Optimizing Double Jersey Circular Knitting Machine Precision

Jan 06, 2024

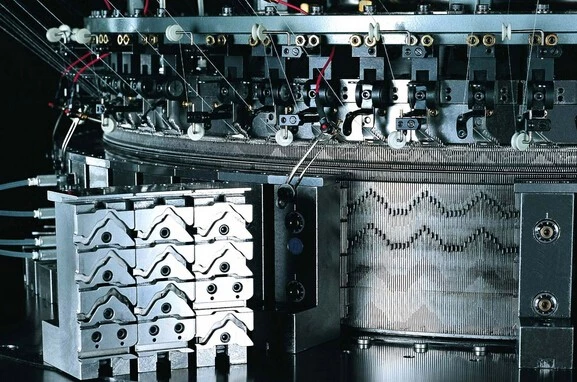

Double jersey circular knitting machines play a crucial role in textile manufacturing. However, maintaining precise circular degree and flatness is essential for optimal performance. This guide addresses common issues in double jersey circular knitting machines, such as chain wheel abrasion and flaws on the cylinder, providing methods for inspection and solutions.

Chain Wheel Abrasion

Chain wheel abrasion can lead to loosening or wearing issues.

To inspect:

1. Stop the machine and place a dial indicator on the needle plate bracket.

2. Use a gauge stand on non-operating parts to absorb any movement.

3. Push and pull the chain wheel and tray, observing the dial indicator variation.

4. If the variation is below 0.001, precision is excellent; 0.01mm-0.03mm is good, and above 0.05mm indicates poor precision.

Solution:

1. Loosen fastening screws, regulate cylinder and dial to <0.03mm.

2. Check and regulate flatness; if >0.05mm, use spacers and adjust until <0.05mm.

3. Check for flaws and record degree data; resolve oval shapes or deviations.

Cylinder Flaws

If circular degree remains >0.05mm after eliminating interference factors, analyze degree data. Differences <0.02mm between spots suggest an oval shape, while closed circular degrees with partial deviations indicate flaws.

Solution:

1. Loosen screws and regulate cylinder and dial to <0.03mm.

2. Check the flatness; if >0.05mm, use spacers and adjust until <0.05mm.

3. Loosen header after regulation, ensuring cylinder and dial remain relaxed.

3. Circular Degree Regulation:

After flatness regulation, keep the dial indicator on the cylinder, pointing to the contact surface.

1. Adjust the tray left and right; use spacers for precision.

2. Loosen located block, adjust circular degree, and focus on tray adjustment range limitations.

3. Adjust circular degree by eliminating external forces, readjust, and lock the located blocks.

Regular inspection and precise adjustments are vital for maintaining circular degree and flatness in double circular knitting machines. Addressing chain wheel abrasion, cylinder flaws, and regulating circular degree ensures optimal machine performance and longevity.

Next: Selecting the Right Cam for Your Circular Knitting Machine

Previous: Yuanda Wish You a Happy New Year!

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.