Position and Function of Settling Plate on Single Jersey Knitting Machine

Jul 29, 2024

In modern knitting technology, the settling plate an important part of knitting machine, its unique design and structure not only ensure the smooth formation and closure of the coil, but also affect the quality and production efficiency of the fabric. In this paper, the motion principle, design characteristics and the importance of settling plate in the knitting process of single jersey circular knitting machine are discussed in depth, and theoretical support and practical suggestions are provided for professionals in the knitting industry.

What is a Settling Plate

Settling plate is one of the main "loop forming parts" of knitting machine. Made of thin steel sheets. The settler plate and the knitting needle are arranged alternately, the two are configured at nearly 90°, and the settling arc or extension line of the "coil" is regularly held, and the knitting needle is formed into a circle. According to the process requirements, the settler can be made into various shapes.

Position and Function of Settling Plate on Single Jersey Knitting Machine

The movement of the settling plate of the single jersey circular knitting machine is controlled by its triangular configuration, while the settling plate is used as an auxiliary device to create and close coils during the weaving process. When the shuttle is opening or closing the coil, the jaws of the sinker act like the two side walls of the needle slots on a double-sided knitting machine, blocking the yarn, causing the shuttle to form a coil, and pushing the old coil away from the mouth of the shuttle as it completes the coil.

To prevent the old coil from getting stuck at the top of the shuttle as the needle rises and retract, the sinker's jaws must use their sharp teeth to push the old coil away from the fabric surface and maintain a grip on the old coil as the shuttle rises and retract to ensure that the coil is completely removed. Therefore, the position of the settling plate claw significantly affects the technical position of the settling plate in the weaving process, and then affects the weaving process.

From the settler plate's role in the weaving process, the jaws of the settler plate should push the old coil away from the top of the needle before the shuttle rises and retracts its coil. As far as the distance from the yarn to the knitting machine is concerned, as long as the warp is placed behind the needle, the phenomenon of the new thread passing through or puncturing the old thread as the needle rises can be avoided. If pushed too far, the fall of the new net will be blocked by the jaw of the settling plate, resulting in a smooth weaving process.

Theory and Practical Operation of Settling Plate

In theory, when the jaws of the settling plate move up and down during the weaving cycle, they should only touch the back line of the needle as it rises, allowing for a smooth descent. Any further advance will disturb the settling arc of the new coil, thus affecting the weaving process. However, in practice, it is not enough to select the position of the settling CAM to contact the needle and thread of the settling plate jaw. Many factors affect the choice of its location.

The most common is a single-sided knitting machine settling plate with a bend, and if the pin line is used as the reference for installing the sinking Cam, then the jaws of the settling Cam should always be aligned with the pin line throughout the process, running along curve 4a, from the time the braiding needles finish coil formation and begin unwinding until they reach their highest point and finish unwinding. From a microscopic point of view, it can be seen that the actual sag arc of the new coil always exceeds the back line of the needle in the mouth of the tiger, resulting in the sag arc of the new coil always in a state of stress during the weaving process.

Microscopic Analysis

When weaving fine fabrics, the influence of large diameter coils is not obvious. However, when weaving heavy fabrics, due to the small diameter of the coil, it is easy to appear defects such as holes. Therefore, the drafting Cam technique for selecting this type of curve cannot be based on the matching of the jaws and needles. In the actual installation, it should be slightly removed from the position of the tiger mouth and the needle and thread.

If the adjustment ruler is aligned with the needle back line at point T, the ruler should remain in place until the shuttle begins to rise from the coil formation to reach its highest point. During this process, the mouth of the measuring stick should be located outside the back line of the needle except when the shuttle begins to rise. At this point, even if the point of the drooping arc of the new coil is stressed instantaneously, it will not significantly affect the weaving process, because the forces between the coils will transfer to each other. Therefore, the location of the trapezoid plate in and out of the selection should be based on the alignment of the trapezoid plate with the back line of the needle when adjusting in the workshop.

The Relationship Between Settling Plate and Yarn

From the microeconomic point of view, the shape of the jaws of the settling plate is a semi-circular net arc, one end of which overlaps with the claw. As shown in Figure 2, during the weaving process, the yarn forms a curve on the claw. Before the shuttle completes its coil and begins to rise to the claw level, if the settling plate is pushed down to line up with the needle, the descending arc of the new coil is not at the deepest point of the settling plate, but on the curved surface between the settling plate and the claw, as shown in Figure 3. This point is far away from the needle and, unless the crack shape is rectangular, the fall of the new coil is forced here.

Settling Plate Cam Installation

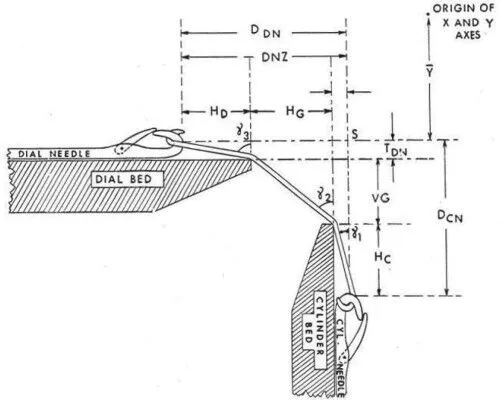

At present, the most common single-sided knitting machine settling plate curve Cam on the market can be roughly divided into two types, as shown in Figure 4. In Figure 4a, the dashed line is an arc that passes through the Cam S on the settling plate, the center of which coincides with the center of the needle. If the pin line is used as the basis for mounting the settler Cam, the claws of the settler should always be aligned with the pin line throughout the process, from the time the braiding needle completes its weft line to the exit coil, until the highest point is reached and the coil is completed. From a microscopic point of view, it can be seen that the actual sag arc of the new coil always exceeds the back line of the needle in the mouth of the tiger, resulting in the sag arc of the new coil always stressed during the weaving process.

When weaving delicate fabrics, the effect is not obvious due to the large coil length. However, when weaving heavy fabrics, due to the small length of the coil, it is easy to appear defects such as holes. Therefore, the selection of this curved sewing pattern cannot be based on the alignment of the tiger's mouth with the needle and thread. When installing, align the needle slightly outward on the back line of the tiger's mouth.

Adjustment of Shuttle During Ascent

If the slot is aligned with the back line of the needle, the slot should be located outside the back line of the needle from the beginning of the knitting needle unwinding the weft line until it reaches its highest point, except at the point T where it coincides with the back line of the needle when the knitting needle begins to rise. During this period, even if the point of the drooping arc of the new coil is stressed instantaneously, the weaving process is not significantly affected due to the mutual transfer of forces between the coils. Therefore, the selection of the location of the sinker Cam in and out should be based on the alignment of the sinker Cam with the needle when adjusting in the workshop.

A change in machine number means a change in needle pitch, which is reflected in the fabric as a change in the sag arc of the weft. The longer the settling arc length, the higher the machine number; On the contrary, the shorter the subsidence arc length, the lower the machine number. With the increase of machine number, the allowable thread density of weaving is reduced, the yarn strength is lower, and the length is shorter. Even small forces can change the shape of a coil, especially when weaving polyurethane fabrics.

Ending

To sum up, the sinker is indispensable in the operation of the knitting machine, and its design and adjustment are directly related to the loop quality and weaving efficiency of the fabric. Understanding the motion mechanism of settling plate and its interaction with knitting needles and yarns is of great significance for optimizing weaving process and improving product quality.

Next: Why Use an Interlock Circular Knitting Machine?

Previous: Solutions to Reduce Fabric Holes in Interlock Circular Knitting Machines

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.