Yarn Supply Structure of Circular Knitting Machine

Nov 11, 2023

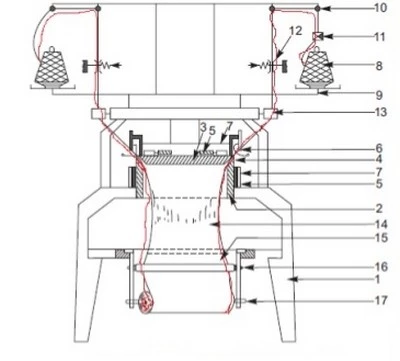

The circular knitting machine comprises a frame, yarn supply system, transmission system, lubrication and dust removal system, electrical control system, drawing and winding system, and other auxiliary devices.

Frame: The frame consists of three legs (commonly known as lower feet) and a circular (or square) tabletop. The lower feet are fixed with forks, and the tabletop (commonly known as the large plate) has three columns (commonly known as upper feet or straight feet). Safety doors (also known as protection doors) are installed in the gaps between the three lower feet, ensuring stability and safety. Noteworthy features include the internal structure of the lower feet for storing wires and tools, enhancing machine safety and cleanliness. The safety door functions reliably, automatically stopping the machine and displaying a warning on the control panel when opened to prevent accidents.

Yarn Supply Structure: The yarn supply structure, also known as the yarn feeding mechanism, includes components like the yarn rack, yarn accumulator, yarn feeder nozzle, yarn feeding disc, and yarn ring holder.

-

Yarn Rack: The yarn rack holds the yarn and comes in two types: umbrella tube rack (or top tube rack) and floor tube rack. The umbrella yarn rack occupies less space but lacks space for spare yarn, suitable for small local enterprises. The floor tube rack includes the triangular tube rack and the wall-mounted tube rack (also known as the two-piece tube rack). The triangular yarn rack is more convenient to move, and the operator can easily thread the yarn. The wall yarn rack is neat and aesthetically pleasing but occupies more space, making it suitable for larger factories.

-

Yarn Accumulator: The yarn accumulator, available in normal, elastic (for spandex and other fiber interweaving), and electronic gap yarn accumulator forms, plays a crucial role in regulating yarn tension. Yarn feeding methods include positive feeding (wrapping 10-20 turns on the accumulator), semi-negative feeding (wrapping 1-2 turns on the accumulator), and negative feeding (no wrapping on the accumulator).

-

Yarn Feeder Nozzle: Also known as the steel shuttle or yarn guide, the yarn feeder nozzle directs the yarn directly into the knitting needles. Various types and shapes include single-hole yarn feeder nozzles and double-hole single-slot yarn feeder nozzles.

-

Others: Components like the sand table control yarn feeding, and the yarn support can hold the large ring with the yarn storage device.

-

Basic Requirements for Yarn Supply Mechanism:

- Ensure uniform and continuous yarn feeding to achieve consistent loop size and shape for a smooth and aesthetically pleasing knitted product.

- Maintain reasonable yarn tension to reduce fabric defects such as missed stitches and ensure fabric quality.

- Adhere to the required yarn supply ratio between knitting systems, facilitating the adjustment of yarn supply for different colors and varieties.

- Ensure smooth and burr-free yarn hooks to prevent yarn breakage.

In summary, the yarn supply mechanism is essential for achieving quality and efficiency in circular knitting machines. Careful consideration of its components and functions is crucial for optimal machine performance and fabric production.

Next: Maintenance of Circular Knitting Machines

Previous: Circular Knitting Machine: Causes and Elimination of Stoppage Marks

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.