Single Terry Open Width Circular Knitting Machine for India: A Comprehensive Overview

Feb 25, 2025

The textile industry is one of India’s most vital sectors, providing significant contributions to employment, economic growth, and export revenues. Over the years, India’s textile market has grown exponentially, driven by a rising demand for high-quality fabrics and the evolution of modern manufacturing technologies. Among the many innovations that have revolutionized textile production, the Single Terry Open Width Circular Knitting Machine stands out. Known for its versatility, high efficiency, and ability to produce a wide variety of knitted fabrics, this machine is a game-changer for manufacturers seeking to meet market demands while improving operational performance. This article explores the key features, specifications, and benefits of this cutting-edge machine, emphasizing its importance in the rapidly expanding Indian textile market.

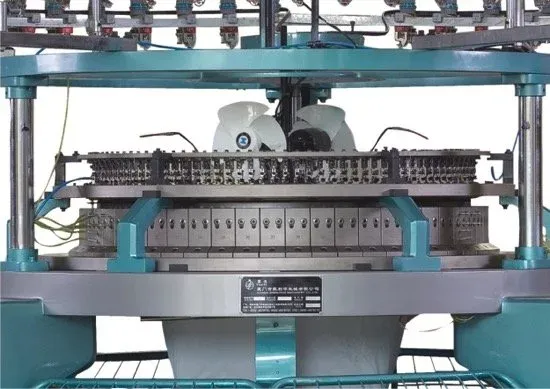

The Single Terry Open Width Circular Knitting Machine is a state-of-the-art equipment designed to cater to the diverse needs of the modern textile industry. Capable of producing fabrics from a range of materials, it offers manufacturers an efficient solution to meet the growing demand for high-quality knitted fabrics. Its ability to handle different fabric types and designs makes it an indispensable tool for textile manufacturers looking to stay competitive and innovative.

Diameter: Available in diameters ranging from 6 to 44 inches, providing flexibility for different production requirements.

Gauge: The machine is available in gauges from 14 to 44, enabling manufacturers to create fabrics of varying textures and densities.

Number of Feeders:

18F to 132F (3 feeders/inch)

24F to 176F (4 feeders/inch)

Materials Supported: This machine can handle a wide array of materials, including pure cotton, chemical fiber, mixed fiber, silk, and artificial wool, making it highly versatile and adaptable to different fabric types.

One of the standout features of the Single Terry Open Width Circular Knitting Machine is its 4-track cams seal design. This design includes knit cams, tuck cams, and miss cams, which provide precise control over the knitting process. The ability to adjust these cams ensures that manufacturers can produce a wide range of fabric patterns and textures with excellent consistency. This versatility is crucial for adapting to the varying demands of the textile market.

The machine is equipped with a high-precision central raising and falling system. This system facilitates easy and rapid adjustments to the fabric weight, enabling manufacturers to produce fabrics of different thicknesses and densities. This feature is particularly beneficial for producing fabrics that require fine-tuned characteristics, such as softness, stretchability, and durability.

The feeding yarn carrier is designed to optimize the efficiency of Lycra utilization. This innovation ensures that the yarn is fed smoothly and consistently during the knitting process, reducing wastage and improving overall fabric quality. The precise control over yarn feeding contributes to the production of high-quality knitted fabrics with uniformity in texture and strength.

The ergonomic design of the Single Terry Open Width Circular Knitting Machine enhances operator safety and comfort. The machine features an additional middle feeding yarn transfer ring, which improves the ease of monitoring and handling the yarn during the knitting process. Additionally, the design prevents direct contact between the machine and the operator’s body, ensuring a safer working environment that reduces the risk of injuries.

The yarn carrying system is engineered for smooth and stable performance, allowing the machine to operate at high speeds without compromising fabric quality. This feature is essential for maintaining efficiency in high-volume production while ensuring that the final product meets the desired standards of durability and aesthetics.

A key benefit of the Single Terry Open Width Circular Knitting Machine is its versatility. The machine can be easily converted into different types of knitting machines, such as 3-thread fleece and terry machines, by simply swapping out core components. This adaptability allows manufacturers to produce a wide variety of fabrics, including basic fabrics, textured knits, and complex patterns. The ability to switch between different fabric types without the need for additional machinery helps manufacturers save on capital investment and operational costs.

With its advanced technology and high-speed operation, the Single Terry Open Width Circular Knitting Machine significantly boosts production efficiency. Manufacturers can produce large volumes of fabric in a shorter period, helping them meet the rising demand for knitted fabrics in India. This efficiency is crucial in a highly competitive market where speed to market is essential for success.

The machine’s ability to handle multiple fabric types from a range of materials makes it a cost-effective solution for manufacturers. Rather than investing in several specialized machines, manufacturers can use the Single Terry Open Width Circular Knitting Machine to produce various fabrics with ease. This reduces capital expenditure, minimizes maintenance costs, and optimizes operational efficiency, ultimately leading to lower production costs.

Precision is critical in textile manufacturing, and the Single Terry Open Width Circular Knitting Machine excels in this area. The machine’s advanced design ensures that fabric quality is maintained at the highest standards, with consistent texture, uniformity, and strength. By producing high-quality fabrics, manufacturers can maintain a competitive edge in the market and cater to customers looking for premium textile products.

The textile market in India is highly dynamic, with manufacturers constantly required to produce different fabric types to meet consumer preferences. The flexibility of the Single Terry Open Width Circular Knitting Machine makes it an ideal solution for this ever-changing market. By allowing easy conversion between various fabric types, the machine enables manufacturers to quickly adapt to shifts in consumer demand, reducing downtime and boosting production capacity.

The ergonomic design of the machine ensures that operators can work safely and comfortably, which is crucial for maintaining productivity in a high-demand environment. Features such as the middle feeding yarn transfer ring reduce the risk of accidents, while the machine’s layout ensures that operators can easily monitor the knitting process. This focus on operator safety and comfort contributes to a more productive and sustainable work environment.

The Single Terry Open Width Circular Knitting Machine represents a significant advancement in textile manufacturing, offering unmatched versatility, efficiency, and precision. For the Indian textile industry, which is experiencing rapid growth in demand for high-quality knitted fabrics, this machine provides an invaluable tool for manufacturers seeking to stay competitive. With its advanced features, such as the 4-track cams seal design, high-precision central raising system, and versatile functions, this machine ensures the production of high-quality fabrics at a cost-effective rate.

In addition to improving production efficiency and fabric quality, the machine’s ergonomic design enhances operator safety and comfort, contributing to a better overall working environment. By offering flexibility and adaptability, the Single Terry Open Width Circular Knitting Machine empowers manufacturers to cater to diverse market needs, all while reducing operational costs and capital investment.

In conclusion, investing in the Single Terry Open Width Circular Knitting Machine is a strategic decision for textile manufacturers in India. It allows businesses to enhance their production capabilities, meet evolving market demands, and position themselves for long-term success in an increasingly competitive textile landscape.

Next: Factory-Price Jacquard Circular Knitting Machines Exported to Peru

Previous: Interlock Open Width Circular Knitting Machine Exported to Brazil

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.