How to Choose Your First Circular Knitting Machine

Oct 29, 2024

On this page

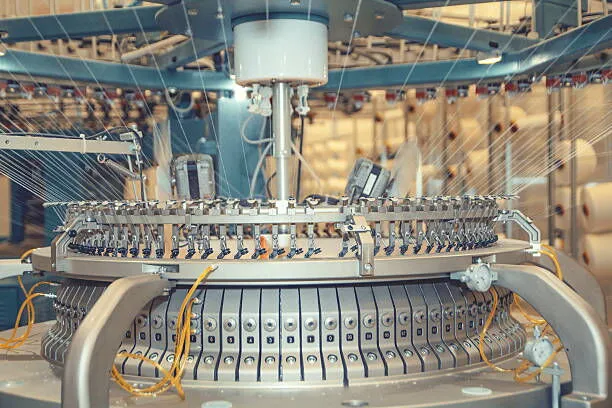

Starting with a new circular knitting machine can be an exciting step for expanding your production capabilities or venturing into knitting. However, choosing the right machine is crucial to ensure that it meets your specific needs and supports your business goals. This guide will walk you through seven key steps for selecting your first circular knitting machine.

The type of yarn you plan to use is also critical. Some machines handle fine, delicate yarns better, while others are suited for thicker, more durable yarns. Carefully outlining these production needs helps narrow down machine options that align with your specific requirements. Once you have a clear idea of your production requirements, it’s time to set a realistic budget. Circular knitting machines range widely in price depending on factors like machine size, production capabilities, automation features, and build quality. While it may be tempting to go for a cheaper option, keep in mind that investing in a quality machine will pay off in the long run. High-quality machines not only perform better but are also more durable, require less maintenance, and often come with better support from manufacturers.

Consider the total cost of ownership, including initial purchase price, potential installation fees, ongoing maintenance, and parts replacement. A budget that accounts for these aspects will give you a clearer picture of what you can afford and ensure you’re making a smart investment. Finding a reputable manufacturer is essential to ensure product quality, performance, and long-term support. Research manufacturers with a proven track record in the circular knitting machine industry and review feedback from other users. Look for brands known for their reliability, customer service, and innovation in knitting technology.

Well-established brands often provide comprehensive support, from technical assistance to training resources, which can be invaluable as you start using your new machine. Don’t hesitate to ask for recommendations or read reviews online to gather insights on the most trusted names in the industry. Choosing a reputable manufacturer also typically means better warranties and access to parts, making maintenance easier over the machine's lifetime. When you have shortlisted potential machines, it’s essential to thoroughly evaluate their specifications to see if they meet your requirements. Pay attention to key factors such as:

The type of yarn you plan to use is also critical. Some machines handle fine, delicate yarns better, while others are suited for thicker, more durable yarns. Carefully outlining these production needs helps narrow down machine options that align with your specific requirements. Once you have a clear idea of your production requirements, it’s time to set a realistic budget. Circular knitting machines range widely in price depending on factors like machine size, production capabilities, automation features, and build quality. While it may be tempting to go for a cheaper option, keep in mind that investing in a quality machine will pay off in the long run. High-quality machines not only perform better but are also more durable, require less maintenance, and often come with better support from manufacturers.

Consider the total cost of ownership, including initial purchase price, potential installation fees, ongoing maintenance, and parts replacement. A budget that accounts for these aspects will give you a clearer picture of what you can afford and ensure you’re making a smart investment. Finding a reputable manufacturer is essential to ensure product quality, performance, and long-term support. Research manufacturers with a proven track record in the circular knitting machine industry and review feedback from other users. Look for brands known for their reliability, customer service, and innovation in knitting technology.

Well-established brands often provide comprehensive support, from technical assistance to training resources, which can be invaluable as you start using your new machine. Don’t hesitate to ask for recommendations or read reviews online to gather insights on the most trusted names in the industry. Choosing a reputable manufacturer also typically means better warranties and access to parts, making maintenance easier over the machine's lifetime. When you have shortlisted potential machines, it’s essential to thoroughly evaluate their specifications to see if they meet your requirements. Pay attention to key factors such as:

The gauge (or number of needles per inch) and cylinder size determine the type of fabrics the machine can produce. A higher gauge is suitable for fine fabrics, while a lower gauge is ideal for thicker materials.

Machines vary in terms of revolutions per minute (RPM). A faster machine can produce more fabric in less time, which is beneficial for high-volume production but may not be as critical for smaller-scale operations.

If you’re producing complex patterns, consider machines that offer advanced patterning features, such as jacquard or ribbed knitting.

Machines with energy-efficient features can reduce your operating costs over time. Look for options that minimize power usage without compromising performance.

Review these specifications carefully to ensure they align with the type of production you plan to do and the quality of the fabric you want to achieve.

Review these specifications carefully to ensure they align with the type of production you plan to do and the quality of the fabric you want to achieve.

Learning to operate a circular knitting machine effectively is essential, especially if this is your first machine. Many reputable manufacturers offer training and technical support to help you get started and address any challenges that arise during production. This support can be in the form of in-person training, online tutorials, or access to a knowledgeable support team.

Ongoing technical support is equally important, as it helps troubleshoot any issues that may occur and ensures minimal downtime. When choosing a machine, inquire about the manufacturer’s support options and ask if they offer warranties or service packages that cover repairs or replacements. Access to quality support can make a significant difference in your operational efficiency and help you make the most of your investment.

Ongoing technical support is equally important, as it helps troubleshoot any issues that may occur and ensures minimal downtime. When choosing a machine, inquire about the manufacturer’s support options and ask if they offer warranties or service packages that cover repairs or replacements. Access to quality support can make a significant difference in your operational efficiency and help you make the most of your investment.

When selecting your first knitting machine, think about your long-term goals. While it’s important to find a machine that fits your current needs, it’s equally crucial to consider whether it can support your business as it grows. If you anticipate expanding your product line or increasing production volume in the future, consider machines that offer scalability or upgrade options.

Some manufacturers offer modular systems that allow you to add new features or upgrade parts as your needs evolve. For instance, you might start with a machine designed for single-knit fabric but later want to incorporate double-knit capabilities. Planning for future growth ensures that your investment will continue to serve your business even as your demands change.

Some manufacturers offer modular systems that allow you to add new features or upgrade parts as your needs evolve. For instance, you might start with a machine designed for single-knit fabric but later want to incorporate double-knit capabilities. Planning for future growth ensures that your investment will continue to serve your business even as your demands change.

Finally, a product demonstration can provide valuable insight into a machine’s capabilities and suitability for your operations. Many manufacturers or distributors offer live demonstrations or online sessions that allow you to see the machine in action. This is an opportunity to observe the machine’s speed, the ease of setting up different patterns, and how it handles different types of yarn.

During the demonstration, ask any questions you have about operating the machine, maintenance requirements, and how it performs under various production scenarios. A hands-on experience with the machine—or even just seeing it operated by an expert—can help confirm whether it’s the right choice for you.

During the demonstration, ask any questions you have about operating the machine, maintenance requirements, and how it performs under various production scenarios. A hands-on experience with the machine—or even just seeing it operated by an expert—can help confirm whether it’s the right choice for you.

Choosing your first circular knitting machine is a significant decision that requires careful planning and research. By understanding your production requirements, setting a practical budget, researching reputable manufacturers, and reviewing machine specifications, you can make an informed choice. Additionally, considering training, support, future scalability, and arranging a product demonstration will help ensure that the machine you choose is well-suited to your needs and business goals. With the right knitting machine, you’ll be well-equipped to produce high-quality fabrics and grow your knitting operation successfully.

Next: Best Lower-Impact Fabrics and Fibres for Sustainable Fashion

Previous: Operation Instructions for Circular Knitting Machines

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links