

When knitting rib structures, the positions of the needle plate and needle cylinder triangles are generally adjusted to the fully back-eating position. This means that when the needle cylinder finishes knitting a stitch and starts moving horizontally, the needle plate needles begin to enter the needle plate groove. Alternatively, it can be adjusted to the opposing-eating position, where both the needle cylinder and needle plate needles eat yarn and knit simultaneously. Avoid adjusting to the middle position, where the needle plate needles start eating yarn while the needle cylinder needles are still rising after knitting a stitch. Typically, the back-knitting angle of the needle cylinder triangle in rib knitting is around 40°, while the needle plate triangle's pressing needle angle is around 53°. This ensures that the speed at which the needle cylinder needles release yarn is slower than the speed at which the needle plate needles eat yarn. If the needle cylinder needles release yarn while the needle plate needles eat yarn, it creates high tension in the yarn running between the cylinders, increasing the chances of forming holes.

When knitting jacquard fabrics, the irregular frequency of the needle cylinder needles due to needle selection makes it crucial to adjust the relative positions of the needle plate and needle cylinder triangles to the opposing-eating position rather than the back-eating position. In the back-eating position, the delayed yarn eating causes the yarn path to become tortuous, increasing friction between the yarn and needles, resulting in higher internal stress and hole formation. In some machines, due to the differences in the pressing needle angles of the needle plate and needle cylinder triangles or the selection of needle plate and needle cylinder needles, they may mutually leave each other simultaneously. Therefore, when observing the choice of the opposing-eating position, it should be based on the needles reaching the lowest point of pressing simultaneously.

For cotton pile structures or similar fabrics, where the number of stitches released is small, the choice of the relative positions of the needle plate and needle cylinder triangles is less sensitive. When knitting certain composite fabrics, several yarn feeding speeds are often used, and the matching between these speeds is crucial. If the coordination is unreasonable, it can result in inconsistent fabric amounts for each basic structure knitted at different speeds. When the tension from pulling and taking acts mostly on the basic structure knitting at a slower speed, it can easily lead to breakage due to high tension, forming holes. Simultaneously, the basic structure knitting at a faster speed, not receiving effective tension, may result in incomplete back-knitting, leading to fabric jamming. Therefore, the coordination of yarn feeding speeds between different basic structures must be reasonable.

In the weaving of composite fabrics with multiple yarn feed speeds, improper coordination can result in inconsistent fabric quantities. This, coupled with high tension, increases the risk of fabric breakage.

Improper Adjustment of Yarn Bending Depth:

For fabrics with looped structures, such as those with gathering rings, careful adjustment of the bending depth is required to avoid breaking the retained yarn loops.

Other Factors:

Additional factors such as misalignment of needle tongues, excessive needle wear, loose belt tension in yarn storage devices, high fabric tension, and tight needle slots can also contribute to fabric breakage.

In conclusion, addressing these common issues in circular knitting machine debugging is essential to ensure smooth fabric production and minimize the occurrence of fabric breakage.

Next: How to Choose a High-Quality Circular Knitting Machine

Previous: Circular Knitting Machine Organizational Structures

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.