Types of Knit Fabrics from Circular Knitting Machines

Nov 15, 2024

On this page

Knitted fabrics are a fundamental part of the textile industry, used in everything from casual wear to technical apparel. The process of knitting involves creating loops of yarn, and depending on how these loops are formed, different types of knitted fabrics are produced. Circular knitting machines, in particular, are essential in the mass production of various types of knitted fabrics. These machines knit fabric in a continuous tubular form, making them ideal for creating garments like T-shirts, socks, and hosiery. Below, we’ll explore the different types of knitted fabrics and the technologies used to create them, focusing on weft and warp knitting techniques.

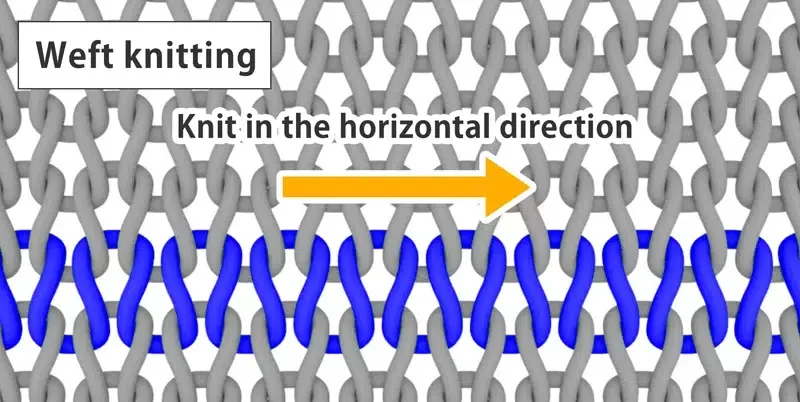

Weft knitting involves the horizontal looping of yarns across the fabric. This method produces fabrics that are highly stretchable and comfortable, making them ideal for garments that require flexibility. Weft knitting machines, especially circular knitting machines, are widely used to produce a variety of weft-knit fabrics.

One of the key features of single jersey knit fabric is its lightweight nature, making it breathable and comfortable for warm-weather wear. It also has a natural stretch, although it is less stretchy unless blended with elastane or spandex fibers. This blend allows the fabric to achieve greater elasticity, which is especially important for garments like activewear, shapewear, and leggings. Single jersey fabrics are also known for their ability to recover well after being stretched, maintaining their shape over time. Lightweight: Ideal for comfortable, breathable garments.

Stretchability: Limited stretch unless blended with elastane or spandex.

Visible Right and Wrong Sides: Single jersey fabric has distinct sides, with the "right" side being smooth and the "wrong" side being more textured.

Edge Curling: The edges of single jersey fabrics tend to curl up easily when stretched.

One of the key features of single jersey knit fabric is its lightweight nature, making it breathable and comfortable for warm-weather wear. It also has a natural stretch, although it is less stretchy unless blended with elastane or spandex fibers. This blend allows the fabric to achieve greater elasticity, which is especially important for garments like activewear, shapewear, and leggings. Single jersey fabrics are also known for their ability to recover well after being stretched, maintaining their shape over time. Lightweight: Ideal for comfortable, breathable garments.

Stretchability: Limited stretch unless blended with elastane or spandex.

Visible Right and Wrong Sides: Single jersey fabric has distinct sides, with the "right" side being smooth and the "wrong" side being more textured.

Edge Curling: The edges of single jersey fabrics tend to curl up easily when stretched.

Rib-knit fabric, also known as double jersey, is a more complex form of weft knitting. It is created by alternating knit and purl stitches, which gives it a ribbed appearance. This type of fabric is often knitted with two sets of needles, producing a fabric that is thicker, more durable, and more stable than single jersey.

Rib-knit fabrics are often used for applications that require extra elasticity, such as cuffs, collars, waistbands, and other areas where a snug fit is needed. The upright cord-like structure of rib-knit fabric provides more stretchability and better dimensional stability. This makes rib knits a popular choice for sportswear and casual wear, particularly in garments like sweaters, dresses, and cardigans.

Rib-knit fabrics are often used for applications that require extra elasticity, such as cuffs, collars, waistbands, and other areas where a snug fit is needed. The upright cord-like structure of rib-knit fabric provides more stretchability and better dimensional stability. This makes rib knits a popular choice for sportswear and casual wear, particularly in garments like sweaters, dresses, and cardigans.

Thicker Texture: Rib-knit fabrics are typically thicker than single jersey fabrics due to the knit-purl stitch pattern.

Increased Stability: Rib-knit fabrics are more stable and less prone to distortion.

Elasticity: Rib-knit fabrics provide a high level of stretch, making them ideal for form-fitting garments.

Distinct Ribbed Appearance: The alternating knit and purl stitches create a ribbed or corded appearance, which adds texture to the fabric.

Increased Stability: Rib-knit fabrics are more stable and less prone to distortion.

Elasticity: Rib-knit fabrics provide a high level of stretch, making them ideal for form-fitting garments.

Distinct Ribbed Appearance: The alternating knit and purl stitches create a ribbed or corded appearance, which adds texture to the fabric.

Interlock knit fabric is another form of double-layered knit fabric, but it differs from rib-knit fabric in that both sides of the fabric appear similar. This is achieved by alternating knit and purl stitches on both sides of the fabric using two sets of needles. Interlock knit is generally thicker and more stable than single jersey but softer and smoother than rib-knit fabrics.

Interlock fabric is commonly used for items that require durability and comfort, such as high-quality T-shirts, activewear, and children's clothing. It has excellent stretchability and can maintain its shape and softness over time, making it a popular choice for both everyday wear and technical apparel.

Interlock fabric is commonly used for items that require durability and comfort, such as high-quality T-shirts, activewear, and children's clothing. It has excellent stretchability and can maintain its shape and softness over time, making it a popular choice for both everyday wear and technical apparel.

Double Layered: The interlock knit structure creates a smooth and uniform appearance on both sides of the fabric.

Higher Stability: More stable than single jersey, with a reduced tendency to stretch out of shape.

Softness and Comfort: Interlock fabric is known for its softness, making it ideal for garments worn directly against the skin.

Durability: The tighter structure of interlock knit fabrics adds to their durability, making them suitable for items requiring high wear resistance.

Higher Stability: More stable than single jersey, with a reduced tendency to stretch out of shape.

Softness and Comfort: Interlock fabric is known for its softness, making it ideal for garments worn directly against the skin.

Durability: The tighter structure of interlock knit fabrics adds to their durability, making them suitable for items requiring high wear resistance.

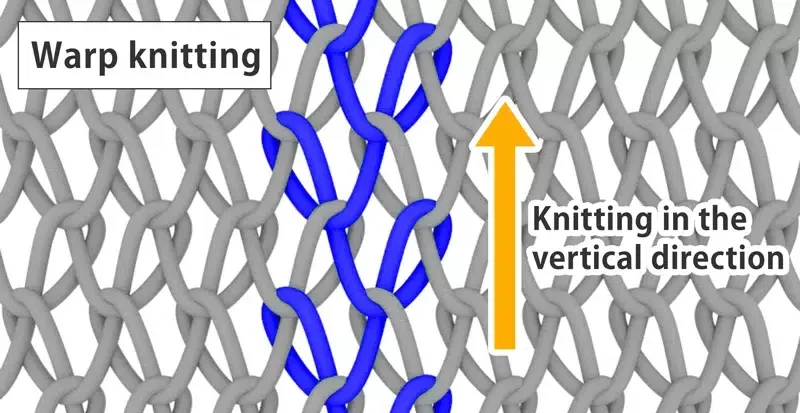

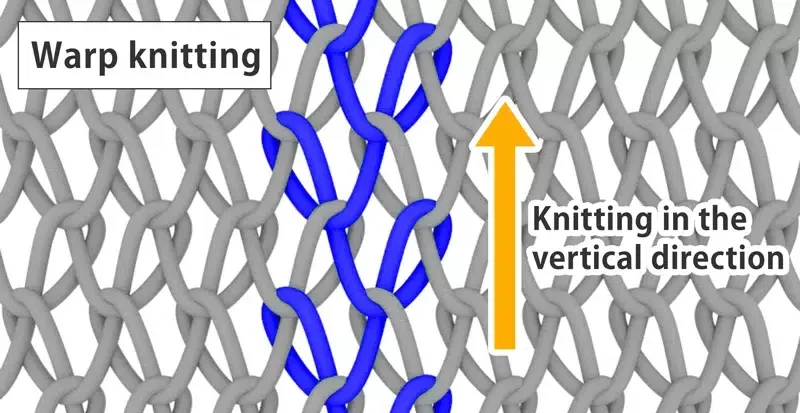

Warp knitting is another method of knitting that involves the vertical looping of yarns, as opposed to the horizontal loops found in weft knitting. Warp-knitted fabrics are typically produced on specialized machines, like the tricot and Raschel knitting machines, which can create more complex and intricate designs. Warp-knitted fabrics tend to be less stretchy than weft-knitted fabrics, but they are often more stable and durable, making them suitable for a wide range of applications, including lingerie, sportswear, and technical fabrics.

Tricot knit fabric is a type of warp-knit fabric that is produced using a single set of beard needles. Tricot fabrics are known for their smooth texture and durability. The fabric is typically made from synthetic fibers such as polyester, nylon, or spandex, which give it excellent stretch and moisture-wicking properties. Tricot is commonly used in applications like lingerie, swimwear, sportswear, and activewear, where comfort and performance are essential.

Smooth Surface: Tricot fabrics have a smooth, lustrous finish, making them visually appealing.

Stretch and Durability: Due to its warp-knit structure, tricot fabric offers excellent stretch and retains its shape even after extended use.

Lightweight: Tricot fabrics are often lightweight, making them comfortable and breathable for close-fitting garments.

Stretch and Durability: Due to its warp-knit structure, tricot fabric offers excellent stretch and retains its shape even after extended use.

Lightweight: Tricot fabrics are often lightweight, making them comfortable and breathable for close-fitting garments.

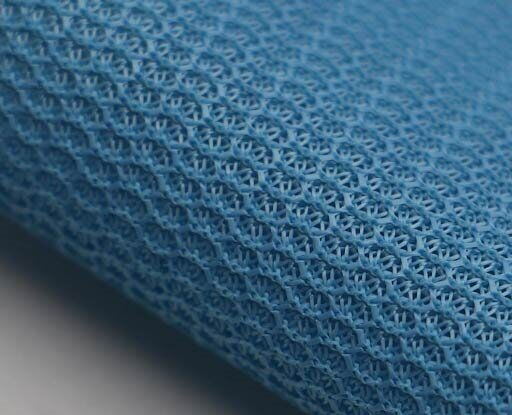

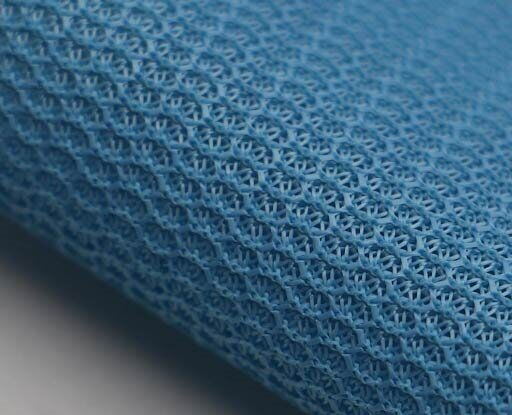

Raschel knit fabrics are produced on a Raschel knitting machine, which allows for the creation of intricate patterns, including lace, open mesh, and textured designs. Raschel knits are often used in the production of fabrics for outerwear, curtains, and fashion items that require unique visual appeal. These fabrics can be made from a variety of fibers, including nylon, polyester, and cotton, and they often feature complex textures and patterns that set them apart from simpler knitted fabrics.

Intricate Patterns: Raschel knit fabrics can be designed with lace-like patterns, making them suitable for decorative uses.

Light and Breathable: Many Raschel knits are lightweight and breathable, making them perfect for outerwear and summer clothing.

Durable: Despite their often delicate appearance, Raschel knits can be surprisingly durable, making them suitable for a wide range of applications.

Light and Breathable: Many Raschel knits are lightweight and breathable, making them perfect for outerwear and summer clothing.

Durable: Despite their often delicate appearance, Raschel knits can be surprisingly durable, making them suitable for a wide range of applications.

Milanese knit is another specialized form of warp knitting, characterized by its dense, tightly woven structure. Milanese knit fabric is used in applications that require a strong, durable fabric with a smooth finish. It is often used in making technical fabrics for outdoor gear, heavy-duty garments, and other products that require extra resilience.

Dense and Strong: The tightly woven structure of Milanese knit fabric gives it high durability.

Smooth Finish: Despite its strength, Milanese knit fabric has a smooth and clean finish.

Versatile: It is suitable for a range of applications, particularly in outdoor and technical wear.

Smooth Finish: Despite its strength, Milanese knit fabric has a smooth and clean finish.

Versatile: It is suitable for a range of applications, particularly in outdoor and technical wear.

Circular knitting machines are essential tools in the production of a wide range of knitted fabrics. From basic single jersey to intricate Raschel and Milanese knits, these machines offer versatile solutions for creating fabrics that are used in everything from everyday clothing to high-performance gear. Understanding the different types of knitted fabrics and their unique characteristics helps manufacturers choose the right material for their products, ensuring comfort, durability, and aesthetic appeal. As technology advances, the variety of knitted fabrics continues to grow, expanding the possibilities for designers and consumers alike.

Next: Recycled Nylon: A Sustainable Solution for the Future

Previous: Circular Knitting Needle Lengths: Choosing the Right Size for Your Project

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links