The Trade-offs Between Production Volume, Performance, and Quality in Knitting Machinery

Nov 15, 2023

The blind pursuit of high production volume often leads to Circular Knitting machines with limited performance and poor adaptability, accompanied by a decline in product quality and an increased risk of defective fabric. In the event of market shifts, such Circular Knitting machines can only be dealt with at lower prices.

Why is it that production volume, performance, and quality are often challenging to balance? We know that there are two main ways to increase production volume: faster rotation speed and more guide bars. Increasing the number of guide bars seems like an easier solution.

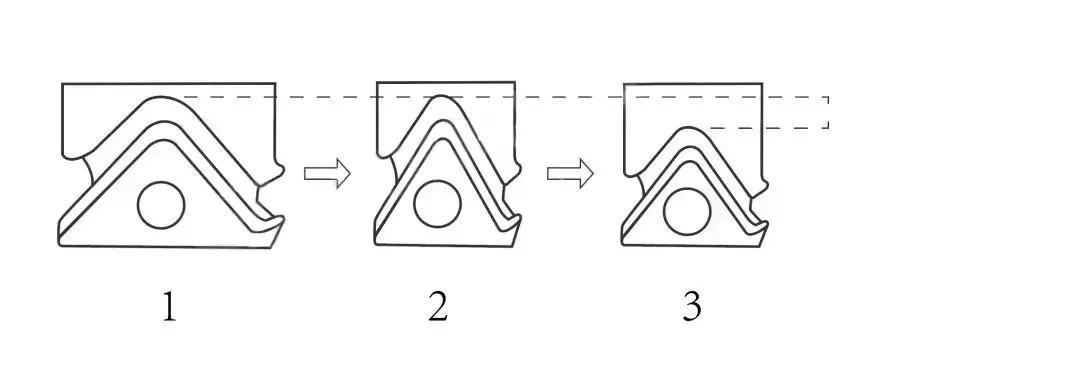

However, what happens when the number of guide bars is increased? As shown in the diagram:

After increasing the number of guide bars, the width of the triangle decreases, and the curve becomes steeper (2). A too steep curve can cause significant wear on the needle, so the height of the curve must be reduced to make it smoother (3).

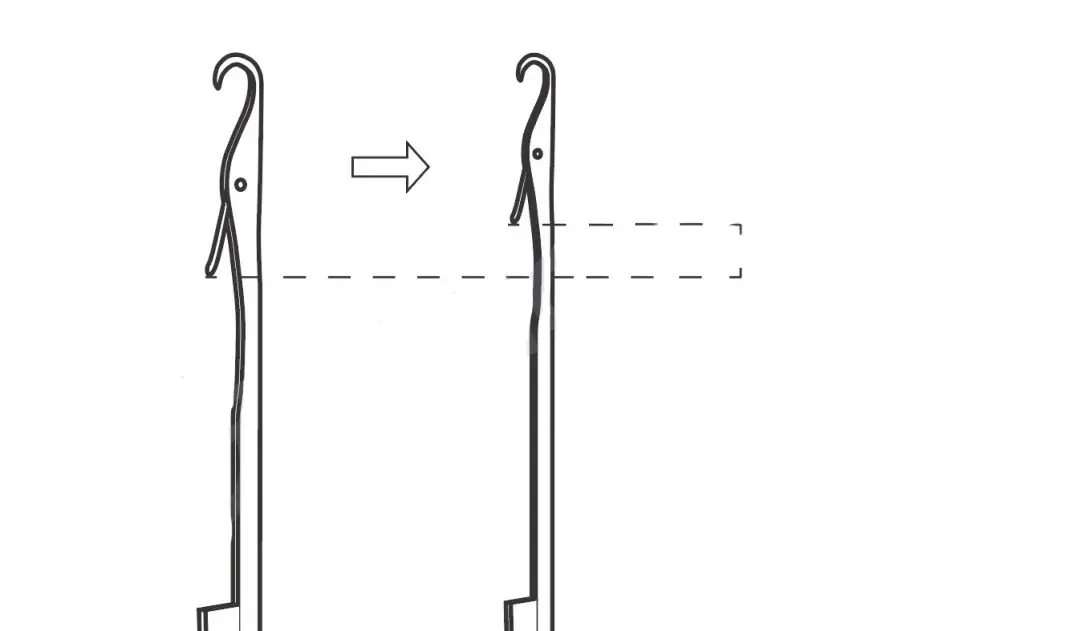

However, after reducing the curve, the height of the sinker loop decreases, and long sinker loop stitches cannot fully drop off, forcing the machine to use short sinker loop needles.

Even with the reduced space, the commonly used sinker loop needle lengths are limited to three: 8mm, 7mm, and 6mm. Therefore, the slope of the curve on high-guide-bar machines remains relatively steep, implying faster wear on the needle.

Short sinker loop needles become more challenging to operate when producing cotton yarn or adding spandex.

Due to the narrower slope of the curve, the movement space of the yarn carrier is smaller, making it more difficult to adjust the timing of the machine. These factors contribute to the limited application and adaptability of high-guide-bar machines.

High guide bar count does not necessarily lead to high profits.

The higher the guide bar count, the greater the resistance and power consumption of the machine. Everyone understands the law of energy conservation.

The higher the guide bar count, the more times the sinker loop opens and closes in one revolution of the machine, and the faster the frequency. This shortens the lifespan of the knitting needles and puts a significant strain on their quality.

With a higher frequency of sinker loop movement, the probability of introducing instability into the fabric surface increases, posing higher risks.

For example, a 96-guide-bar machine has 96 sinker loop open-close cycles in one revolution, rotating 15 times per minute. The total open-close cycles in 24 hours are 961560*24=2,073,600.

A 158-guide-bar machine, under the same conditions, has 1581560*24=3,412,800 cycles.

Therefore, the usage time of knitting needles is significantly reduced.

Similarly, the resistance and friction force on the sinker and needle bed are higher, leading to faster overall wear and tear.

In this situation, if processing fees are calculated based on time or revolutions, there must be a corresponding multiple of fees to offset these losses. In reality, unless it's an extremely urgent order, processing fees often cannot reach the same multiple as the guide bar count.

Looking at the current market situation, the outsourcing of low-end product processing is accelerating. A strategy based on price competition and high production volume is not a sustainable solution. The future for knitting enterprises with long-term development in China will undoubtedly revolve around core competitiveness in terms of quality and development capabilities.

True pursuit of high production should come from higher machine precision and more rational design. Machines should operate more efficiently, with stable and reliable performance, minimizing wear and friction to extend the knitting needle's lifespan. This leads to better fabric quality and reduces unnecessary losses.

Correspondingly, manufacturers should aim for stability, greater adaptability, broader comprehensive performance, and stronger research and development capabilities. Only such manufacturers can adapt to the market for the long term, meet your development needs, and grow together with you.

Therefore, do not blindly pursue high-guide-bar machines, as the results often lead to more losses than gains.

Next: Maintenance and Adjustment of Circular Knitting Machine

Previous: Basic Structure and Characteristics of Weft Knitting

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.