Pure Cotton Electronic Jacquard Circular Knitting Machine Introduced to South Africa

Feb 17, 2025

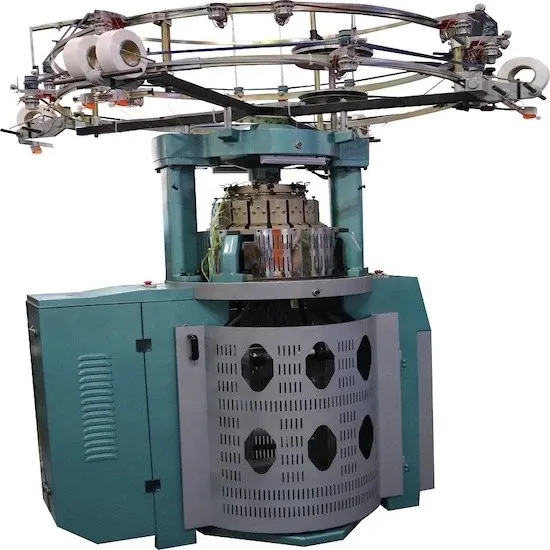

The textile industry in South Africa is poised for a significant transformation with the introduction of the Small Diameter Electronic Jacquard Circular Knitting Machine. This state-of-the-art machine is designed to meet the growing demand for high-quality, intricately designed fabrics in the region. With its advanced features and versatile capabilities, the machine is set to revolutionize fabric production, offering manufacturers a competitive edge in both local and international markets.

The Small Diameter Electronic Jacquard Circular Knitting Machine is engineered to handle a wide range of materials, including pure cotton, chemical fabric mixed fabric, silk, and artificial wool. Its compact design, combined with electronic jacquard capabilities, makes it an ideal choice for producing intricate patterns and designs with precision and efficiency. This article delves into the features, benefits, and potential impact of this innovative machine on South Africa’s textile industry.

The Small Diameter Electronic Jacquard Circular Knitting Machine is a cutting-edge solution designed for precision knitting tasks. It is available in diameters ranging from 6 to 12 inches and offers a gauge range of 6 to 20 gauge, making it suitable for a variety of fabric types and thicknesses. The machine is equipped with 12 to 24 feeders, allowing for high-speed production and versatility in fabric design.

Key Specifications:

Diameter: 6 to 12 inches

Gauge: 6 to 20 gauge

Feeder Quantity: 12 to 24 feeders

Compatible Materials: Pure cotton, chemical fabric mixed fabric, silk, and artificial wool

One of the standout features of this machine is its ability to produce double jacquard fabrics with exceptional precision. The innovative structure of the machine ensures that even the most complex patterns and designs are executed flawlessly. This capability is particularly valuable for manufacturers looking to create high-end fabrics for fashion, home textiles, and technical applications.

The double jacquard functionality allows for the creation of intricate designs on both sides of the fabric, opening up new possibilities for creative expression and product differentiation. Whether it’s geometric patterns, floral motifs, or custom designs, the machine delivers top-tier results that meet the highest industry standards.

The Small Diameter Electronic Jacquard Circular Knitting Machine is designed to maximize productivity and profitability. It features 2 feeders per inch and is powered by a high-speed motor, enabling it to produce fabrics at an impressive rate. This high-speed operation ensures that manufacturers can meet tight deadlines and large order volumes without compromising on quality.

The combination of speed and precision makes the machine an invaluable asset for businesses looking to scale their operations and increase their market share. By reducing production time and minimizing waste, the machine helps manufacturers achieve greater efficiency and cost-effectiveness.

Ease of use is a key consideration in the design of this machine. It is equipped with an electronic control panel, yarn adjusting disc, and electronic inverter, which together provide effortless control and adjustment capabilities. The intuitive interface allows operators to easily configure the machine for different fabric types, patterns, and production requirements.

The electronic control panel also enables real-time monitoring of the production process, ensuring that any issues can be quickly identified and addressed. This user-friendly design reduces the learning curve for operators and minimizes the risk of errors, resulting in consistent, high-quality output.

Despite its advanced capabilities, the Small Diameter Electronic Jacquard Circular Knitting Machine boasts a compact design that makes it suitable for a wide range of production environments. Its small footprint allows it to be installed in facilities with limited space, while its versatility ensures that it can handle a variety of materials and fabric types.

The machine’s adaptability makes it an ideal choice for manufacturers producing everything from lightweight, breathable fabrics for clothing to durable, textured materials for home textiles. Its ability to switch between different materials and patterns with ease further enhances its appeal to businesses with diverse product lines.

The introduction of the Small Diameter Electronic Jacquard Circular Knitting Machine is expected to significantly enhance South Africa’s textile manufacturing capabilities. By enabling the production of high-quality, intricately designed fabrics locally, the machine reduces the need for imports and supports the growth of the domestic textile industry.

This shift toward local production not only strengthens the economy but also creates job opportunities and fosters skill development within the sector. As more manufacturers adopt this advanced technology, South Africa is likely to emerge as a key player in the global textile market.

With increasing consumer awareness of environmental issues, there is a growing demand for sustainable and eco-friendly fabrics. The Small Diameter Electronic Jacquard Circular Knitting Machine is well-suited to meet this demand, as it can efficiently process pure cotton and other natural fibers.

By producing fabrics from sustainable materials, manufacturers can cater to environmentally conscious consumers and align with global trends toward sustainability. This positions South African textile businesses to compete more effectively in international markets, where eco-friendly products are increasingly prioritized.

The advanced features of the Small Diameter Electronic Jacquard Circular Knitting Machine enable South African manufacturers to produce fabrics that meet international quality standards. This enhances their competitiveness in the global market and opens up new export opportunities.

The ability to create intricate, high-quality designs at a competitive cost gives South African textile businesses a distinct advantage. By leveraging this technology, they can attract international buyers and establish themselves as reliable suppliers of premium fabrics.

The compact design and user-friendly operation of the machine make it accessible to small and medium enterprises (SMEs) in the textile sector. SMEs often face challenges in accessing advanced technology due to cost and space constraints. However, the Small Diameter Electronic Jacquard Circular Knitting Machine offers an affordable and practical solution that enables these businesses to compete with larger manufacturers.

By empowering SMEs with cutting-edge technology, the machine contributes to the diversification and resilience of South Africa’s textile industry. It also encourages innovation and entrepreneurship, driving further growth and development in the sector.

The introduction of the Small Diameter Electronic Jacquard Circular Knitting Machine marks a significant milestone for South Africa’s textile industry. With its advanced features, including double jacquard production, high-speed operation, and user-friendly controls, the machine is set to revolutionize fabric production in the region.

By enhancing local manufacturing capabilities, meeting the demand for sustainable fabrics, and boosting competitiveness in the global market, this innovative machine offers numerous benefits for South African textile businesses. Its compact and versatile design also makes it accessible to SMEs, fostering inclusivity and growth within the sector.

As South Africa continues to position itself as a hub for textile innovation, the Small Diameter Electronic Jacquard Circular Knitting Machine is poised to play a pivotal role in shaping the future of the industry. By embracing this technology, manufacturers can unlock new opportunities, drive economic growth, and contribute to the sustainable development of the textile sector.

Next: Interlock Open Width Circular Knitting Machine Exported to Brazil

Previous: Why Horizontal Bars Appear on Circular Knitting Machines: Causes and Solutions

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.