Chức năng, nguyên tắc và quy trình làm việc của máy dệt kim tròn

Nov 11, 2023

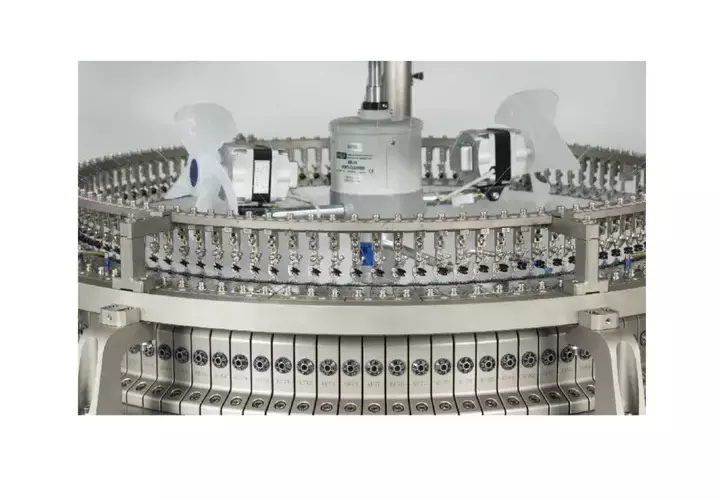

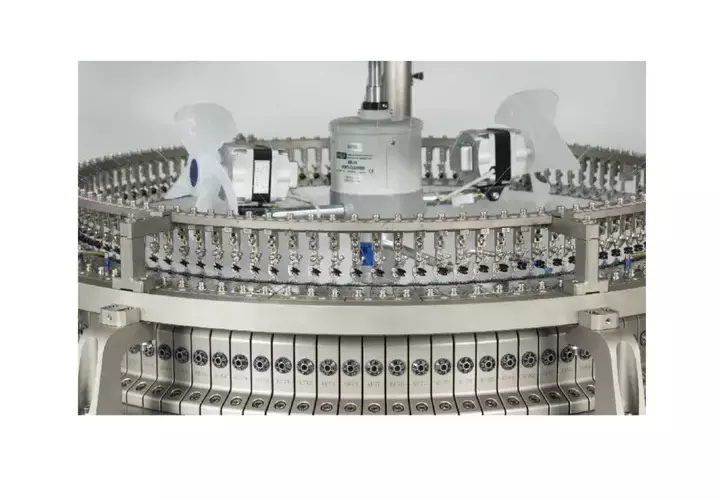

In the realm of textile machinery, the circular knitting machine, a commonly chosen industrial textile device, holds a significant presence in manufacturing.The primary function of a circular knitting machine is to produce knitted fabric, utilized for various applications such as everyday undergarments, activewear, sweatshirts, T-shirts, and other semi-finished textile products. After production, the fabrics typically undergo dyeing and further processing before being transformed into clothing.

Principles of Operation:

The circular knitting machine operates based on the principle of power transmission through a series of mechanisms. The motor drives a small gear through a belt and pulley system, which, in turn, propels a large disc gear fixed with needle cylinders. The upper part of the frame is secured with the large disc gear, while the lower part rests on a fixed cam gear. As the large disc gear rotates, it synchronously rotates the entire take-down mechanism and needle cylinders. Simultaneously, the cam gear engaged with gear 8, after passing through a variable speed gearbox, drives the rotation of a transverse axis. Connected by a chain, the transverse axis drives the take-up roller to initiate the fabric-pulling process. The other side of the transverse axis, connected by a chain, propels the active pulley wheel, driving the coiling roller in synchronization. Through belt transmission from the active pulley wheel, the passive pulley wheel is driven, in turn powering the coiling roller for fabric winding.

Applications:

Utilizing needle selection mechanisms to deploy needles according to a predetermined program for the production of jacquard knitted fabrics.

Employing a brushing mechanism to feed loose fibers into the knitting needles, creating long-pile plush knitted fabrics.

Incorporating warp and weft lining devices to produce warp-knitted and weft-knitted fabrics.

Có hơn 350 loại máy dệt kim tròn, với sự phát triển của các loại sợi hóa học mới và công nghệ xử lý sau, các đặc tính như độ cứng, chống nhăn và độ bền của vải đã được cải thiện. Việc áp dụng các kỹ thuật hoàn thiện như nhồi nhét, cắt, chải, dập nổi và xếp nếp đã mở rộng sự đa dạng của các sản phẩm dệt kim.

Working Process of the Circular Knitting Machine:

Sự hình thành của vòng:

Sợi được tạo thành một cuộn dây thông qua sợi thẳng đứng và kết nối ngang, cuối cùng tạo thành một loại vải dệt kim. Hình thành cuộn dây là quá trình cơ bản của dệt kim.

Looping Stages:

Withdrawal of Loops: Move just-formed loops (termed "day loops") from the needle hook to the needle bar.

Yarn Insertion: Feed yarn onto the knitting needle.

Bending Yarn: Bend the yarn into the shape of loops, transferring newly inserted or recently bent yarn to the needle hook.

Đóng: niêm phong miệng kim.

Looping: Form a closed and predetermined-sized loop.

Drawing: Pull the newly formed loop away from the looping area.

Loop Connection:

Looping Together: Bring a new yarn or loop into contact with the day loop inside and outside the needle hook.

Loop Removal: Remove the day loop from the needle hook, placing it onto the new loop.

Hình thành cuộn dây: Hình thành sợi thành một cuộn dây mới có kích thước cụ thể đóng.

Traction: Pull the new loop away from the looping area. This loop becomes the old loop in the next looping cycle.

The looping process can be categorized into knitting and braiding methods. In knitting method looping, the looping stages proceed in the aforementioned order. In braiding method looping, yarn bending starts with loop removal and occurs simultaneously with looping stages. In some knitting machines, individual knitting needles sequentially complete the looping process, while in others, multiple knitting needles perform the looping process simultaneously.

In summary, the circular knitting machine is a versatile and essential tool in textile manufacturing, playing a crucial role in the creation of various knitted fabrics with diverse applications. Understanding its functions and principles is key to optimizing its performance and expanding the range of knitted products.

Principles of Operation:

The circular knitting machine operates based on the principle of power transmission through a series of mechanisms. The motor drives a small gear through a belt and pulley system, which, in turn, propels a large disc gear fixed with needle cylinders. The upper part of the frame is secured with the large disc gear, while the lower part rests on a fixed cam gear. As the large disc gear rotates, it synchronously rotates the entire take-down mechanism and needle cylinders. Simultaneously, the cam gear engaged with gear 8, after passing through a variable speed gearbox, drives the rotation of a transverse axis. Connected by a chain, the transverse axis drives the take-up roller to initiate the fabric-pulling process. The other side of the transverse axis, connected by a chain, propels the active pulley wheel, driving the coiling roller in synchronization. Through belt transmission from the active pulley wheel, the passive pulley wheel is driven, in turn powering the coiling roller for fabric winding.

Applications:

Utilizing needle selection mechanisms to deploy needles according to a predetermined program for the production of jacquard knitted fabrics.

Employing a brushing mechanism to feed loose fibers into the knitting needles, creating long-pile plush knitted fabrics.

Incorporating warp and weft lining devices to produce warp-knitted and weft-knitted fabrics.

Có hơn 350 loại máy dệt kim tròn, với sự phát triển của các loại sợi hóa học mới và công nghệ xử lý sau, các đặc tính như độ cứng, chống nhăn và độ bền của vải đã được cải thiện. Việc áp dụng các kỹ thuật hoàn thiện như nhồi nhét, cắt, chải, dập nổi và xếp nếp đã mở rộng sự đa dạng của các sản phẩm dệt kim.

Working Process of the Circular Knitting Machine:

Sự hình thành của vòng:

Sợi được tạo thành một cuộn dây thông qua sợi thẳng đứng và kết nối ngang, cuối cùng tạo thành một loại vải dệt kim. Hình thành cuộn dây là quá trình cơ bản của dệt kim.

Looping Stages:

Withdrawal of Loops: Move just-formed loops (termed "day loops") from the needle hook to the needle bar.

Yarn Insertion: Feed yarn onto the knitting needle.

Bending Yarn: Bend the yarn into the shape of loops, transferring newly inserted or recently bent yarn to the needle hook.

Đóng: niêm phong miệng kim.

Looping: Form a closed and predetermined-sized loop.

Drawing: Pull the newly formed loop away from the looping area.

Loop Connection:

Looping Together: Bring a new yarn or loop into contact with the day loop inside and outside the needle hook.

Loop Removal: Remove the day loop from the needle hook, placing it onto the new loop.

Hình thành cuộn dây: Hình thành sợi thành một cuộn dây mới có kích thước cụ thể đóng.

Traction: Pull the new loop away from the looping area. This loop becomes the old loop in the next looping cycle.

The looping process can be categorized into knitting and braiding methods. In knitting method looping, the looping stages proceed in the aforementioned order. In braiding method looping, yarn bending starts with loop removal and occurs simultaneously with looping stages. In some knitting machines, individual knitting needles sequentially complete the looping process, while in others, multiple knitting needles perform the looping process simultaneously.

In summary, the circular knitting machine is a versatile and essential tool in textile manufacturing, playing a crucial role in the creation of various knitted fabrics with diverse applications. Understanding its functions and principles is key to optimizing its performance and expanding the range of knitted products.

next: Phân loại và tổng quan về máy dệt kim tròn

previous: Nguyên nhân và biện pháp đối phó với máy dệt kim tròn

Giới thiệu về chúng tôi

categories

Useful Links