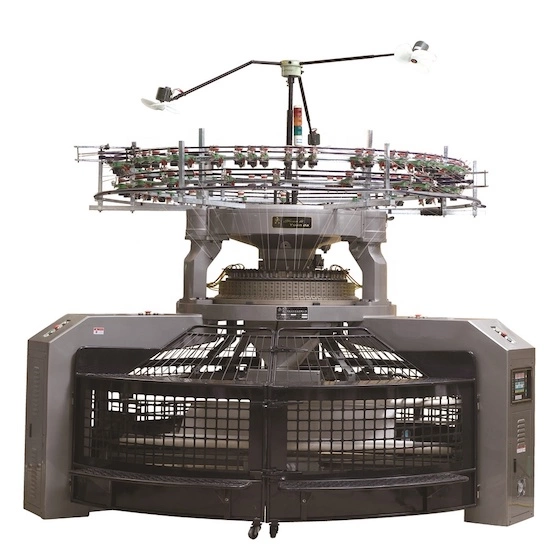

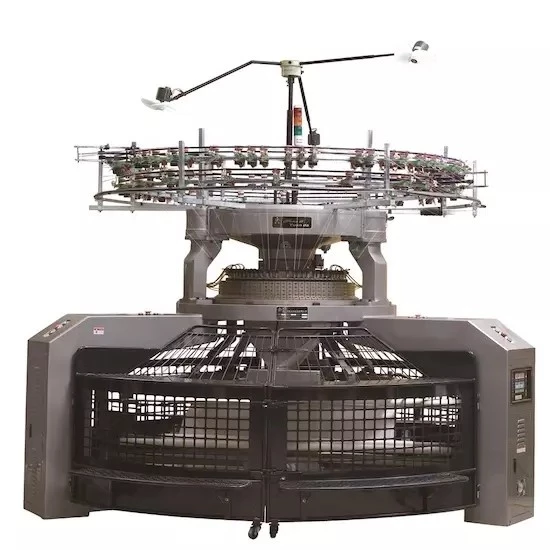

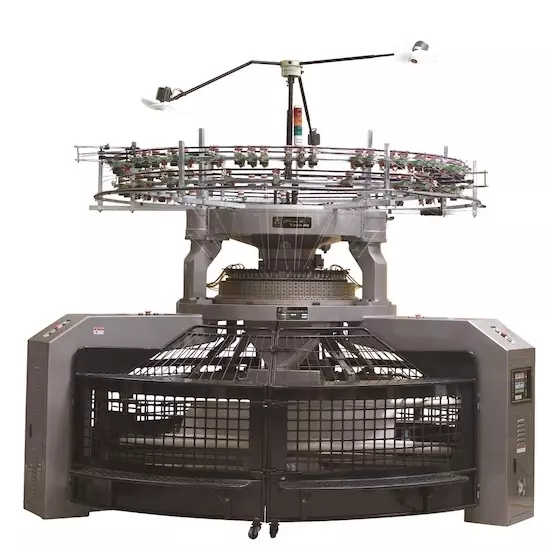

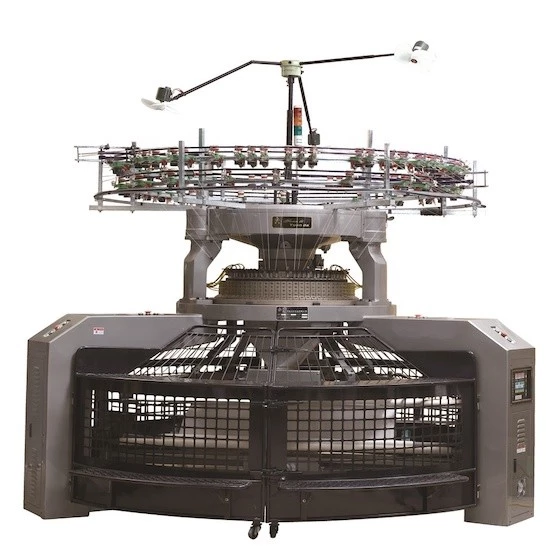

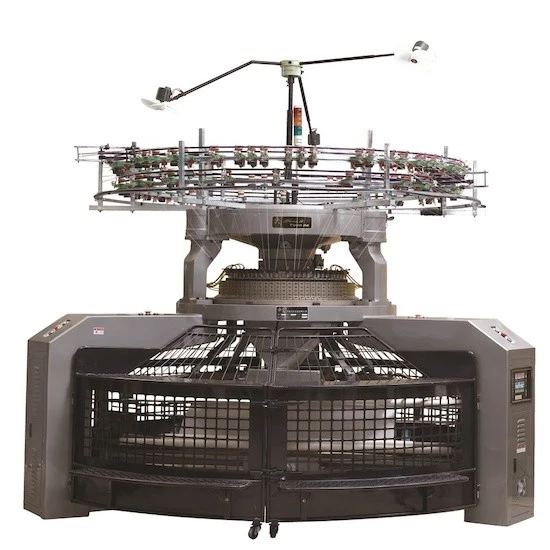

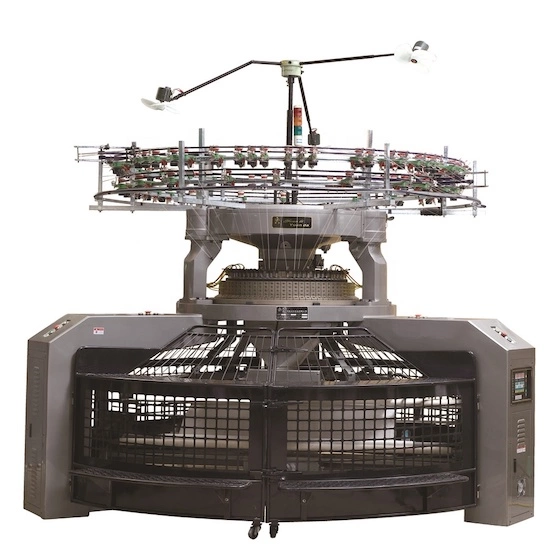

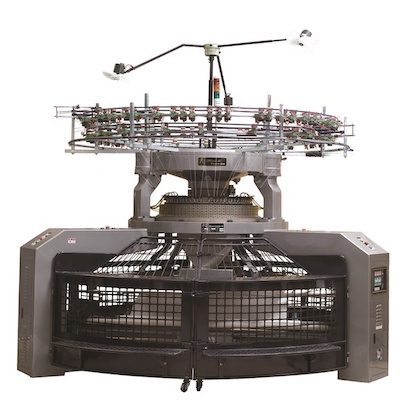

An open-width circular knitting machine is a type of textile machinery used in the production of knitted fabrics. It is designed to create single jersey and double jersey fabrics, with the open-width feature allowing for larger fabric widths. This circular knitting machine is equipped with multiple needles and cam systems, allowing for versatile knitting patterns and designs. The machine operates using a continuous loop of yarn, producing seamless fabrics. It is ideal for the production of clothing, accessories, and other textile goods. With its high efficiency and precision, the open-width circular knitting machine is an essential investment for textile manufacturers seeking to boost productivity and quality.

An open-width knitting machine includes a single jersey open-width knitting machine and a double jersey open-width knitting machine. The single jersey open-width knitting machine can manufacture fabric without wrinkles. The double jersey open-width knitting machine adopts a high-speed motor and a large-diameter cyliner. Unnecessary fabric loss can be reduced by the automatic cutting system. Cloth with different sizes can be process qutomatically by the cloth collecting stick.

An open-width knitting machine includes a single jersey open-width knitting machine and a double jersey open-width knitting machine. The single jersey open-width knitting machine can manufacture fabric without wrinkles. The double jersey open-width knitting machine adopts a high-speed motor and a large-diameter cyliner. Unnecessary fabric loss can be reduced by the automatic cutting system. Cloth with different sizes can be process qutomatically by the cloth collecting stick.

More information about the open width circular knitting machine

| Sizes | Gauges | No. of Feeders | Available Yarn Materials |

| 26 - 44 Inch | 12-40 Gauges for single jersey open-width knitting machine 16 -38 Gauges for double jersey open-width knitting machine |

78-132 Feeders(3 feeders/inch), 104-176 Feeders (4 feeders/inch) for single jersey open-width knitting machine 52-88 Feeders for double jersey open-width knitting machine |

Synthetic fiber, silk, cotton, artificial wool, mesh or elastic cloth. |

Equipment

| Items | Component | Description/Brand | |||||

| 1 | Machine structure | China mainland | |||||

| 2 | Cylinder | Japanese Steel Metel S45CL | |||||

| 3 | Cam Material | Japanese Steel Metel Grade SKD11 | |||||

| 4 | Vertical Yarn Feeder | Taiwan | |||||

| 5 | Cam Set up S/J | 2 Knit + 1 Miss + 1 Tuck | |||||

| 6 | Cam Set Up D/J | 2 Knit + 1 Miss + 1 Tuck | |||||

| 7 | Needle | Groz-Becker, Germany | |||||

| 8 | Sinker | Kernliebers, Germany | |||||

| 9 | Positive Feeders | China mainland | |||||

| 10 | Teeth Belt for positive feeder | Japan | |||||

| 11 | Lycra Feeders | China mainland | |||||

| 12 | Teeth Belt for lycra feeder | Japan | |||||

| 13 | Lycra Bottom Stop Motion | China mainland | |||||

| 14 | Oil Lubricator | Taiwan | |||||

| 15 | Inverter | Taiwan | |||||

| 16 | Motor | Taiwan | |||||

| 17 | Control Panel | Taiwan | |||||

| 18 | Aluminium Top Yarn Creel | Taiwan | |||||

| 19 | Quality adjustment Pully | Taiwan | |||||

| 20 | Aluminum Side Tube Creel | Taiwan | |||||

| 21 | Open width fabric take down system (open width only) | Taiwan | |||||

| 23 | Mechanical Take up system (D/J use only) | Taiwan | |||||

| 24 | Plaiter(S/J use only) | Taiwan | |||||

| 25 | Fabric Spreader to Control Shrinkage | Taiwan | |||||

| 26 | Needle detector | Taiwan | |||||

Showing 1–12 of 9 results

Open-width circular knitting machines made by Yuanda

Advanced Control System

Good quality

Good inter-convertibility

Fast deliver time

Open-width single jersey circular knitting machine

Definition

A single jersey open-width knitting machine is capable of processing many synthetic fibers easily for a lot of plating fabrics, urethane elastic fabric, double thread velvet, and elastic silk cotton. The fabric can be cut automatically by installing a special open width fabric taken down device, ensuring smooth fabric without any wrinkle.

Features

Easily adjusted size, density and thickness of the fabric

A long service life of the needles and equipment

Central Stitch Adjustment making accurate adjustment for density of fabric

No break in the center or on the surface of the fabric

Enhanced gearing systems providing easy operation, adjustment and smoothness

Having less waste for fabric and higher profits

Operating inch-by-inch and maintaining accuracy

Request a quote

A single jersey open-width knitting machine is capable of processing many synthetic fibers easily for a lot of plating fabrics, urethane elastic fabric, double thread velvet, and elastic silk cotton. The fabric can be cut automatically by installing a special open width fabric taken down device, ensuring smooth fabric without any wrinkle.

Features

Easily adjusted size, density and thickness of the fabric

A long service life of the needles and equipment

Central Stitch Adjustment making accurate adjustment for density of fabric

No break in the center or on the surface of the fabric

Enhanced gearing systems providing easy operation, adjustment and smoothness

Having less waste for fabric and higher profits

Operating inch-by-inch and maintaining accuracy

Open-width double jersey circular knitting machine

Features

Providing the function of safe shutdown

Uniform and stable knitting tightness to the fabric due to a roller speed adjustment device of the cloth-cutting machine

Automatically rolling up cloth of the cloth collecting stick for processing cloth with diverse sizes

Cylinder with a large diameter and motor with high speeds

Automatic cutting system providing unnecessary fabric loss

High productivity

Less cutting waste when further processing fabric

No crease in the center or on the surface of the fabric

Applicable Yarn Materials, including cotton, synthetic fiber, silk, artificial wool, mesh or elastic cloth.

Providing the function of safe shutdown

Uniform and stable knitting tightness to the fabric due to a roller speed adjustment device of the cloth-cutting machine

Automatically rolling up cloth of the cloth collecting stick for processing cloth with diverse sizes

Cylinder with a large diameter and motor with high speeds

Automatic cutting system providing unnecessary fabric loss

High productivity

Less cutting waste when further processing fabric

No crease in the center or on the surface of the fabric

Applicable Yarn Materials, including cotton, synthetic fiber, silk, artificial wool, mesh or elastic cloth.

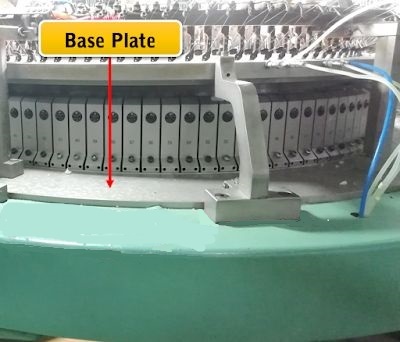

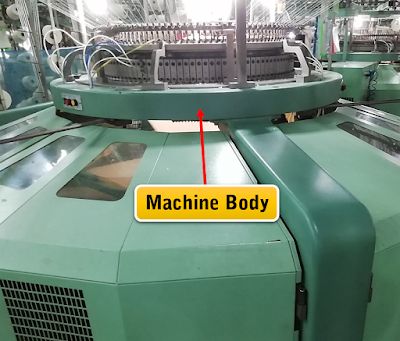

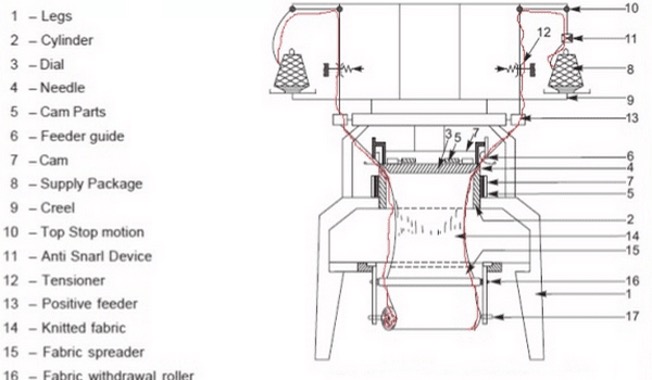

Parts of open width knitting machines

Circular knitting machines usually have parts such as cylinders, needles, feeders, cams, cam boxes, take up rollers, yarn tension

Cylinder

A cylinder is used to set all the needles, which is one of the essential parts of circular knitting machines.

Needle

A needle can knit the fabric, which is one of the main parts of circular knitting machines. A needle includes a bearded needle, a latch needle and a compound needle and a latch needle is the most used.

Latch needle

A latch needle consists of a latch, a curved hook, a tumbler which swings on a rivet under the hook, stem and butt, which is applied to raschel and crochet machines. It can be referred to as an automatic needle sometimes because a presser is not required. The pressure of a completed loop on the latch closes the hook as the latch rises on the shaft.

Positive feeder

A positive feeder is applied to stabilizing and adjusting the tension of the yarn feed. The self-cleaning tension ring is impressed on the wear-free yarn feed wheel and yarn infeed tensioner by the MPF L.

Lycra Feeder

The tension of the spandex feed is stabilized and adjusted by the lycra feeder.

Cam

A cam is a crucial part of the knitting machine, which transmits the force to the needle bar and makes it move in a regular manner. In the fields of textiles, light industry, and mechanical transmission, cams are often applied. Different complicated regular movements can be achieved by using cams with different contours and grooves.

Cam box

A cam box has the function of holding the cam based on the design of the fabric.

Creel

Creel is used to put the yarn cone where the yarn is transported to the machine through the pipe.

Auto Stopper

If the knitting machine malfunctions, the automatic stopper will automatically stop the knitting machine.

VDQ pulley

VDQ is the variable dia of the quality pulley, which has control of the quality of the fabric and is essential for keeping appropriate stitch length.

Sinker

A sinker is used to support the threads when forming the loop. The knitting sinker is one of the most essential components of circular knitting machines and has always played an important role in the knitting process of the fabric. Sinkers with good quality are the basis for knitting fabrics with good quality.

The cloth rolling machine

Different types of rolling cloth can be handled by the cloth rolling machine and can meet the various processing needs of businesses. In the field of processing garments, the cloth rolling machine is one of the most important machines. From production to completion, it is necessary to inspect and roll the fabric, and this is the time when a professional rolling machine is needed. After the power is on, the cloth rolling machine will start to roll the cloth automatically, which should be paid attention to.

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links