Interlock Open Width Circular Knitting Machine Exported to Brazil

Feb 21, 2025

In a significant development for the textile industry, the state-of-the-art Interlock Open Width Circular Knitting Machine has been successfully exported to Brazil. This cutting-edge machinery is set to revolutionize fabric production in the region, offering unparalleled efficiency, versatility, and quality. With its advanced features and robust design, the machine is poised to meet the growing demands of Brazil’s textile sector, catering to a wide range of applications, from swimwear and sportswear to technical textiles.

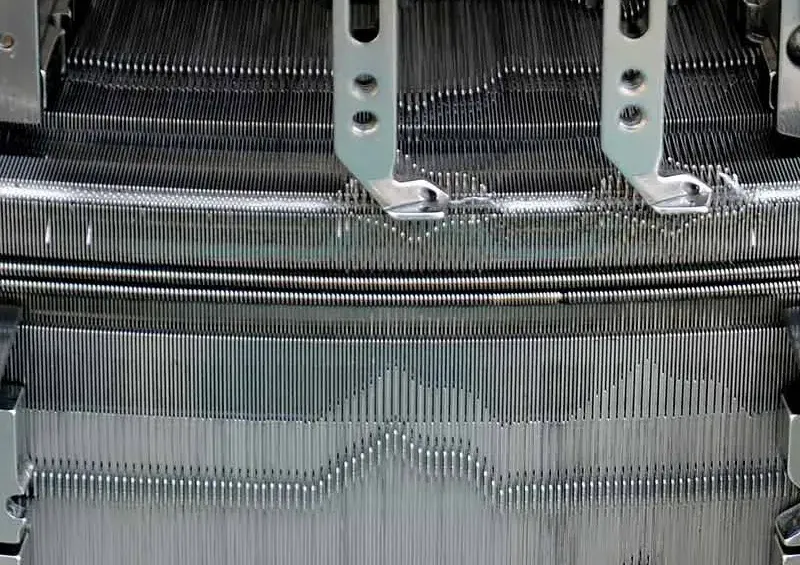

The Interlock Open Width Circular Knitting Machine is a high-performance textile manufacturing solution designed to deliver seamless, high-quality fabric production. Available in diameters ranging from 26 to 44 inches and gauges from 16 to 32, the machine is equipped with 52 to 83 feeders per inch, making it suitable for a diverse array of materials. These include swimwear, tights, underwear, T-shirts, polo shirts, gym suits, sportswear, and technical textiles. Its versatility and precision make it an ideal choice for manufacturers seeking to enhance productivity and reduce waste.

The machine is engineered with advanced energy-saving technologies, significantly reducing power consumption without compromising performance. This design not only lowers operational costs but also aligns with sustainable practices, making it an environmentally friendly choice. By optimizing energy usage, the machine ensures long-term cost-effectiveness and reliability, even under demanding working conditions.

Quality is at the core of the machine’s design and manufacturing process. Each unit undergoes a meticulous three-stage quality inspection process, where every component and functionality is scrutinized to meet the highest standards. Additionally, the machine complies with stringent industry certifications, ensuring it adheres to global benchmarks for safety, reliability, and durability. This rigorous approach guarantees that every machine delivered is built to last and perform consistently.

The machine is designed to operate with minimal noise and exceptional smoothness, creating a comfortable and productive working environment. Its advanced engineering reduces vibrations and mechanical friction, ensuring seamless functionality. This not only enhances operator comfort but also boosts efficiency, as workers can focus on their tasks without distractions or interruptions caused by noisy or erratic machinery.

To ensure the highest quality, every material used in the machine’s production is subjected to thorough testing. Detailed records of these tests are maintained, providing a comprehensive history of material performance and quality. This meticulous approach ensures consistency across all orders and allows for traceability, enabling quick identification and resolution of any potential issues.

The machine’s components are stored in an organized and systematic manner, with a dedicated stock keeper overseeing all inventory activities. Every incoming and outgoing part is meticulously logged, ensuring accurate tracking and efficient management of stock levels. This streamlined inventory system minimizes delays, prevents shortages, and ensures that production runs smoothly and on schedule.

Transparency and accountability are integral to the machine’s production process. Every stage of manufacturing is carefully documented, including the names of the workers involved in each step. This level of detail ensures full traceability, allowing for accountability at every level of production. It also provides customers with confidence in the integrity and quality of the manufacturing process.

Before any machine is delivered to the customer, it undergoes a series of rigorous tests to ensure it meets all performance and quality standards. Customers receive detailed reports, including high-resolution pictures and videos, documenting the testing process. This transparency not only builds trust but also provides customers with a clear understanding of the machine’s capabilities and condition before it reaches their facility.

The machine is supported by a highly skilled and professional technical team, composed of experts with extensive knowledge and experience in the field. This team ensures that the machine delivers exceptional performance, particularly in areas such as wear resistance and heat resistance. Their expertise guarantees that the machine is not only built to the highest standards but also optimized for long-term performance in challenging environments.

The Interlock Open Width Circular Knitting Machine features a unique gear design that eliminates the need to unfold the fabric, making it easy to roll up the cloth. It also includes a safe shutdown function that activates if the cloth is not completely cut, preventing damage and ensuring safety. The machine’s cloth-collecting stick automatically rolls up the fabric, enabling the processing of diverse sizes, including smaller pieces that are typically challenging to handle.

Additionally, the machine is equipped with a roller speed adjustment device, which ensures uniform and stable knitting tightness, resulting in consistently high-quality fabric. One of its standout features is the ability to produce premium fabric without any central crease, significantly reducing cutting waste during subsequent processing. This capability not only enhances efficiency but also contributes to sustainable manufacturing practices.

The machine combines the best features of double jersey machines with the no-fold mark characteristic of open-width machines, offering unmatched versatility. Its high production capacity makes it an ideal choice for manufacturers looking to scale their operations while maintaining superior fabric quality. Whether producing intricate designs for swimwear or durable materials for sportswear, the machine delivers exceptional results across a wide range of applications.

The export of the Interlock Open Width Circular Knitting Machine to Brazil marks a significant milestone for the country’s textile industry. Brazil, known for its vibrant fashion and textile sector, is constantly seeking innovative solutions to enhance productivity and meet global standards. This machine’s advanced features and efficiency are expected to empower local manufacturers, enabling them to compete more effectively in the international market.

The machine’s ability to produce high-quality fabric with minimal waste aligns with the growing emphasis on sustainability in the textile industry. By reducing cutting waste and optimizing resource utilization, it supports environmentally conscious manufacturing practices, which are increasingly important to both producers and consumers.

The manufacturers of the Interlock Open Width Circular Knitting Machine have adopted a customer-centric approach, ensuring that every machine meets the highest standards of quality and performance. From rigorous pre-delivery testing to comprehensive documentation, customers are provided with complete transparency and support throughout the process. The availability of a highly skilled technical team further ensures that any operational challenges are promptly addressed, minimizing downtime and maximizing productivity.

The introduction of the Interlock Open Width Circular Knitting Machine to Brazil represents a transformative moment for the country’s textile industry. With its advanced features, energy efficiency, and commitment to quality, the machine is set to redefine fabric production standards. By combining the versatility of interlock knitting with the convenience of open-width technology, it offers a seamless and efficient solution for manufacturers seeking to elevate their operations.

As Brazil continues to strengthen its position in the global textile market, the adoption of such innovative machinery will play a crucial role in driving growth, sustainability, and competitiveness. The Interlock Open Width Circular Knitting Machine is not just a tool for production; it is a catalyst for progress, empowering manufacturers to achieve new heights of excellence in the ever-evolving world of textiles.

Next: Single Terry Open Width Circular Knitting Machine for India: A Comprehensive Overview

Previous: Pure Cotton Electronic Jacquard Circular Knitting Machine Introduced to South Africa

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.