Why Horizontal Bars Appear on Circular Knitting Machines: Causes and Solutions

Feb 14, 2025

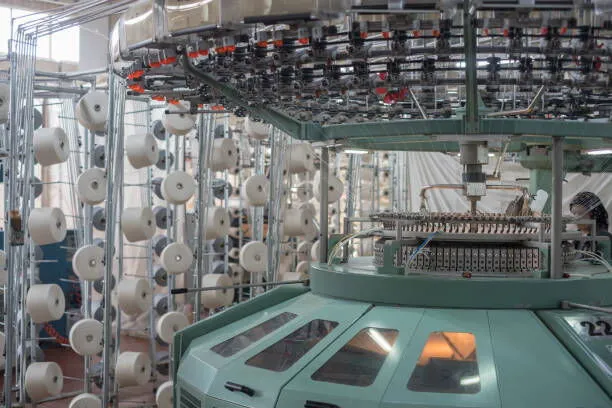

Circular knitting machines are essential tools in the textile industry, enabling the production of seamless fabrics, hosiery, and other knitted products. However, like any complex machinery, they are prone to operational issues that can affect the quality of the finished product. One common problem faced by operators is the appearance of horizontal bars or stripes on the fabric. These imperfections can compromise the aesthetic and functional quality of the knitted material. This article explores the primary causes of horizontal bars on circular knitting machines and provides practical solutions to address these issues.

Cause:

Uneven yarn tension is one of the primary reasons horizontal bars appear on circular knitted fabrics. This issue can stem from several factors, including incorrect tension settings, yarn jamming, or even uneven yarn feeding. When the yarn tension is inconsistent, it causes uneven stitching, which becomes visible as horizontal stripes across the fabric.

Solution:

To combat uneven yarn tension, operators must ensure that the tension is set properly and remains consistent throughout the knitting process. Routine inspection and maintenance of the tensioning devices and guides are crucial for this. Additionally, it is important to verify that the yarn feeds evenly from the creel or cone, as irregular yarn supply can exacerbate the tension issues. By making these adjustments, the operator can minimize the risk of horizontal bars caused by inconsistent yarn tension.

Cause:

The needle plate plays a crucial role in guiding the needles as they work in tandem with the yarn to create the knitted fabric. Over time, wear and tear can lead to damage, which disrupts the smooth operation of the needles. When the needle plate becomes worn or damaged, it can result in uneven needle movement, which is a primary cause of horizontal bars.

Solution:

Regular inspection and monitoring of the needle plate are essential to prevent these issues. Operators should check for any signs of damage or excessive wear, particularly at points where the needles make contact with the plate. If significant wear is identified, the needle plate should be replaced immediately to avoid further disruptions in production. Establishing a preventive maintenance schedule that includes checking the condition of the needle plate will ensure continued high-quality production and reduce unexpected downtime.

Cause:

The needle bed holds the needles in position, allowing them to move correctly during the knitting process. Prolonged use or improper handling can lead to failure or misalignment of the needle bed. If the needles are not properly aligned or if some are damaged or bent, they may not move in sync, leading to fabric irregularities, including horizontal stripes.

Solution:

Routine inspection of the needle bed should be part of the operator’s maintenance routine. Ensure that all needles are intact, properly aligned, and free from any damage. Any defective or bent needles should be replaced immediately. Proper needle bed alignment is crucial to maintaining consistent fabric quality. If any misalignments are found, corrective action should be taken promptly to prevent horizontal bars from appearing on the finished fabric.

Cause:

Incorrect machine settings, such as the wrong speed, tension, or tightness, can lead to horizontal bars in the fabric. Excessive speed or tension can place unnecessary strain on the yarn and needles, causing irregularities in the knitting process.

Solution:

Machine operators must pay close attention to the settings and adjust them according to the manufacturer’s recommendations. Each machine has specific parameters that should be followed for optimal performance. Over time, small adjustments may be necessary to maintain the machine’s functionality. Regularly monitoring and fine-tuning machine parameters will help prevent issues such as horizontal bars, ensuring smooth operation and high-quality results.

Cause:

Yarn clogging occurs when the yarn gets caught or knotted in the machine, disrupting its smooth flow. This can happen due to debris, improper yarn handling, or insufficient machine cleaning. When yarn flow is interrupted, it can lead to uneven fabric, including visible horizontal bars.

Solution:

To prevent yarn clogging, operators must ensure that the machine is regularly cleaned, particularly the yarn pathways. The yarn should be free from knots, tangles, or other defects before being fed into the machine. Additionally, it is essential to establish a routine maintenance schedule that includes cleaning the yarn pathways and ensuring smooth yarn flow, which will greatly reduce the risk of yarn clogging and the appearance of horizontal bars.

Cause:

The quality of the yarn itself can significantly affect the final product. Poor-quality yarn, which may have inconsistencies in thickness, strength, or texture, can lead to fabric defects, including horizontal bars. Variations in yarn quality may be subtle but can have a noticeable impact on the uniformity of the knitted fabric.

Solution:

Using high-quality yarn is essential for achieving a flawless finish. Operators should thoroughly inspect the yarn before use, checking for any defects, inconsistencies, or irregularities in thickness or strength. It is also beneficial to work with trusted yarn suppliers who maintain high-quality standards. By ensuring that the yarn meets the required specifications, operators can minimize the risk of horizontal bars appearing in the knitted fabric.

While addressing the root causes of horizontal bars is essential, operators can further minimize the occurrence of these defects by implementing best practices throughout the production process. These measures include:

Implementing a preventive maintenance schedule helps ensure that all machine components are functioning optimally, preventing the onset of issues that may lead to horizontal bars.

Ensuring that machine operators are well-trained in handling and adjusting machine parameters is critical for identifying potential problems early and addressing them before they impact production quality.

Establishing a robust quality control process allows operators to identify and rectify fabric defects early in the production process, reducing the risk of horizontal bars

Maintaining a clean, dust-free environment is essential to prevent debris or contaminants from affecting machine performance and fabric quality.

Horizontal bars on circular knitting machines are a common challenge that can impact fabric quality and production efficiency. However, with a thorough understanding of the root causes—such as uneven yarn tension, damaged machine components, improper adjustments, and yarn quality issues—operators can implement proactive solutions to address these challenges. By adhering to regular maintenance schedules, using high-quality materials, and ensuring that machine settings are correctly calibrated, textile manufacturers can significantly reduce the likelihood of fabric defects and enhance overall productivity.

By addressing these issues, the textile industry can continue to meet the growing demand for high-quality knitted products across a range of applications, from fashion garments to technical textiles. With the right preventive measures in place, manufacturers can not only improve their operations but also maintain a competitive edge in an increasingly demanding market.

Next: Pure Cotton Electronic Jacquard Circular Knitting Machine Introduced to South Africa

Previous: Interlock Circular Knitting Machine: Transforming Fabric Production in Colombia

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.