How to Choose a High-Quality Circular Knitting Machine

Nov 11, 2023

Circular knitting machines belong to precision machinery, and the coordination of each system is crucial. The shortcomings of each system will become the performance limit of the machine. This is why, despite the seemingly simple production of circular knitting machines, there are only a few brands that excel in the market.

Many customers fall into a misconception when selecting circular knitting machines, focusing only on visible brand configurations such as yarn storage and needles, often overlooking the most critical aspects of the machine. Therefore, sometimes purchased machines are like small shrimps equipped with large crab claws – they may look luxurious, but the investment might not be practical.

Today, we will break down and discuss in detail what constitutes a balanced and stable machine, covering aspects such as the support structure, knitting system, cleaning system, transmission mechanism, lubrication system, yarn feeding system, and pulling mechanism.

Support Structure (Frame):

The support structure is like the skeleton of the human body; a machine with porous and loose castings will lack stability. Vibrations, even slight ones, during high-speed operation can affect the final fabric appearance. Natural aging is crucial for castings, involving exposing them to outdoor elements to release residual stresses and achieve stable precision.

Knitting System:

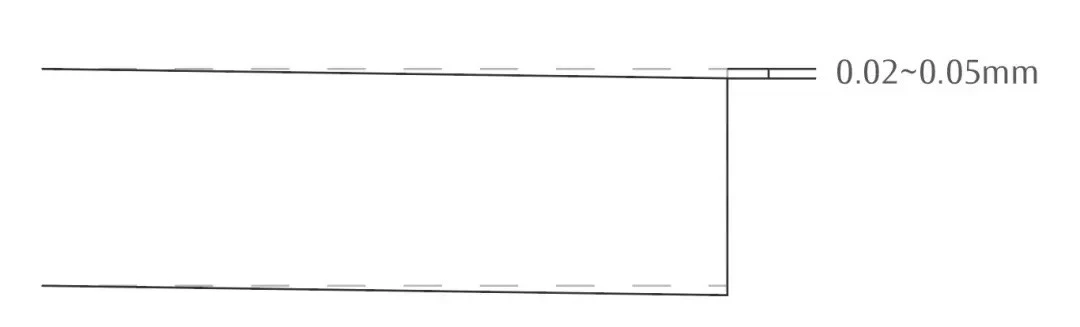

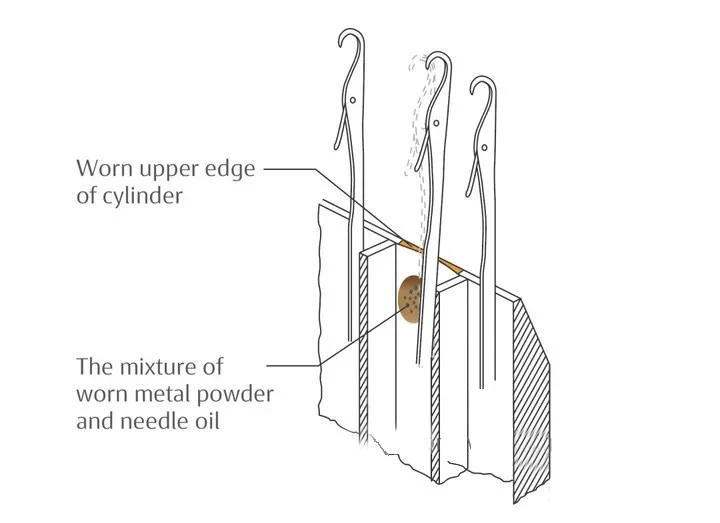

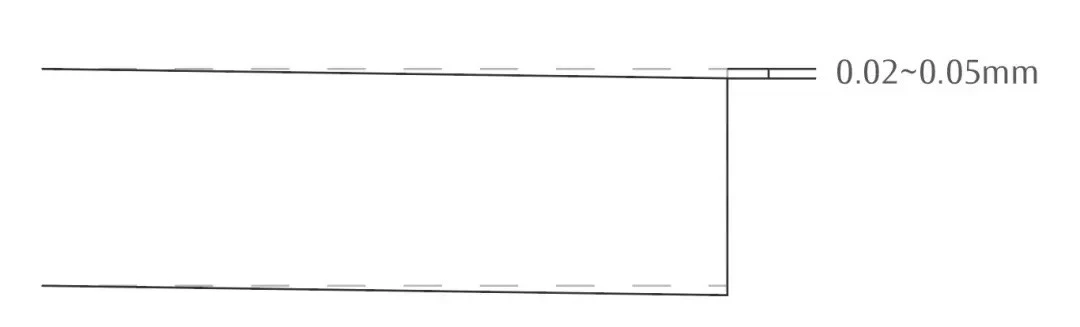

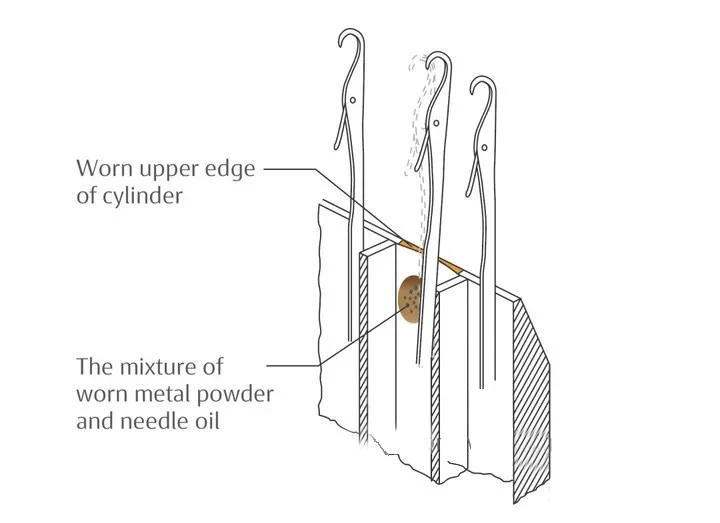

Needle Cylinder: The material of the needle cylinder is crucial, as it undergoes repeated friction from the knitting needles. Choosing a high-quality material, such as quick-cutting alloy steel treated with heat, ensures durability.

Lubrication System:

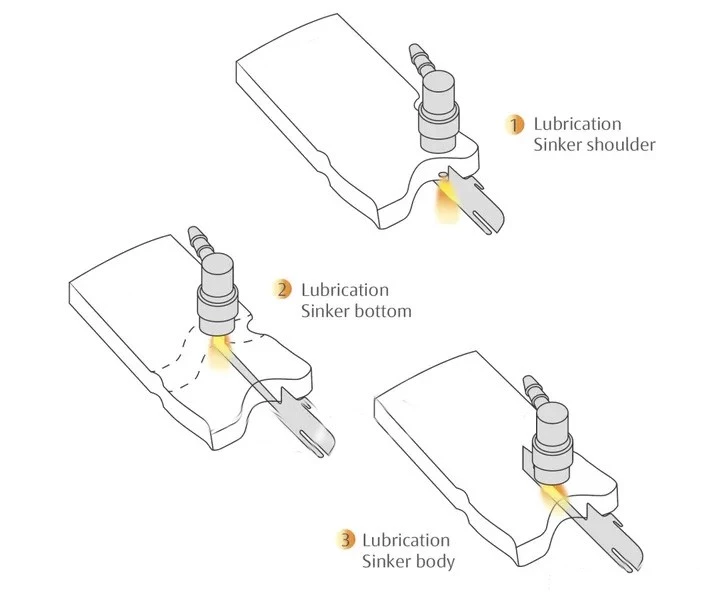

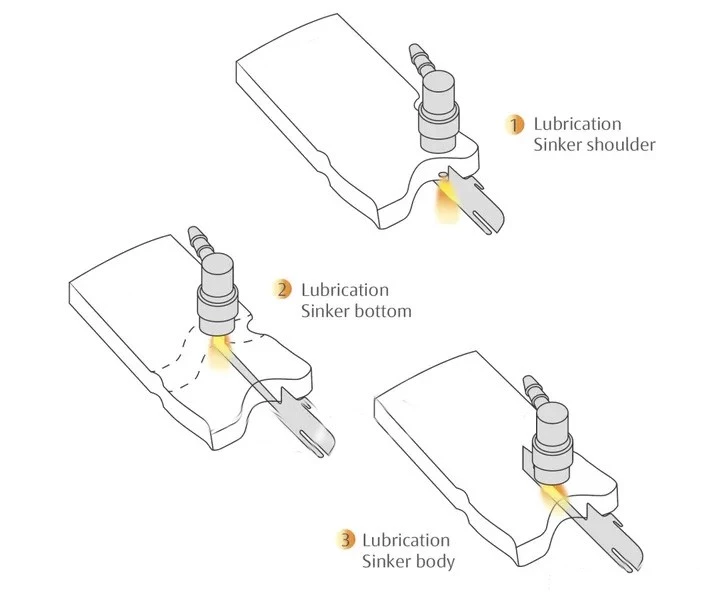

Adequate lubrication is essential for the longevity of sinkers and needles, reducing maintenance frequency and operational costs. Proper lubrication of sinkers' shoulder, heel, and body is crucial. The position of the oil nozzle is key, and an air-oil mixture sprayed on the needle hooks and tongues ensures cleanliness and flexibility.

Cleaning System:

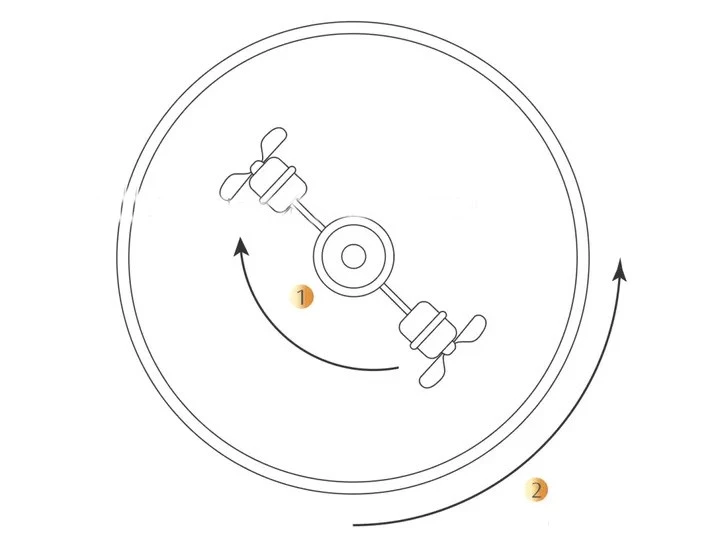

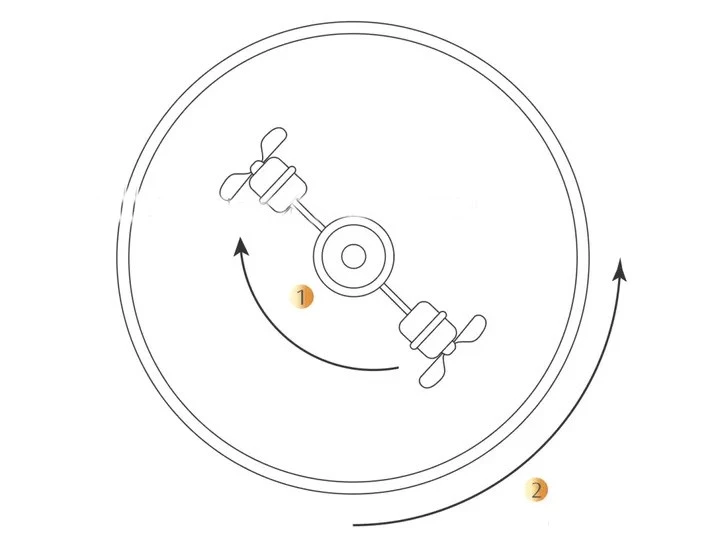

The cleaning system helps prolong cleaning intervals, reduce maintenance efforts, and minimize downtime, enhancing overall production efficiency. Optimal fan design, such as reverse centrifugal dust removal, ensures even and extended contact with dust removal points.

Yarn Feeding System:

While yarn storage units are commonly considered, the yarn rack is often overlooked. Sturdy materials, like thick square steel and solid supports, contribute to a more stable yarn feeding system, preventing jitter during high-speed operation and preserving fabric appearance.

Transmission Mechanism:

Choosing stable and reliable brands for the motor and frequency converter is crucial. Synchronous belts with stable transmission ratios contribute to reliable performance. Bearings, though often overlooked, play a crucial role in various systems and warrant detailed inquiry into the manufacturer's choice.

Pulling Mechanism:

Shock Absorption: In addition to the number of sections and the uniformity and tension of the cloth roller, a good shock absorption system can prolong the life of the cloth roller gearbox and reduce wear on large plate gears.

Installation Precision: Ensuring that the machine is assembled strictly according to installation precision requirements is crucial. Precision reflects the material grade and installation level.

Meeting these basic requirements represents the foundation of machine precision and quality. Another crucial point in choosing a manufacturer is their research and development (R&D) capabilities, especially when unique fabric structures and appearances are required. R&D capabilities determine how the machine's performance can be maximized, considering factors such as upper and lower plate cam curves, sinker throat depth, and coordination of timing, needle pressure, and tension, among others, for optimizing comprehensive performance.

In summary, a successful circular knitting machine requires attention to the fundamental aspects mentioned above and the manufacturer's research and development capabilities for achieving optimal performance in various fabric applications.

Many customers fall into a misconception when selecting circular knitting machines, focusing only on visible brand configurations such as yarn storage and needles, often overlooking the most critical aspects of the machine. Therefore, sometimes purchased machines are like small shrimps equipped with large crab claws – they may look luxurious, but the investment might not be practical.

Today, we will break down and discuss in detail what constitutes a balanced and stable machine, covering aspects such as the support structure, knitting system, cleaning system, transmission mechanism, lubrication system, yarn feeding system, and pulling mechanism.

Support Structure (Frame):

The support structure is like the skeleton of the human body; a machine with porous and loose castings will lack stability. Vibrations, even slight ones, during high-speed operation can affect the final fabric appearance. Natural aging is crucial for castings, involving exposing them to outdoor elements to release residual stresses and achieve stable precision.

Knitting System:

Needle Cylinder: The material of the needle cylinder is crucial, as it undergoes repeated friction from the knitting needles. Choosing a high-quality material, such as quick-cutting alloy steel treated with heat, ensures durability.

Lubrication System:

Adequate lubrication is essential for the longevity of sinkers and needles, reducing maintenance frequency and operational costs. Proper lubrication of sinkers' shoulder, heel, and body is crucial. The position of the oil nozzle is key, and an air-oil mixture sprayed on the needle hooks and tongues ensures cleanliness and flexibility.

Cleaning System:

The cleaning system helps prolong cleaning intervals, reduce maintenance efforts, and minimize downtime, enhancing overall production efficiency. Optimal fan design, such as reverse centrifugal dust removal, ensures even and extended contact with dust removal points.

Yarn Feeding System:

While yarn storage units are commonly considered, the yarn rack is often overlooked. Sturdy materials, like thick square steel and solid supports, contribute to a more stable yarn feeding system, preventing jitter during high-speed operation and preserving fabric appearance.

Transmission Mechanism:

Choosing stable and reliable brands for the motor and frequency converter is crucial. Synchronous belts with stable transmission ratios contribute to reliable performance. Bearings, though often overlooked, play a crucial role in various systems and warrant detailed inquiry into the manufacturer's choice.

Pulling Mechanism:

Shock Absorption: In addition to the number of sections and the uniformity and tension of the cloth roller, a good shock absorption system can prolong the life of the cloth roller gearbox and reduce wear on large plate gears.

Installation Precision: Ensuring that the machine is assembled strictly according to installation precision requirements is crucial. Precision reflects the material grade and installation level.

Meeting these basic requirements represents the foundation of machine precision and quality. Another crucial point in choosing a manufacturer is their research and development (R&D) capabilities, especially when unique fabric structures and appearances are required. R&D capabilities determine how the machine's performance can be maximized, considering factors such as upper and lower plate cam curves, sinker throat depth, and coordination of timing, needle pressure, and tension, among others, for optimizing comprehensive performance.

In summary, a successful circular knitting machine requires attention to the fundamental aspects mentioned above and the manufacturer's research and development capabilities for achieving optimal performance in various fabric applications.

Next: Circular Knitting Machine: Causes and Elimination of Stoppage Marks

Previous: Common Causes of Fabric Breakage in Circular Knitting Machine Debugging

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links