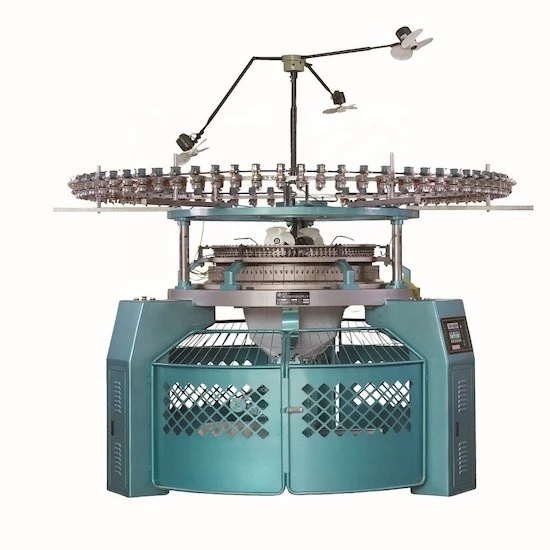

A single jersey circular knitting machine is a type of textile manufacturing equipment used to produce knitted fabrics with a single set of needles. It is designed to create seamless and stretchable fabrics and is commonly used in the production of T-shirts, athletic wear, and fashion apparel. The machine operates by continuously feeding yarn through a set of circular needles, which interlock the yarn to create loops and form the desired fabric. With the ability to knit at high speeds, this machine offers impressive efficiency and productivity. Additionally, it provides a range of stitch densities and patterns, making it a versatile tool for textile producers.

A single jersey circular knitting machine is used to manufacture vest, t-shirt, polo shirts, functional sportswear and underwear. It has a strong frame made of casting iron, so that the part will not deform, providing stabibilty and good operation. The key part can be replace to knit different fabrics, improving productivity.

A single jersey circular knitting machine is used to manufacture vest, t-shirt, polo shirts, functional sportswear and underwear. It has a strong frame made of casting iron, so that the part will not deform, providing stabibilty and good operation. The key part can be replace to knit different fabrics, improving productivity.

More information about the single jersey knitting machine

| Sizes | Gauges | No. of Feeders | Available Yarn Materials |

| 6-44 Inch | 14-44 Gauges | 18-132 Feeders (3 feeders/inch) | Pure cotton, chemical fiber, mixed fiber, silk, and artificial wool, etc. |

Equipment

| Items | Component | Description/Brand | |||||

| 1 | Machine structure | China mainland | |||||

| 2 | Cylinder | Japanese Steel Metel S45CL | |||||

| 3 | Cam Material | Japanese Steel Metel Grade SKD11 | |||||

| 4 | Vertical Yarn Feeder | Taiwan | |||||

| 5 | Cam Set up S/J | 2 Knit + 1 Miss + 1 Tuck | |||||

| 6 | Cam Set Up D/J | 2 Knit + 1 Miss + 1 Tuck | |||||

| 7 | Needle | Groz-Becker, Germany | |||||

| 8 | Sinker | Kernliebers, Germany | |||||

| 9 | Positive Feeders | China mainland | |||||

| 10 | Teeth Belt for positive feeder | Japan | |||||

| 11 | Lycra Feeders | China mainland | |||||

| 12 | Teeth Belt for lycra feeder | Japan | |||||

| 13 | Lycra Bottom Stop Motion | China mainland | |||||

| 14 | Oil Lubricator | Taiwan | |||||

| 15 | Inverter | Taiwan | |||||

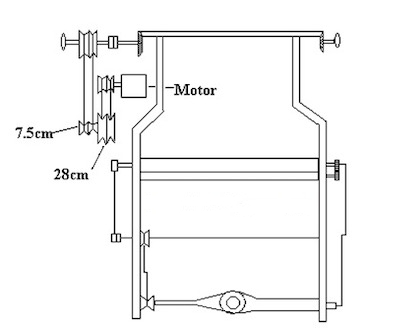

| 16 | Motor | Taiwan | |||||

| 17 | Control Panel | Taiwan | |||||

| 18 | Aluminium Top Yarn Creel | Taiwan | |||||

| 19 | Quality adjustment Pully | Taiwan | |||||

| 20 | Aluminum Side Tube Creel | Taiwan | |||||

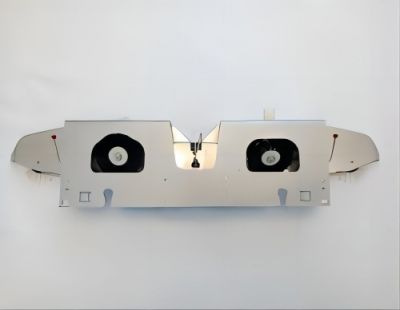

| 21 | Open width fabric take down system (open width only) | Taiwan | |||||

| 23 | Mechanical Take up system (D/J use only) | Taiwan | |||||

| 24 | Plaiter(S/J use only) | Taiwan | |||||

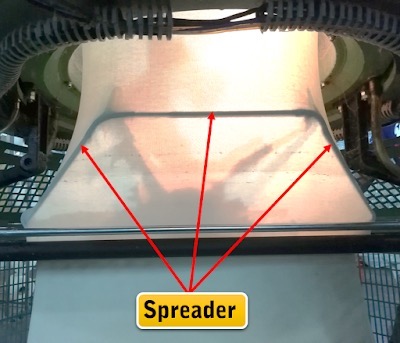

| 25 | Fabric Spreader to Control Shrinkage | Taiwan | |||||

| 26 | Needle detector | Taiwan | |||||

Showing 1–12 of 26 results

Single Jersey Knitting Machines

Definition

A single jersey knitting circular machine is a kind of machine commonly used in the production of knitted fabrics, such as pure cotton, chemical fiber, mixed fiber, silk, and artificial wool. A single jersey machine has only one cylinder on which a set of needles and sinkers are placed on. The sinker ring and cylinder revolve around the motionless knitting cam system. Fixed yarn feeders are located at regular intervals around the cylinder’s circumference.

Descriptions

The single jersey circular knitting machine is electrically driven and possesses 18 to 132 feeders (3 feeders/inch) or 24 to 176 feeders (4 feeders/inch). The diameter of the cylinder is 6 to 44 inches. The single jersey circular knitting machine can only manufacture single jersey fabrics.

Request a quote

A single jersey knitting circular machine is a kind of machine commonly used in the production of knitted fabrics, such as pure cotton, chemical fiber, mixed fiber, silk, and artificial wool. A single jersey machine has only one cylinder on which a set of needles and sinkers are placed on. The sinker ring and cylinder revolve around the motionless knitting cam system. Fixed yarn feeders are located at regular intervals around the cylinder’s circumference.

Descriptions

The single jersey circular knitting machine is electrically driven and possesses 18 to 132 feeders (3 feeders/inch) or 24 to 176 feeders (4 feeders/inch). The diameter of the cylinder is 6 to 44 inches. The single jersey circular knitting machine can only manufacture single jersey fabrics.

Features of single jersey knitting machines

Equipped with miss cams, knit cams and tuck cams, and using the 4 track cams seal design.

High-precision central lifting systems and falling systems can be used for easy and quick fabric weight adjustment.

Special feeding yarn carriers for a more proficient selection of Lycra.

Ergonomic design with an additional intermediate feeding yarn transfer ring, convenient for operators to monitor and carry yarn, and the machine does not touch the operator.

Freer and more stable yarn feeding system can achieve the purpose of high-speed knitting.

The single jersey circular knitting machine has a multi-purpose function and can be easily converted into a 3-thread-fleece, terry machine and other machines by replacing the core parts.

The central adjustment system is adopted to adjust fabrics easily and cylinders with different gauges are used, knitting many kinds of single jersey fabrics.

The single jersey knitting machine has high productivity and good inter-convertibility.

Conversion kits allow for single jersey, terry and fleece machine changes.

High-precision central lifting systems and falling systems can be used for easy and quick fabric weight adjustment.

Special feeding yarn carriers for a more proficient selection of Lycra.

Ergonomic design with an additional intermediate feeding yarn transfer ring, convenient for operators to monitor and carry yarn, and the machine does not touch the operator.

Freer and more stable yarn feeding system can achieve the purpose of high-speed knitting.

The single jersey circular knitting machine has a multi-purpose function and can be easily converted into a 3-thread-fleece, terry machine and other machines by replacing the core parts.

The central adjustment system is adopted to adjust fabrics easily and cylinders with different gauges are used, knitting many kinds of single jersey fabrics.

The single jersey knitting machine has high productivity and good inter-convertibility.

Conversion kits allow for single jersey, terry and fleece machine changes.

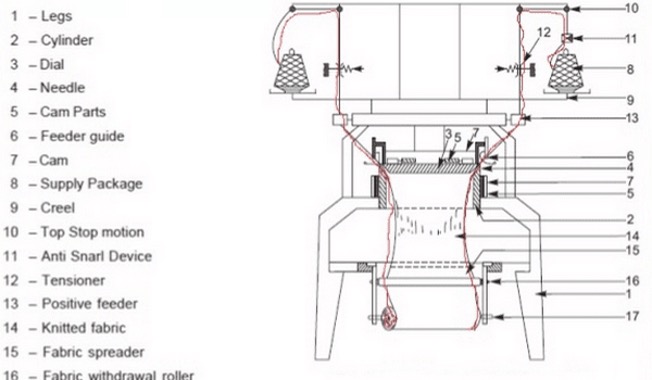

Parts of single jersey circular knitting machines

Circular knitting machines usually have parts such as cylinders, cylinder gears, needles, feeders, sinkers, sinker plates, cams, cam boxes, take up rollers, auto motion stopper, high stand, handle and clatch, take-down roller, crank shaft, machine pulley, etc.

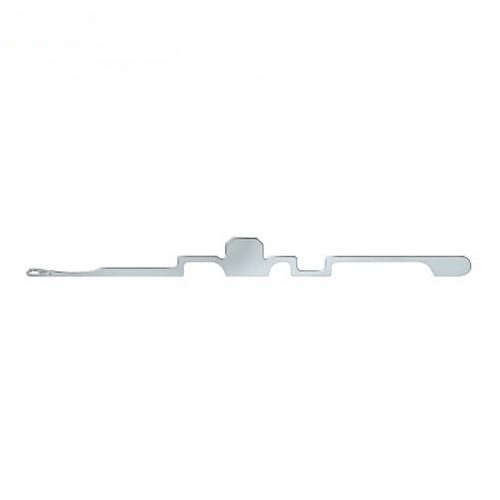

Latch needle

A latch need is applied to manufacturing loops. It is a fine steel needle applied to knitting, with a butt at one end and a short hook enclosed by a latch at the other end.

Advantages of latch needles

Making the fabric have good quality

High speed effectively increasing productivity

Energy savings and reducing manufacturing costs.

High speed effectively increasing productivity

Energy savings and reducing manufacturing costs.

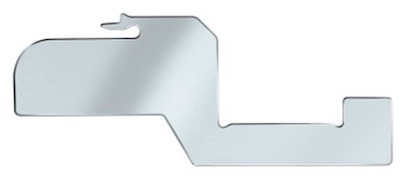

Sinker

A sinker is applied to keep the new loop and release the old loop. The knitting sinker is one of the most essential components of circular knitting machines. Sinkers with good quality can provide knitting fabrics with good quality.

Auto motion stopper

When the yarn breaks, an auto motion stopper is applied to automatically stopping the machine by the clatch.

High stand

The high stand is the auxiliary hand that pulls the yarn away from the bobbin.

Take-down roller

A take-down roller is applied to removing the fabric from the cylinder with the appropriate tension.

Crank shaft

A crank shaft is applied to shifting the movement from the take-down roller to crank roller.

Machine pulley

A machine pulley is applied to accumulating mechanical power by a V-belt and transmiting the movement in the bevel gear.

Cylinder

A cylinder is used to set all the needles, which is one of the essential parts of circular knitting machines.

Positive feeders

A positive feeder is applied to stabilizing and adjusting the tension of the yarn feed. The self-cleaning tension ring is impressed on the wear-free yarn feed wheel and yarn infeed tensioner by the MPF L.

Features of positive feeders

Good corrosion and wear resistance of the yarn storage wheel

Locked front and back probe rods facilitating idling or adjusting

Adjustable magnetic clamping plates, spring clamping plates and magnetic clamping plates

Light weight of the probe decreasing tenson of the yarn feed.

Easy maintenance for positive feeders due to the bright finish on the surface.

Locked front and back probe rods facilitating idling or adjusting

Adjustable magnetic clamping plates, spring clamping plates and magnetic clamping plates

Light weight of the probe decreasing tenson of the yarn feed.

Easy maintenance for positive feeders due to the bright finish on the surface.

Lycra Feeder

The tension of the spandex feed is stabilized and adjusted by the lycra feeder.

Features of Lycra Feeders

A mechanical lever is used for the yarn breaking automatic stop device. According to the spandex’s tension, the counterbalance can be changed. The light path will be blocked and the yarn breaking stop signal triggered after the yarn breaks.

High-precision yarn feeding can be obtained because of all-metal shells and integrated wire feeding rollers, so that the quality of the fabric can be good.

The position of breakage of the yarn can be found easily due to the integrated LED indicator light, resulting in high work efficiency.

The breakage of the yarn can be analyzed by the optical technology and a reminder will be sent.

High-precision yarn feeding can be obtained because of all-metal shells and integrated wire feeding rollers, so that the quality of the fabric can be good.

The position of breakage of the yarn can be found easily due to the integrated LED indicator light, resulting in high work efficiency.

The breakage of the yarn can be analyzed by the optical technology and a reminder will be sent.

Cam

A cam is applied to lifting the needle and is a crucial part of the knitting machine, which transmits the force to the needle bar and makes it move in a regular manner. Different complicated regular movements can be achieved by using cams with different contours and grooves.

The cloth rolling machine

Different types of rolling cloth can be handled by the cloth rolling machine and can meet the various processing needs of businesses. The cloth rolling machine has multi-step changing speeds and an intensive average of changing speed with no speed repetition. There is a large pack-up cloth extent, which is easy to use. The wet lubricant was adopted for the machine's gear case, which is easy to maintain and not susceptible to wear. The size and tightness of the cloth can be fixed by the machine, and the needle's service life can be longer. By using this machine, the cloth shows no difference in starting and ending stripe distance and yard weight.

Fabric

Single jersey fabric

Single jersey fabric is the most used t-shirt fabric in textile. It has a two different sides and is popular due to its warmth, flexibility, elasticity and comfortability.

Request a quote

About Us

We have been committed to manufacturing all types of circular knitting machines with great quality and reasonable price for a long time. Our professional team is highly specialized and problem-solving oriented. We put the most effort into meeting your knitting demands, achieving a win-win situation.

Categories

Useful Links