What Is a Jacquard Knitting Machine?

Nov 25, 2024

Let’s explore the features, benefits, and working mechanisms of jacquard knitting machines and understand why they are such a valuable asset in modern garment production.

With computerized controls, they can replicate detailed patterns with incredible accuracy.

Designers can create and store multiple designs, enabling quick pattern recall for various projects.

Faster production speeds reduce manual labor, enhancing productivity for large-scale operations.

Automated processes streamline production, minimizing errors and wastage.

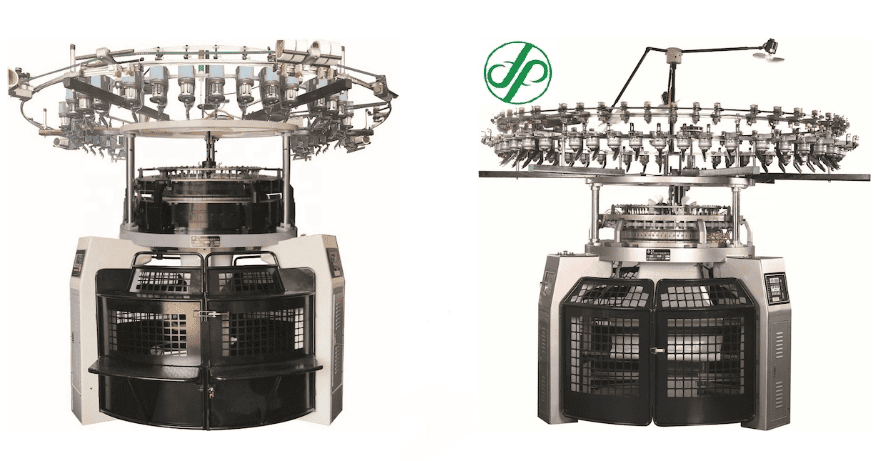

These features make jacquard knitting machines the preferred choice for industries ranging from fashion to sportswear, where customization and quality are paramount. Among the various types of jacquard knitting machines, circular jacquard knitting machines are particularly notable for their seamless and continuous production capabilities. These machines are designed to produce tubular fabrics, which are ideal for garments like socks, hats, and seamless apparel.These machines create tubular fabric without seams, eliminating the need for additional stitching and reducing material waste.

Their ability to operate continuously results in faster production times and higher output.

They can produce fabrics in different weights and textures, catering to diverse knitwear requirements.

By avoiding seams and excess fabric, circular jacquard knitting machines minimize material wastage, making them an eco-friendly option.

This combination of efficiency and versatility has made circular jacquard knitting machines a staple in industries focusing on comfort and functionality, such as underwear and sportswear manufacturing. The magic of jacquard knitting lies in the integration of advanced technology and meticulous craftsmanship. These machines utilize a digital design process to translate intricate patterns onto fabric with unmatched precision.The Working Process: Designers create patterns using specialized software, which are then uploaded to the knitting machine. This digital input guides the machine in crafting the fabric. The machine uses a network of needles to knit the fabric seamlessly. This eliminates the need for traditional stitching or seaming, resulting in a smooth and comfortable finish. Thanks to computerized programming, the machine can produce even the most complex patterns accurately and consistently, ensuring each garment meets exacting standards. The ability to store and recall designs allows manufacturers to switch between projects effortlessly, enhancing productivity and meeting diverse client demands. Jacquard knitting machines are particularly renowned for their role in producing seamless garments. These items, which include underwear, activewear, and compression wear, benefit greatly from the machines’ ability to eliminate irritating seams and provide a perfect fit. The absence of seams ensures a smoother feel against the skin, reducing chafing and irritation. Seamless construction allows for stretchable, body-hugging designs that move effortlessly with the wearer. Intricate designs can be woven directly into the fabric, adding aesthetic appeal without compromising functionality. The continuous knitting process results in stronger, longer-lasting garments.

Seamless production is especially valuable in industries like sportswear, where performance and comfort are critical. The impact of jacquard knitting machines extends beyond garment production. Their ability to combine artistry with automation has transformed textile manufacturing, opening new possibilities for innovation and creativity.

Emerging Innovations:

AI Integration: Artificial intelligence could enhance design capabilities, making the creation of intricate patterns even more intuitive.Eco-Friendly Materials: Jacquard machines are being adapted to work with biodegradable and recycled yarns, supporting sustainable fashion.

Customization on Demand: Advanced software may enable real-time customization for personalized garments, meeting the growing demand for unique products. Jacquard knitting machines have redefined the textile industry by offering precision, efficiency, and versatility. From seamless garment production to complex pattern creation, these machines have become an essential tool for modern manufacturers.

With their ability to enhance comfort, reduce material waste, and streamline production, jacquard knitting machines are not just a technological marvel—they are a game-changer for designers, manufacturers, and consumers alike. As the industry continues to innovate, the role of jacquard knitting machines will only grow, driving the future of textiles to new heights.

Next: A Comprehensive Guide to Double Jersey Circular Knitting Machines

Previous: Open-Width Single Jersey Circular Knitting Machine: Enhancing Fabric Production

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.