Exploring the Double Jersey Transfer Jacquard Knitting Machine

Dec 06, 2024

On this page

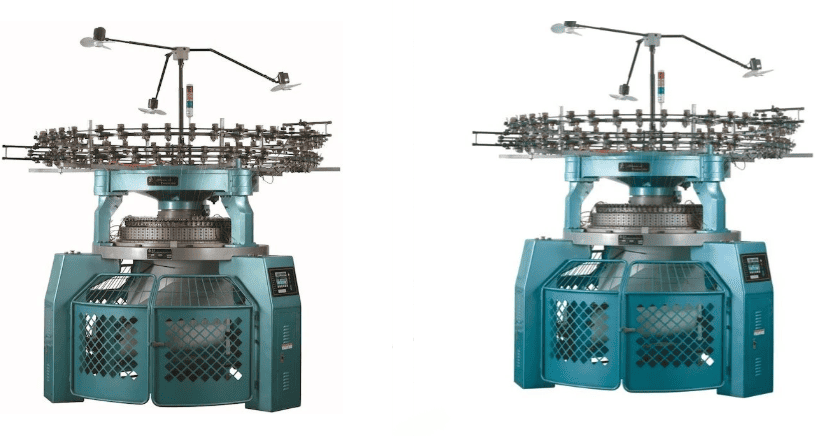

The textile industry continually evolves with advancements in technology, and the Double Jersey Transfer Jacquard Knitting Machine stands out as a remarkable innovation. Designed to deliver intricate patterns and layered fabric structures, this advanced circular knitting machine is a cornerstone for modern fabric production. In this article, we will explore what makes this machine unique, how its stitch transfer mechanism works, and the diverse fabrics it can produce.

The Double Jersey Transfer Jacquard Knitting Machine is an advanced circular knitting machine that combines functionality, precision, and creativity. Unlike conventional machines, it is specifically engineered to handle complex designs on double jersey fabrics, making it a valuable tool for manufacturers producing high-quality textiles.

This machine's standout feature is its ability to perform stitch transfers, which involves moving stitches between the front and back needle beds. This capability allows for creating intricate jacquard patterns, three-dimensional textures, and layered effects that traditional machines cannot achieve.

The fabrics produced using this machine are structured and stable, making them suitable for a wide range of applications, including:

• Fashionable garments with intricate designs.

• Home textiles such as decorative pillows and upholstery.

• Functional textiles for sportswear and medical applications.

With this machine, manufacturers can achieve both artistic and functional excellence in fabric production.

• Raised or embossed effects.

• Layered structures for enhanced durability or aesthetic appeal.

• Openwork designs for breathable fabrics.

This mechanism sets the Double Jersey Transfer Jacquard Knitting Machine apart, offering unparalleled flexibility for fabric designers. The versatility of the Double Jersey Transfer Jacquard Knitting Machine makes it suitable for producing a wide array of fabrics. Here are some examples: The ability to create intricate jacquard patterns and textured designs makes this machine ideal for high-end fashion garments. Designers can craft unique looks by combining traditional jacquard patterns with modern textural effects. • Dresses with layered patterns.

• Structured tops and blouses.

• Textured skirts and trousers. For home decor, the machine can produce durable and visually appealing fabrics that enhance interior aesthetics. The stitch transfer mechanism allows for robust designs that are both functional and stylish. • Upholstery fabrics with intricate details.

• Decorative pillowcases and bedspreads.

• Curtains with three-dimensional textures. The demand for functional textiles, such as sportswear and medical fabrics, is growing. This machine’s advanced capabilities can meet the need for breathable, flexible, and durable materials. • Sportswear with zoned ventilation.

• Compression garments with structured support.

• Medical textiles for wound care or orthopedic supports. Beyond conventional uses, this machine can also produce specialty fabrics for niche markets, such as automotive interiors, industrial filters, or artistic installations. • Automotive seat covers with jacquard designs.

• Flexible yet strong industrial meshes.

• Custom fabrics for artistic projects. The Double Jersey Transfer Jacquard Knitting Machine offers numerous benefits that make it a valuable investment for textile manufacturers: The stitch transfer mechanism allows for unparalleled creativity, enabling manufacturers to produce complex patterns and textures that stand out in the market.

This machine's standout feature is its ability to perform stitch transfers, which involves moving stitches between the front and back needle beds. This capability allows for creating intricate jacquard patterns, three-dimensional textures, and layered effects that traditional machines cannot achieve.

The fabrics produced using this machine are structured and stable, making them suitable for a wide range of applications, including:

• Fashionable garments with intricate designs.

• Home textiles such as decorative pillows and upholstery.

• Functional textiles for sportswear and medical applications.

With this machine, manufacturers can achieve both artistic and functional excellence in fabric production.

• Raised or embossed effects.

• Layered structures for enhanced durability or aesthetic appeal.

• Openwork designs for breathable fabrics.

This mechanism sets the Double Jersey Transfer Jacquard Knitting Machine apart, offering unparalleled flexibility for fabric designers. The versatility of the Double Jersey Transfer Jacquard Knitting Machine makes it suitable for producing a wide array of fabrics. Here are some examples: The ability to create intricate jacquard patterns and textured designs makes this machine ideal for high-end fashion garments. Designers can craft unique looks by combining traditional jacquard patterns with modern textural effects. • Dresses with layered patterns.

• Structured tops and blouses.

• Textured skirts and trousers. For home decor, the machine can produce durable and visually appealing fabrics that enhance interior aesthetics. The stitch transfer mechanism allows for robust designs that are both functional and stylish. • Upholstery fabrics with intricate details.

• Decorative pillowcases and bedspreads.

• Curtains with three-dimensional textures. The demand for functional textiles, such as sportswear and medical fabrics, is growing. This machine’s advanced capabilities can meet the need for breathable, flexible, and durable materials. • Sportswear with zoned ventilation.

• Compression garments with structured support.

• Medical textiles for wound care or orthopedic supports. Beyond conventional uses, this machine can also produce specialty fabrics for niche markets, such as automotive interiors, industrial filters, or artistic installations. • Automotive seat covers with jacquard designs.

• Flexible yet strong industrial meshes.

• Custom fabrics for artistic projects. The Double Jersey Transfer Jacquard Knitting Machine offers numerous benefits that make it a valuable investment for textile manufacturers: The stitch transfer mechanism allows for unparalleled creativity, enabling manufacturers to produce complex patterns and textures that stand out in the market.

With its advanced automation and precision, the machine can produce high-quality fabrics at faster speeds compared to traditional knitting systems.

From fashion to functional textiles, this machine caters to a wide range of fabric types and applications, ensuring adaptability to changing market demands.

By enabling intricate designs in a single production process, the machine reduces the need for additional finishing steps, saving time and costs.

Advanced controls ensure that every fabric produced meets strict quality standards, providing reliability and reducing waste.

Modern Double Jersey Transfer Jacquard Knitting Machines are equipped with cutting-edge technology to maximize performance. Here are some of the key features:

These systems ensure precise pattern control, enabling complex designs with ease.

Integrated software and touch-screen controls make it easy to upload designs, monitor production, and adjust settings in real-time.

Enhanced cam systems and durable components allow for faster knitting speeds without compromising quality.

Manufacturers can tailor stitch density, transfer frequency, and other parameters to meet specific production needs.

Built with high-quality materials, these machines are designed to handle demanding production schedules while minimizing maintenance requirements.

The textile industry is continuously evolving, and Double Jersey Transfer Jacquard Knitting Machines are no exception. Here are some trends shaping the future of this technology:

The integration of artificial intelligence (AI) and Internet of Things (IoT) technology allows for predictive maintenance, real-time analytics, and smarter production planning.

With growing environmental awareness, these machines are being used to create eco-friendly textiles using recycled or biodegradable materials.

Advanced software is making it easier than ever to create and upload digital patterns, enabling rapid prototyping and customization.

Manufacturers are developing more compact machines that maintain high performance while saving space in production facilities.

Future models may combine knitting, weaving, and other fabric production techniques into a single system, further enhancing versatility.

The Double Jersey Transfer Jacquard Knitting Machine represents a leap forward in textile manufacturing, combining precision, versatility, and efficiency. Its ability to produce intricate jacquard patterns and layered fabrics opens up endless possibilities for designers and manufacturers alike.

Whether you are in fashion, home textiles, or functional fabrics, this machine is a game-changer, enabling innovation and excellence in every product it touches. As technology advances, the potential of these machines will only grow, solidifying their place as an essential tool in the modern textile industry.

Whether you are in fashion, home textiles, or functional fabrics, this machine is a game-changer, enabling innovation and excellence in every product it touches. As technology advances, the potential of these machines will only grow, solidifying their place as an essential tool in the modern textile industry.

Next: Advancing Textile Production with the Jacquard Circular Knitting Machine

Previous: How Does a Rib Circular Knitting Machine Work?

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links