Interlock Circular Knitting Machine: Transforming Fabric Production in Colombia

Feb 10, 2025

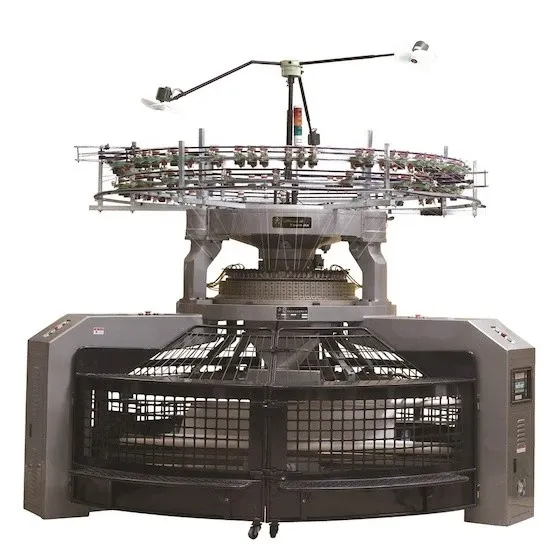

The textile industry plays a crucial role in Colombia’s economy, contributing significantly to both local and international markets. As consumer demand for high-quality fabrics continues to rise, manufacturers are looking for ways to improve their production processes, enhance efficiency, and meet the increasingly diverse needs of the global textile market. The High-Speed Interlock Open Width Circular Knitting Machine emerges as a cutting-edge solution, designed to meet these demands with unrivaled precision and flexibility.

This advanced knitting machine combines the high-quality output of interlock knitting with the unique benefits of open-width technology, offering an ideal solution for a variety of applications. Whether producing swimwear, sportswear, or technical textiles, this machine is poised to transform the Colombian textile industry by providing faster, more efficient production and improved fabric quality.

In this article, we explore the machine’s innovative features, key specifications, and its potential impact on the Colombian market. The machine's high production capacity, versatility, and user-friendly operation make it a game-changer for manufacturers striving to stay competitive in an evolving industry.

The Interlock Open Width Circular Knitting Machine represents the latest advancement in textile manufacturing. Unlike traditional circular knitting machines that produce tubular fabrics, this machine’s open-width design ensures the production of flat fabrics without the typical central crease, which is common in tubular knitted fabrics. By eliminating this crease, manufacturers can reduce cutting waste and improve the overall efficiency of the production process.

This machine is engineered to offer high-speed performance while maintaining the highest standards of fabric quality, with a variety of configurations available to meet different production needs. It is designed for the production of a wide range of fabrics, including everything from swimwear and sportswear to technical textiles, offering versatility to textile manufacturers across different market segments.

Diameter: 26 to 44 inches

Gauge: 16 to 32 gauge

Feeder Quantity: 52F to 83F feeder/inch

Available Materials: Swimwear, tights, underwear, T-shirts, polo shirts, gym suits, sportswear, technical textiles, and more.

This machine is designed to enhance productivity while maintaining the superior quality of fabric that the Colombian textile market is known for. Below are some of its standout features:

One of the most significant advantages of this machine is its open-width design, which produces flat fabric without central creases. Unlike traditional tubular fabric, which requires unfolding before use, this feature reduces cutting waste and ensures a higher-quality final product. This is particularly important for markets where fabric precision and quality are critical.

To further streamline the production process, the machine is equipped with an automatic cloth-collecting stick that rolls the fabric as it is produced. This feature makes handling and processing fabrics more efficient, especially for smaller sizes or delicate materials that need to be processed carefully.

Safety is a priority with this machine. It includes a safe shutdown function that activates in the event that the fabric has not been cut completely, ensuring that both the machine and the fabric are protected from potential damage. This enhances operational safety and minimizes downtime.

The roller speed adjustment device is crucial for maintaining uniform knitting tightness, allowing manufacturers to produce consistent, high-quality fabrics across different production runs. This feature helps to minimize defects and ensures that every batch of fabric meets the same standards.

Designed to offer the best of both double jersey machines and open-width technology, the Interlock Open Width Circular Knitting Machine is capable of producing fabrics at a high rate of speed without compromising on quality. Its ability to handle large volumes of fabric quickly makes it a valuable asset for manufacturers with high production demands.

This machine is highly versatile and can be used to produce a wide variety of fabrics, from lightweight and stretchable materials for swimwear to durable fabrics for sportswear and technical textiles. Its ability to handle different materials and gauge sizes makes it an essential tool for textile manufacturers serving diverse market niches.

The textile industry in Colombia is known for its innovation and quality, and the High-Speed Interlock Open Width Circular Knitting Machine is designed to support this reputation by enhancing the quality and efficiency of fabric production. Here are some of the key applications for the machine in the Colombian market:

As fitness and outdoor activities continue to gain popularity in Colombia, the demand for sportswear and activewear fabrics has increased. The machine’s ability to produce durable, flexible, and breathable fabrics makes it an ideal choice for the sportswear sector, where comfort, performance, and quality are paramount.

Colombia is famous for its vibrant swimwear industry, which requires fabrics that are not only lightweight and stretchable but also resistant to chlorine and saltwater. The Interlock Open Width Circular Knitting Machine’s precision and versatility ensure that manufacturers can produce high-quality swimwear fabrics that meet these demanding requirements.

The growing demand for premium, comfortable underwear and lingerie in Colombia has led to the need for soft, seamless fabrics. The machine’s ability to produce fine, seamless fabrics in various gauges makes it perfectly suited for these delicate applications. Furthermore, its high production capacity ensures that manufacturers can meet the increasing demand for these products.

Colombia’s growing industrial sector, including industries such as automotive, healthcare, and construction, requires specialized technical textiles. The machine’s ability to produce high-performance fabrics tailored to these industries opens up new opportunities for Colombian manufacturers to tap into these niche markets.

With Colombia’s burgeoning fashion industry, the demand for versatile fabrics for T-shirts, polo shirts, gym suits, and other apparel continues to rise. The machine’s versatility in producing various fabric types makes it an essential tool for manufacturers who want to stay ahead of market trends while maintaining high standards of quality.

The Interlock Open Width Circular Knitting Machine offers a range of benefits that can help Colombian textile manufacturers enhance their competitive edge:

With its high-speed capabilities and high production capacity, the machine allows manufacturers to boost output while meeting the growing demands of both domestic and international markets.

The machine’s open-width design eliminates central creases, ensuring smooth, high-quality fabrics that meet international standards. This feature is especially important in markets where fabric quality is a top priority.

By eliminating the need for cutting waste, the open-width design makes production more efficient and sustainable, reducing the overall cost of manufacturing and minimizing environmental impact.

The machine’s ability to work with a wide range of materials and applications makes it an excellent investment for textile manufacturers looking to diversify their product lines and serve various markets.

The machine’s user-friendly features, such as automatic cloth rolling and safe shutdown, ensure ease of operation and reduce the risk of operational errors, making it a highly efficient and safe choice for manufacturers.

The High-Speed Interlock Open Width Circular Knitting Machine represents a significant advancement for Colombia’s textile industry, offering a powerful solution to meet the growing demands for high-quality fabric production. With its ability to produce a wide range of fabrics efficiently and sustainably, this machine is set to drive innovation and help manufacturers remain competitive in both domestic and international markets.

As Colombia’s textile industry continues to evolve, investing in this state-of-the-art technology will enable manufacturers to increase productivity, reduce waste, and produce fabrics of superior quality. This machine not only improves production efficiency but also helps to shape the future of fabric manufacturing in Colombia, providing a smart, future-proof investment for textile businesses looking to expand their product offerings and strengthen their market position.

Next: Why Horizontal Bars Appear on Circular Knitting Machines: Causes and Solutions

Previous: Mini Polyester Fabrics Jacquard Circular Knitting Machine: Transforming Turkey’s Textile Industry

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.