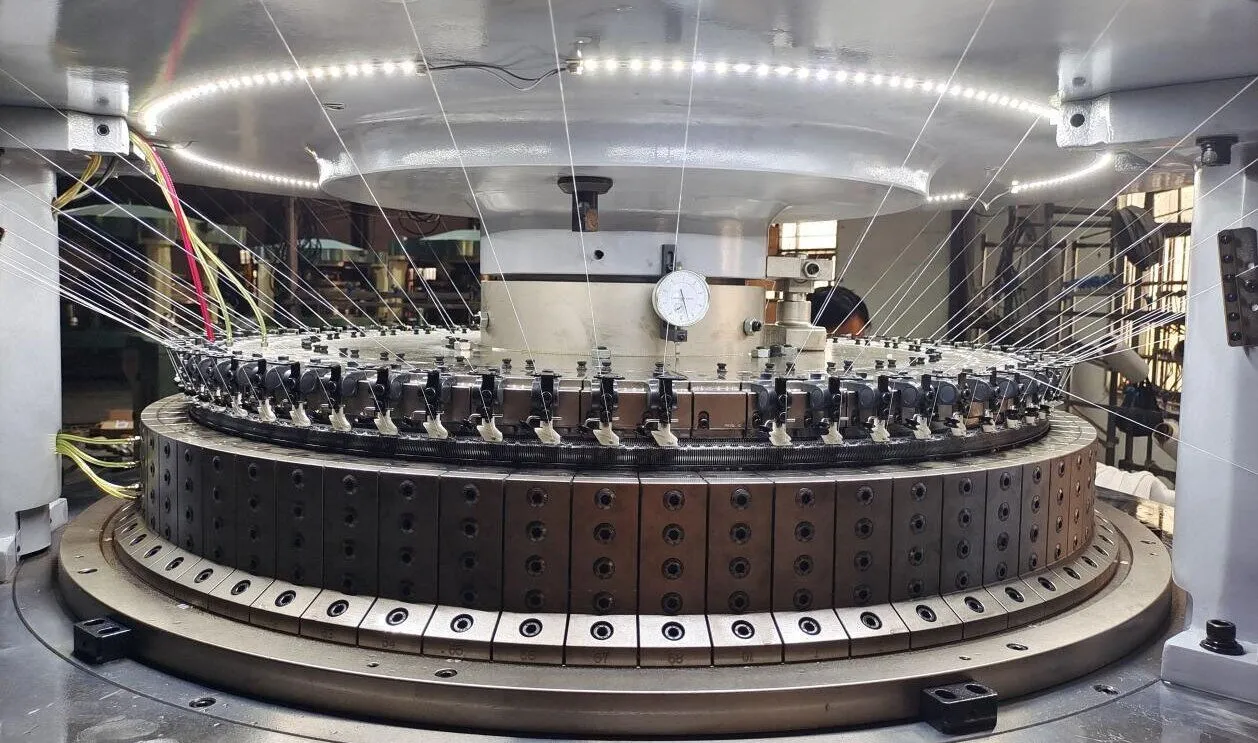

Interlock Circular Knitting Machine for the Thailand Market

Jan 20, 2025

In the textile industry, the demand for high-quality, durable, and versatile fabrics has led to the development of specialized knitting machines. One of the most essential and widely used machines for producing such fabrics is the interlock circular knitting machine. Known for its ability to produce double-sided, thick, durable, and elastic fabrics, the interlock circular knitting machine is a cornerstone in textile manufacturing, particularly for applications that require high-performance materials.

As Thailand’s textile industry continues to evolve, there is a growing need for advanced machinery to meet the demand for innovative fabrics. This article explores the capabilities of interlock circular knitting machines, their features, and their relevance to the Thai market, providing insights into how these machines can meet the needs of manufacturers in the region.

What is an Interlock Circular Knitting Machine?

An interlock circular knitting machine is a specialized type of circular knitting machine designed to produce interlock fabrics. These fabrics are characterized by their double-sided construction, which makes them thicker, more durable, and more elastic than single jersey fabrics. Interlock fabrics are commonly used in the production of a wide range of textile products, from high-performance apparel to technical fabrics and medical textiles.

Unlike regular circular knitting machines, which produce single-layer fabrics, interlock machines use two needle beds to create a unique structure that results in a fabric with two interconnected layers. This construction provides additional durability, thickness, and elasticity, making it ideal for producing fabrics used in a variety of high-demand applications.

Key Features of the Interlock Circular Knitting Machine

Interlock circular knitting machines are equipped with a range of advanced features that ensure high-quality fabric production. These features contribute to the machine’s efficiency, precision, and versatility, making it a valuable investment for textile manufacturers. Some of the most notable features include:

1. Needle Bed Configuration and Interlock Gating

Interlock circular knitting machines feature a specialized needle bed configuration that is essential for producing interlock fabrics. The needles are arranged in two separate needle beds, with each bed positioned at a precise angle to create the interlocking structure of the fabric. This configuration, known as interlock gating, ensures that only one needle bed is used at each feeder, which is critical for achieving the fabric’s distinctive double-sided structure.

2. Dual CAM System

One of the most innovative features of the interlock circular knitting machine is its dual CAM system. Each needle bed contains two independent CAM systems, which control the needles on the bed in alternating orders. The first CAM system weaves at one feeder, while the second processes at a subsequent feeder, ensuring that the interlocking fabric structure is consistent and uniform throughout the knitting process. This system also helps to prevent uneven fabric tension, resulting in a smoother, more uniform finished product.

3. Spare Needle Settings

The arrangement of the needles on interlock circular knitting machines is designed to maximize the quality of the fabric. The needles are positioned in an alternating sequence, and each needle is controlled by a separate CAM system. This diagonal, non-opposite stitch arrangement ensures that the stitches are tightly knitted, which contributes to the fabric’s unique texture and appearance. This feature also improves the machine’s efficiency by reducing the likelihood of needle breakage and misalignment.

4. Independent Yarn Feeder Adjustment

The yarn feeder on interlock circular knitting machines can be adjusted independently for each feeder. This feature allows for precise control over the yarn tension and ensures that the fabric is knitted evenly across all feeders. Additionally, an extra Lycra attachment can be installed to enable the knitting of elastic double jersey fibers, further expanding the machine’s versatility and ability to produce stretch fabrics.

5. Closed-Track CAM Design

The cams on both the lower and upper dials of the interlock circular knitting machine feature a closed-track design. This design enhances the machine’s efficiency by minimizing friction between the cam tracks and the yarn, resulting in smoother operation and reduced wear on the components. The closed-track system also helps to maintain consistent tension throughout the knitting process, improving the overall quality of the fabric.

Universal Double-Sided Interlock Circular Knitting Machine: Key Specifications

The Universal Double-Sided Interlock Circular Knitting Machine is an advanced model that offers exceptional performance, versatility, and ease of use. This machine is particularly suited for the production of various double jersey fabrics, including interlock fabrics, elastic health cloth, twill, and high-end apparel materials. Here are some of its key specifications:

Diameter: 8 – 44 Inch

Gauge: 6 – 40 Gauge

Number of Feeders: 16 to 88/106 Feeders

Available Materials: Interlock fabrics, elastic health cloth, twill, air layer, double mesh, high-class men’s or women’s apparel, and more.

Advantages of the Universal Double-Sided Interlock Circular Knitting Machine

The Universal Double-Sided Interlock Circular Knitting Machine offers several distinct advantages for textile manufacturers, particularly those targeting the growing demand for high-performance fabrics in Thailand and other Southeast Asian markets. Here are some of the key benefits:

1. Versatility in Fabric Production

The machine is highly versatile, capable of producing a wide variety of double jersey fabrics. This includes interlock fabrics, elastic health cloths, twill, and high-class apparel fabrics. This versatility makes it an ideal choice for manufacturers that need to produce a diverse range of textiles for various markets.

2. High Efficiency and Consistency

With its dual CAM system and closed-track design, the Universal Double-Sided Interlock Circular Knitting Machine operates with high efficiency and produces fabrics with consistent quality. This ensures that manufacturers can meet the growing demand for high-quality fabrics without sacrificing production speed or consistency.

3. Ease of Conversion to Rib Knitting

The machine can be easily converted to a rib knitting machine, providing additional flexibility in fabric production. This feature allows manufacturers to expand their product offerings without investing in separate machines, making it a cost-effective solution for growing businesses.

4. Optimized for Elastic Fabrics

The addition of a Lycra attachment allows the machine to knit elastic double jersey fibers, which is crucial for producing stretch fabrics. This feature is particularly beneficial for manufacturers producing apparel fabrics, including activewear and other garments that require elasticity and flexibility.

5. Dependable Performance

With its durable components and reliable design, the Universal Double-Sided Interlock Circular Knitting Machine provides dependable performance, ensuring that manufacturers can maintain consistent production without frequent downtime or maintenance.

The Thai Market: A Growing Demand for High-Quality Fabrics

Thailand is a key player in Southeast Asia’s textile and garment industry, with a strong manufacturing base and a growing demand for high-quality fabrics. The country has long been known for its textile production, and with the global shift towards sustainable and performance-driven textiles, there is an increasing demand for specialized machinery like the interlock circular knitting machine.

As the Thai textile industry focuses on expanding its capabilities and upgrading to advanced technologies, the interlock circular knitting machine is perfectly positioned to meet the need for high-performance fabrics. Manufacturers in Thailand are looking for reliable, versatile machines that can produce fabrics with superior elasticity, durability, and quality, making the Universal Double-Sided Interlock Circular Knitting Machine an ideal solution.

Conclusion: The Future of Fabric Production in Thailand

As the textile industry in Thailand continues to grow, manufacturers will need to invest in advanced machinery that can produce high-quality, versatile fabrics. The interlock circular knitting machine is a crucial piece of equipment for meeting the growing demand for durable, elastic, and double-sided fabrics. With its unique features, versatility, and efficient production capabilities, the Universal Double-Sided Interlock Circular Knitting Machine is set to play a key role in shaping the future of fabric production in Thailand and beyond.

By investing in state-of-the-art knitting machines, Thai textile manufacturers can stay ahead of global trends, improve production efficiency, and deliver high-performance fabrics that meet the ever-evolving needs of the market.

Next: Fully Automatic Single Jersey Circular Knitting Machine for the Philippines Market

Previous: Jacquard Circular Knitting Machine: Revolutionizing the Vietnam Market

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.