Interlock Rib Circular Knitting Machine for Uzbekistan Market

Jan 13, 2025

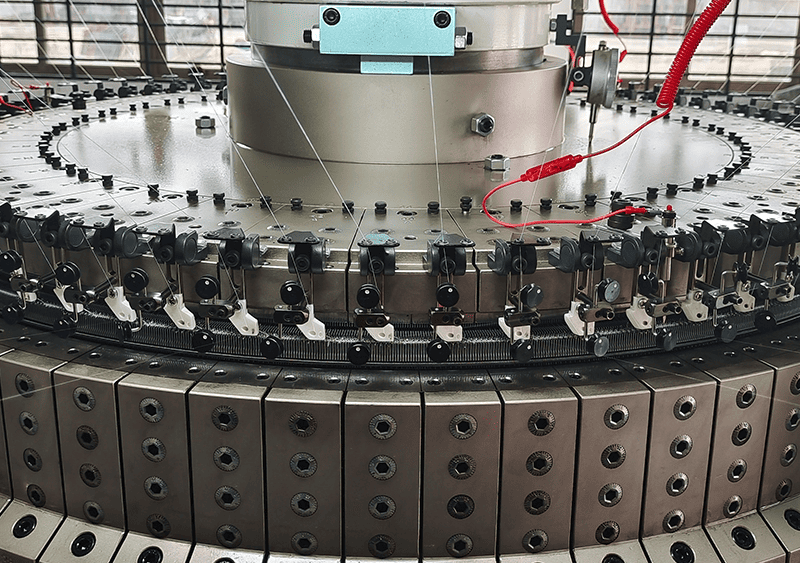

The textile industry in Uzbekistan is undergoing rapid growth, with a rising demand for high-quality, versatile fabrics used in a wide range of applications. Among the machinery playing a critical role in meeting this demand is the Interlock and Rib Double Jersey Circular Knitting Machine. This machine, renowned for its precision engineering and cutting-edge technology, offers a variety of features that make it an ideal choice for the production of top-tier interlock and rib fabrics.

The Interlock and Rib Double Jersey Circular Knitting Machine is available in a range of specifications, including diameters from 8 to 44 inches, and gauges from 6 to 40 gauge. The number of feeders ranges from 16 to 88/106, making this machine suitable for both small and large-scale production environments. This machine is designed to process a variety of fabrics, such as interlock fabrics, elastic health cloth, twill, air layer, double mesh, and high-class men's and women's apparel.

One of the key highlights of the Interlock and Rib Double Jersey Circular Knitting Machine is its advanced design. It incorporates closed-track dial cams in both the upper and lower sections of the machine, which support the knitting, tuck, and miss cams. This design ensures a high level of control over the knitting process, enabling the production of a wide range of fabrics with excellent consistency.

Additionally, the machine’s independently adjustable yarn feeder allows for fine-tuned control of the yarn feed, making it suitable for the knitting of elastic double jersey fibers. The machine also features an optional Lycra attachment, offering further versatility for applications requiring stretch or enhanced elasticity.

The versatility of this machine is further emphasized by its ability to seamlessly convert into a rib knitting machine. This interchangeability allows manufacturers to diversify their fabric offerings without needing to invest in additional specialized equipment. Whether producing interlock fabrics for apparel or rib fabrics for activewear or undergarments, the Interlock and Rib Double Jersey Circular Knitting Machine delivers high-quality results.

Interlock fabric is one of the key products produced on this machine. Interlock fabrics are highly regarded for their smooth texture, durability, and versatility in both casual and high-end fashion markets. The process of producing interlock fabric on a circular knitting machine is specialized and requires precise coordination between various machine components.

To produce interlock fabrics, the machine must incorporate the following components:

The needles in the two beds of the machine are positioned exactly opposite each other. This unique needle placement ensures that only one of the two needle beds can knit at any given time, providing the alternating knit pattern essential for interlock fabrics.

Each bed is equipped with two separate cam systems. These cam systems control half of the needles in an alternate sequence. One cam system operates at one feeder, while the other controls the next feeder. This alternating cam mechanism is critical for producing the interlock knit structure.

The needles are arranged alternately in each bed, with one needle set controlled by one cam system and the next set controlled by the other. This diagonal, non-opposing needle configuration ensures that the needles from both beds knit together efficiently, creating the distinctive interlock fabric pattern.

Traditionally, the interlock machine used needles of varying lengths: long needles would knit at one feeder, while short needles operated at the next feeder. However, in modern machines like the Interlock and Rib Double Jersey Circular Knitting Machine, needles of the same length are used, improving the efficiency and precision of the knitting process.

Interlock fabric is widely used in a variety of industries due to its superior properties. It is smooth, soft, and comfortable, making it ideal for high-quality garments such as activewear, undergarments, and high-end fashion. Furthermore, interlock fabric’s two-way stretch makes it suitable for elastic health cloths and apparel that require flexibility and comfort. It is also highly durable, providing longevity to finished products.

The Interlock and Rib Double Jersey Circular Knitting Machine offers a unique combination of flexibility and versatility, capable of producing a wide array of fabric types beyond interlock. The machine’s adaptability allows for the production of fabrics such as elastic health cloth, twill, air layer, and double mesh, all of which are in high demand across global markets, including Uzbekistan.

The machine’s adjustable feeder system and the option to add Lycra enable the production of fabrics designed for health and wellness applications. These fabrics are commonly used in compression garments, medical textiles, and athletic wear.

Twill is a durable fabric often used in workwear, outerwear, and other heavy-duty applications. The Interlock and Rib Double Jersey Circular Knitting Machine can produce twill fabrics with excellent texture and structure, meeting the demands of the global textile market.

The machine can also be used to produce air layer fabrics, which have a lightweight, breathable, and insulating quality. These fabrics are particularly popular in outerwear and activewear, where comfort and performance are paramount.

Double mesh fabrics are used in a variety of applications, from athletic gear to fashion apparel. The machine’s precision and flexibility allow for the creation of these intricate and high-performance fabrics with ease.

The Interlock and Rib Double Jersey Circular Knitting Machine is designed for high efficiency and minimal downtime, ensuring optimal productivity in textile manufacturing. The machine’s ability to produce a wide range of fabric types without the need for extensive adjustments makes it a cost-effective choice for manufacturers looking to maximize their production capabilities.

Furthermore, the machine’s easy interchangeability between interlock and rib knitting functions ensures that manufacturers can quickly switch between fabric types as demand fluctuates, thus minimizing the need for multiple specialized machines and optimizing space in the production facility.

Uzbekistan’s textile industry has experienced significant growth in recent years, and the demand for high-quality, versatile fabrics continues to rise. The Interlock and Rib Double Jersey Circular Knitting Machine plays a pivotal role in meeting this demand by offering advanced technology and superior flexibility in fabric production.

The machine’s ability to produce a diverse range of fabrics is particularly well-suited to Uzbekistan’s textile market, where there is a growing need for premium fabrics in the fashion, health, and industrial sectors. Whether producing fabrics for luxury apparel, athletic wear, or medical textiles, the machine offers the versatility, precision, and efficiency required by modern textile manufacturers.

The Interlock and Rib Double Jersey Circular Knitting Machine is a state-of-the-art solution for Uzbekistan's textile market, offering unmatched flexibility, precision, and efficiency. With its ability to produce a wide range of high-quality fabrics, including interlock, rib, elastic health cloth, and more, this machine is poised to play a significant role in driving the future of Uzbekistan’s textile industry. Its advanced features, combined with its adaptability, make it an essential tool for manufacturers looking to meet the growing demand for premium fabrics in this dynamic market.

Next: Jacquard Circular Knitting Machine: Revolutionizing the Vietnam Market

Previous: Rib Circular Knitting Machine for the Russian Market: Revolutionizing Fabric Production

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.