Single Terry Velour Circular Knitting Machine for Sudan Market

Mar 03, 2025

The textile industry in Sudan is poised for a significant transformation with the introduction of the Single Terry Velour Circular Knitting Machine. This state-of-the-art machine is designed to meet the growing demand for high-quality, luxurious fabrics in the region. With its advanced features, versatility, and ability to handle a wide range of materials, this machine is set to revolutionize fabric production in Sudan. Whether you're producing velour, terry, or other knitted fabrics, this machine offers unmatched precision, efficiency, and adaptability, making it an ideal choice for textile manufacturers looking to elevate their production capabilities.

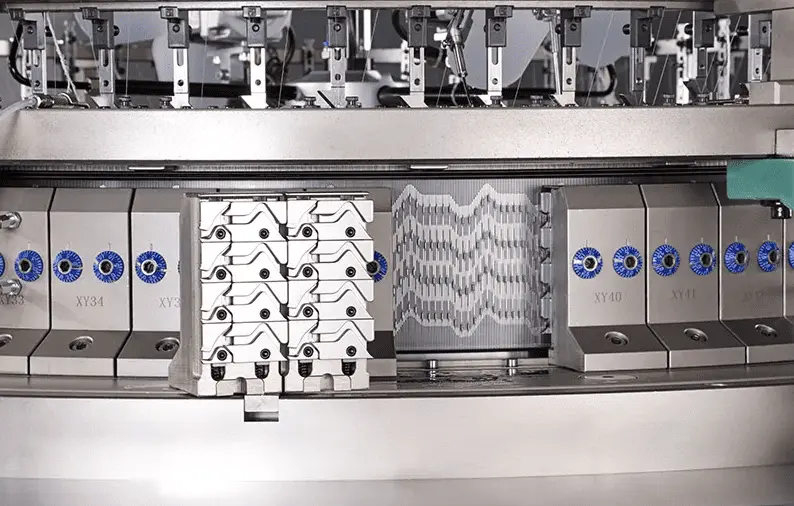

The Single Terry Velour Circular Knitting Machine is a cutting-edge piece of equipment designed for high-performance fabric production. It is available in a variety of configurations to suit different production needs, with diameters ranging from 6 to 44 inches and gauges from 14 to 44. The machine offers flexibility in feeder quantities, with options for 18F to 132F (3 feeders/inch) and 24F to 176F (4 feeders/inch), ensuring it can handle both small-scale and large-scale production requirements.

One of the standout features of this machine is its ability to work with a wide range of materials, including:

Pure cotton

Chemical fibers

Mixed fibers

Silk

Artificial wool

This versatility allows manufacturers to produce a diverse array of fabrics, from lightweight and breathable materials to heavy-duty and luxurious textiles, catering to various market demands.

The Single Terry Velour Circular Knitting Machine is packed with innovative features that set it apart from traditional knitting machines. These features ensure superior fabric quality, operational efficiency, and ease of use.

The machine adopts a 4-track cams seal design, which includes knit cams, tuck cams, and miss cams. This design allows for precise control over the knitting process, enabling the production of complex fabric patterns with ease. The high-precision central raising and falling system further enhances this capability, allowing operators to adjust fabric weight quickly and conveniently.

The machine features a special feeding yarn carrier design that makes the incorporation of Lycra and other elastic materials more proficient. This design ensures smooth and consistent yarn feeding, reducing the risk of yarn breakage and improving overall fabric quality.

The machine is designed with operator comfort in mind. The additional middle feeding yarn transfer ring allows personnel to monitor and carry yarn without the machine touching their bodies. This ergonomic design not only enhances operator safety but also ensures that the yarn carrying system is freer and steadier, enabling high-speed knitting without compromising on quality.

One of the most significant advantages of this machine is its multipurpose functionality. By replacing the heart parts, the machine can be easily converted into a 3-thread-fleece machine, a terry machine, or other types of knitting machines. This adaptability makes it a cost-effective investment for manufacturers looking to diversify their product offerings without purchasing multiple machines.

The Single Terry Velour Circular Knitting Machine is engineered for high-speed operation, ensuring maximum productivity without sacrificing fabric quality. Its robust construction and advanced yarn feeding system allow it to maintain consistent performance even at high speeds, making it ideal for large-scale production.

The introduction of the Single Terry Velour Circular Knitting Machine in Sudan comes at a time when the textile industry in the region is experiencing significant growth. The machine's versatility and advanced features make it well-suited for a variety of applications, including:

Velour fabrics are known for their softness, durability, and luxurious feel, making them highly sought after in the fashion and home textiles industries. With this machine, Sudanese manufacturers can produce high-quality velour fabrics that meet international standards, opening up new opportunities for export.

Terry fabrics, commonly used in towels, bathrobes, and other absorbent textiles, are another key application for this machine. Its ability to produce dense, plush terry fabrics makes it an excellent choice for manufacturers looking to cater to the growing demand for premium home textiles.

The machine's ability to work with a wide range of materials and its multipurpose functionality allow manufacturers to produce a variety of fabrics, from lightweight jerseys to heavy-duty fleece. This versatility enables businesses to adapt to changing market trends and customer preferences.

By adopting advanced knitting technology, Sudanese textile manufacturers can enhance their competitiveness in both domestic and international markets. The Single Terry Velour Circular Knitting Machine not only improves production efficiency but also ensures consistent fabric quality, helping businesses build a strong reputation for excellence.

The Single Terry Velour Circular Knitting Machine offers numerous benefits for textile manufacturers in Sudan, including:

The machine's high-speed performance and advanced features enable manufacturers to increase their production output without compromising on quality. This translates to higher profitability and a stronger competitive edge.

With its multipurpose functionality, the machine eliminates the need for multiple specialized machines, reducing capital investment and operational costs. This makes it an attractive option for both established manufacturers and new entrants in the textile industry.

The machine's precision engineering and advanced yarn feeding system ensure consistent fabric quality, reducing waste and enhancing customer satisfaction. This is particularly important for manufacturers looking to export their products to international markets.

The machine's ergonomic design prioritizes operator comfort and safety, reducing the risk of workplace injuries and improving overall productivity. This is a significant advantage in a labor-intensive industry like textiles.

By enabling the production of high-quality, durable fabrics, the machine supports sustainable manufacturing practices. Additionally, its ability to work with a variety of materials, including eco-friendly options, aligns with global trends toward sustainability in the textile industry.

The Single Terry Velour Circular Knitting Machine is a game-changer for the textile industry in Sudan. Its advanced features, versatility, and high-speed performance make it an ideal choice for manufacturers looking to elevate their production capabilities and meet the growing demand for high-quality fabrics. Whether you're producing velour, terry, or other knitted textiles, this machine offers unmatched precision, efficiency, and adaptability.

By investing in this cutting-edge technology, Sudanese textile manufacturers can enhance their competitiveness, boost production efficiency, and tap into new market opportunities. The Single Terry Velour Circular Knitting Machine is not just a piece of equipment—it's a catalyst for growth and innovation in the textile industry. As Sudan continues to develop its manufacturing sector, this machine will play a pivotal role in shaping the future of textile production in the region.

Elevate your fabric production with the Single Terry Velour Circular Knitting Machine and take your business to new heights of success. The future of textile manufacturing in Sudan starts here.

Next: The 3 Thread Fleece Fabric Circular Knitting Machine for the Bolivia Market

Previous: Factory-Price Jacquard Circular Knitting Machines Exported to Peru

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.