How to Maintain Circular Knitting Machines

Oct 17, 2024

On this page

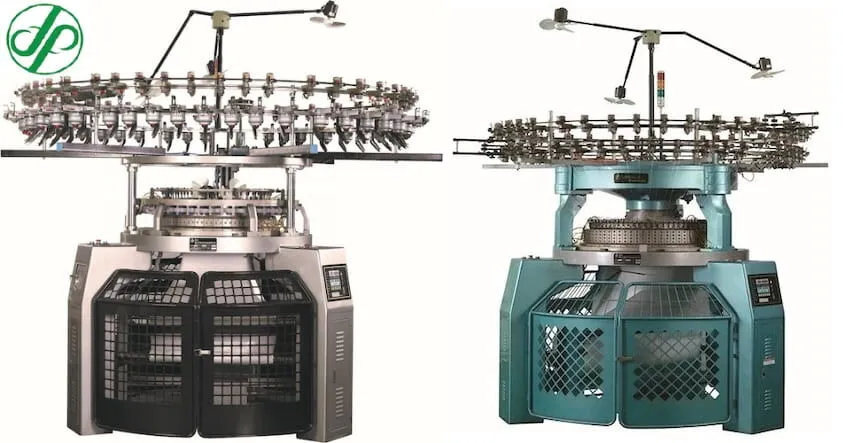

Routine maintenance of circular knitting machines is essential for extending their lifespan and ensuring optimal performance. Proper upkeep not only improves the quality of knitted fabrics but also reduces the likelihood of unexpected breakdowns. Here, we outline some recommended daily maintenance measures to help you keep your circular knitting machines in top condition.

Regular cleaning is crucial for the longevity and performance of your circular knitting machine. Accumulated dust, dirt, and impurities can adversely affect the machine's operation and the quality of the final product. Here are some tips for effective cleaning:

Choose a clean cloth and suitable cleaning agents specifically designed for textile machinery. Avoid harsh chemicals that could damage the machine's components.

Pay special attention to areas prone to dirt buildup, such as the housing, needles, and yarn guides. Ensure that both the exterior and interior parts of the machine are thoroughly cleaned.

Establish a cleaning routine based on your production schedule. For high-output environments, more frequent cleanings may be necessary.

Proper lubrication is vital for maintaining the functionality of circular knitting machines. Regularly checking and replenishing the lubrication system will help prevent wear and tear on moving parts. Here’s how to manage lubrication effectively:

Periodically inspect the oil or grease levels in the machine's lubrication system. Insufficient lubrication can lead to increased friction and potential damage.

Refer to the instruction manual for the recommended lubrication schedule and types of lubricants to use. Different machines may have specific requirements.

Regularly replace the lubricant to ensure it remains effective. Dirty or degraded lubricant can cause more harm than good.

Circular knitting machines generate heat during prolonged operation. It’s essential to monitor temperature levels to prevent overheating, which can lead to machine failure. Here are some strategies for managing heat:

Make sure the machine is located in a well-ventilated area. Good airflow helps dissipate heat and keeps the machine operating within safe temperature limits.

Avoid running the machine continuously for long periods. Schedule breaks to allow the equipment to cool down, especially during extensive production runs.

If necessary, consider implementing additional cooling solutions, such as fans or air conditioning, to maintain optimal operating conditions.

A reliable power supply is essential for the safe operation of your circular knitting machine. Regularly inspect the electrical components to ensure everything is functioning correctly:

Examine the power cord for any signs of wear, damage, or fraying. A damaged power cord can pose safety risks and affect machine performance.

Ensure all electrical connections are secure and free from corrosion. Loose connections can lead to power fluctuations and machine malfunctions.

If any issues are detected, such as a damaged power cord or connector, replace them immediately to avoid further complications.

Safety is paramount when operating any machinery, including circular knitting machines. Implementing safety measures can prevent accidents and injuries:

Operators should wear appropriate PPE, such as safety gloves and ear protection, to minimize the risk of injury while working.

Ensure that all operators are adequately trained in machine safety protocols and emergency procedures. Knowledgeable staff are less likely to make unsafe decisions.

Create and enforce safety protocols, including machine shutdown procedures, to ensure a safe working environment.

In addition to daily maintenance, regular inspections of the circular knitting machine are crucial for identifying potential issues before they escalate:

Regularly check the machine's performance metrics, such as stitch quality and speed, to detect any irregularities.

Check for signs of wear or damage on critical components, such as needles, gears, and belts. Early detection can prevent costly repairs later.

Depending on the brand and model, consider scheduling periodic professional maintenance to address complex issues or perform comprehensive checks.

Routine maintenance of circular knitting machines is essential for ensuring their longevity and optimal performance. By implementing these recommended daily maintenance measures—cleaning, lubrication, high-temperature protection, power supply checks, safety precautions, and regular inspections—you can significantly reduce the risk of breakdowns and improve the overall efficiency of your knitting operations.

Keep in mind that specific brands and models may have unique maintenance requirements, so it’s always a good idea to consult the manufacturer's manual for additional guidance. With diligent care and attention, your circular knitting machines can continue to deliver high-quality results for years to come.

Keep in mind that specific brands and models may have unique maintenance requirements, so it’s always a good idea to consult the manufacturer's manual for additional guidance. With diligent care and attention, your circular knitting machines can continue to deliver high-quality results for years to come.

Next: Jacquard Fabric: A Comprehensive Guide

Previous: The Crucial Role of Knitting Oil in Circular Knitting Machine Operations

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links