How to Choose Scale Adjustment Buttons for Circular Knitting Machines?

Feb 01, 2024

Circular weft knitting machines, specifically circular knitting machines, feature various types of scale adjustment buttons. The selection of these buttons plays a crucial role in achieving precise adjustments during fabric production. This article explores the common types of scale adjustment knobs, outlining their designs, applications, advantages, and drawbacks.

Common scale adjustment knobs can be divided into three types.

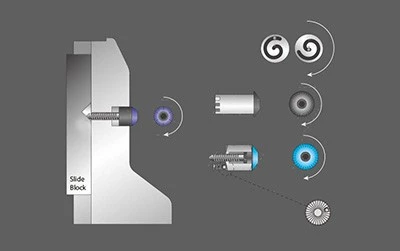

The first type is the screw-adjustable design, where the adjusting rod is integrated with the knob. By rotating the knob, the screw drives the adjustment knob in and out. The screw, with a conical surface, presses against the slider's conical surface, causing the slider and the mountain angle fixed on it to move downward. Applicable in a wide range, it allows for high-precision adjustments. Advantages include a combination of character code accuracy and high precision, suitable for both beginners and experts. The drawback is that when adjusting the fabric organization, the different depths of needle pressure may affect the uniformity of the appearance.

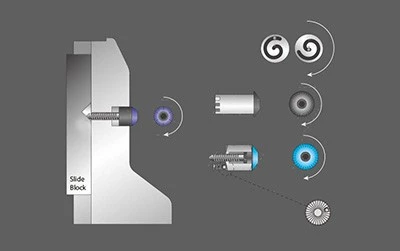

The second type is the spring screw type. In this design, the built-in adjusting rod moves in and out through rotation. Similar to the screw-adjustable design, the screw with a conical surface presses against the slider's conical surface, causing the slider and the mountain angle fixed on it to move downward. This type is versatile, meeting mid to high requirements. Advantages include a neater appearance due to non-whole movement, and there is audible feedback and tactile assistance during adjustment. The drawback is that it requires a higher skill level for the adjustment technician or may need to use a dial indicator. Since it is not an integrated design, the scales and internal adjustments rotate separately, and the scale dial may shift, leading to inaccurate character code positioning.

The third type is the Archimedean type. In this design, rotating the adjustment knob drives a pin on the slider through a constant pitch helix, causing the slider and the fixed mountain angle on it to move downward. Due to structural design reasons, the Archimedean-style adjustment knob has a shorter stroke. Therefore, each scale slider has a larger movement range, making it difficult to adjust precisely when dealing with fine needles requiring accuracy down to 1-2 threads or fabrics with high requirements. Suitable for quick rough adjustments, it is ideal for yarns insensitive to fabric surfaces, such as cotton yarn. Advantages include simplicity, speed, and suitability for beginners with low requirements for adjustment technicians. The drawback is the short stroke, making precise adjustments difficult and increasing the likelihood of dead zones. Reducing the total range of motion, for example, to 100 scales, can achieve precision to 3.3 scales per unit, but shortening the stroke also narrows the machine's application range.

In conclusion, the choice of scale adjustment buttons in circular weft knitting machines involves considerations of design, versatility, and precision. Whether opting for the screw-adjustable, spring screw, or Archimedean type, manufacturers must weigh the requirements of their fabric production, the expertise of their technicians, and the desired level of precision. Each type brings its unique characteristics to the table, influencing the appearance and uniformity of the final fabric output. By understanding these variations, manufacturers can make informed decisions to optimize the performance of their circular weft knitting machines.

Common scale adjustment knobs can be divided into three types.

The first type is the screw-adjustable design, where the adjusting rod is integrated with the knob. By rotating the knob, the screw drives the adjustment knob in and out. The screw, with a conical surface, presses against the slider's conical surface, causing the slider and the mountain angle fixed on it to move downward. Applicable in a wide range, it allows for high-precision adjustments. Advantages include a combination of character code accuracy and high precision, suitable for both beginners and experts. The drawback is that when adjusting the fabric organization, the different depths of needle pressure may affect the uniformity of the appearance.

The second type is the spring screw type. In this design, the built-in adjusting rod moves in and out through rotation. Similar to the screw-adjustable design, the screw with a conical surface presses against the slider's conical surface, causing the slider and the mountain angle fixed on it to move downward. This type is versatile, meeting mid to high requirements. Advantages include a neater appearance due to non-whole movement, and there is audible feedback and tactile assistance during adjustment. The drawback is that it requires a higher skill level for the adjustment technician or may need to use a dial indicator. Since it is not an integrated design, the scales and internal adjustments rotate separately, and the scale dial may shift, leading to inaccurate character code positioning.

The third type is the Archimedean type. In this design, rotating the adjustment knob drives a pin on the slider through a constant pitch helix, causing the slider and the fixed mountain angle on it to move downward. Due to structural design reasons, the Archimedean-style adjustment knob has a shorter stroke. Therefore, each scale slider has a larger movement range, making it difficult to adjust precisely when dealing with fine needles requiring accuracy down to 1-2 threads or fabrics with high requirements. Suitable for quick rough adjustments, it is ideal for yarns insensitive to fabric surfaces, such as cotton yarn. Advantages include simplicity, speed, and suitability for beginners with low requirements for adjustment technicians. The drawback is the short stroke, making precise adjustments difficult and increasing the likelihood of dead zones. Reducing the total range of motion, for example, to 100 scales, can achieve precision to 3.3 scales per unit, but shortening the stroke also narrows the machine's application range.

In conclusion, the choice of scale adjustment buttons in circular weft knitting machines involves considerations of design, versatility, and precision. Whether opting for the screw-adjustable, spring screw, or Archimedean type, manufacturers must weigh the requirements of their fabric production, the expertise of their technicians, and the desired level of precision. Each type brings its unique characteristics to the table, influencing the appearance and uniformity of the final fabric output. By understanding these variations, manufacturers can make informed decisions to optimize the performance of their circular weft knitting machines.

Next: How to Produce a Knitted Clothing?

Previous: Circular Knitting Machine Pulling-up Device and Presser Foot

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links