Làm thế nào để chọn máy dệt kim tròn chất lượng cao

Nov 11, 2023

Circular knitting machines belong to precision machinery, and the coordination of each system is crucial. The shortcomings of each system will become the performance limit of the machine. This is why, despite the seemingly simple production of circular knitting machines, there are only a few brands that excel in the market.

Many customers fall into a misconception when selecting circular knitting machines, focusing only on visible brand configurations such as yarn storage and needles, often overlooking the most critical aspects of the machine. Therefore, sometimes purchased machines are like small shrimps equipped with large crab claws – they may look luxurious, but the investment might not be practical.

Today, we will break down and discuss in detail what constitutes a balanced and stable machine, covering aspects such as the support structure, knitting system, cleaning system, transmission mechanism, lubrication system, yarn feeding system, and pulling mechanism.

Support Structure (Frame):

The support structure is like the skeleton of the human body; a machine with porous and loose castings will lack stability. Vibrations, even slight ones, during high-speed operation can affect the final fabric appearance. Natural aging is crucial for castings, involving exposing them to outdoor elements to release residual stresses and achieve stable precision.

Knitting System:

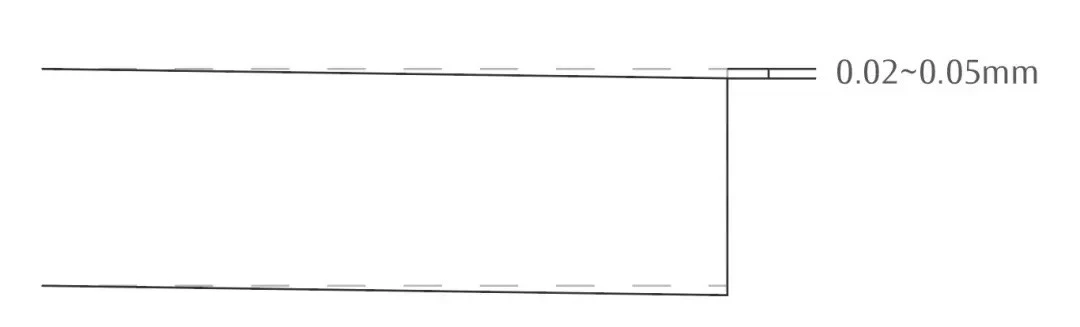

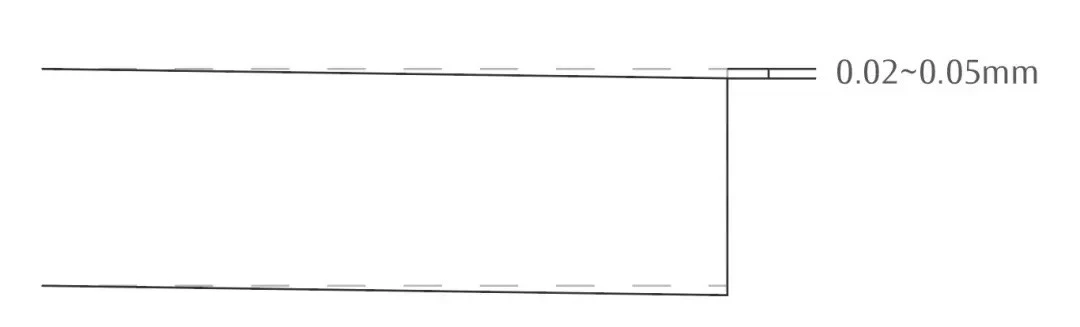

Needle Cylinder: The material of the needle cylinder is crucial, as it undergoes repeated friction from the knitting needles. Choosing a high-quality material, such as quick-cutting alloy steel treated with heat, ensures durability.

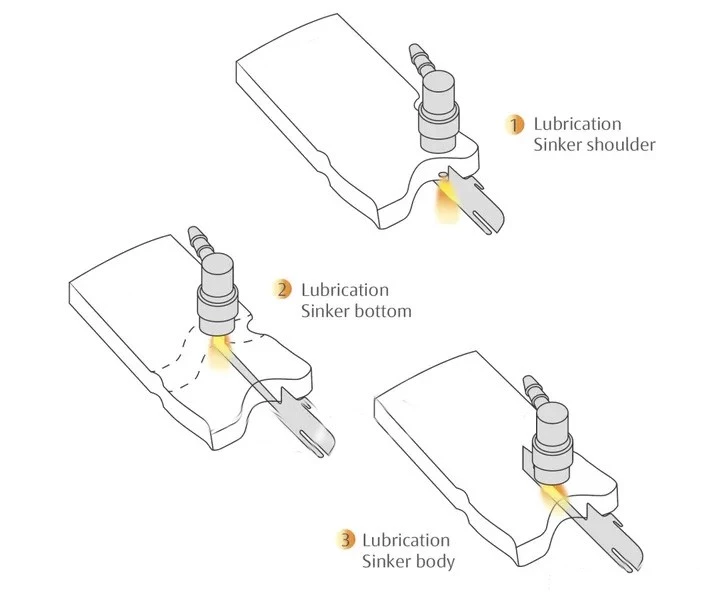

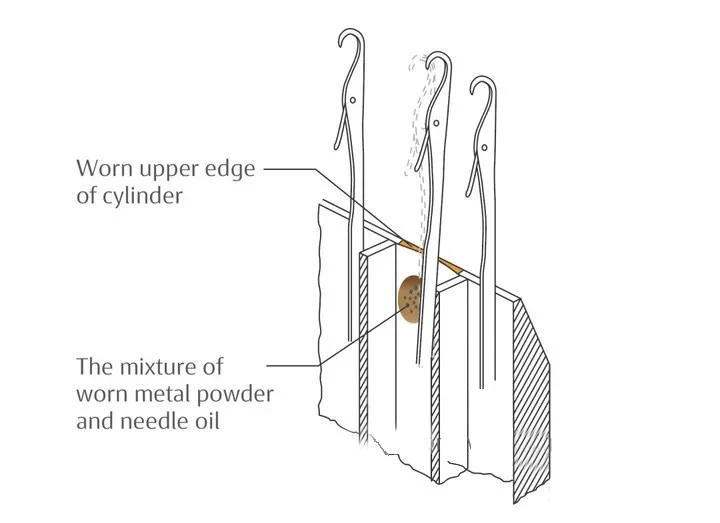

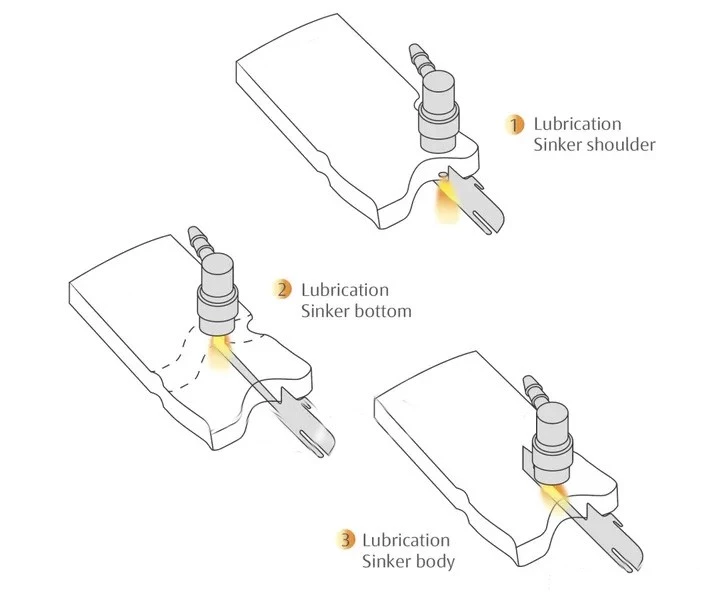

Lubrication System:

Bôi trơn đầy đủ là rất quan trọng đối với tuổi thọ của chìm và kim, giúp giảm tần suất bảo trì và chi phí vận hành. Việc bôi trơn đúng vai, gót chân và cơ thể của quả bóng chìm là rất quan trọng. Vị trí của vòi phun dầu là chìa khóa, và không khí được phun lên móc kim và lưỡi kim-hỗn hợp dầu đảm bảo sự sạch sẽ và linh hoạt.

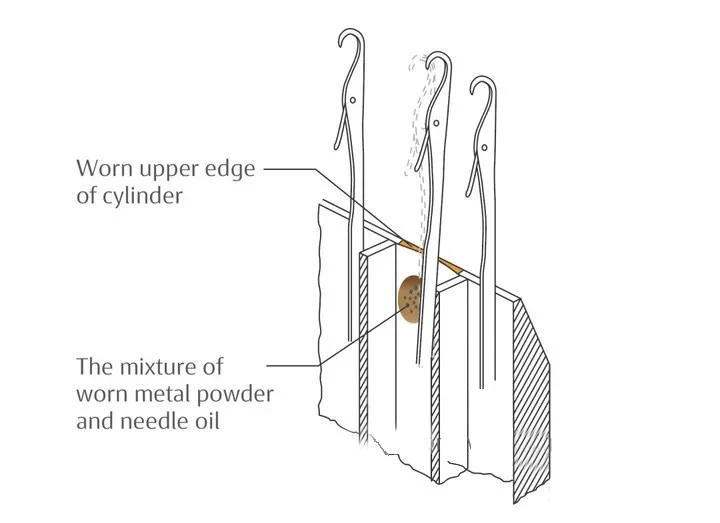

Cleaning System:

The cleaning system helps prolong cleaning intervals, reduce maintenance efforts, and minimize downtime, enhancing overall production efficiency. Optimal fan design, such as reverse centrifugal dust removal, ensures even and extended contact with dust removal points.

Yarn Feeding System:

While yarn storage units are commonly considered, the yarn rack is often overlooked. Sturdy materials, like thick square steel and solid supports, contribute to a more stable yarn feeding system, preventing jitter during high-speed operation and preserving fabric appearance.

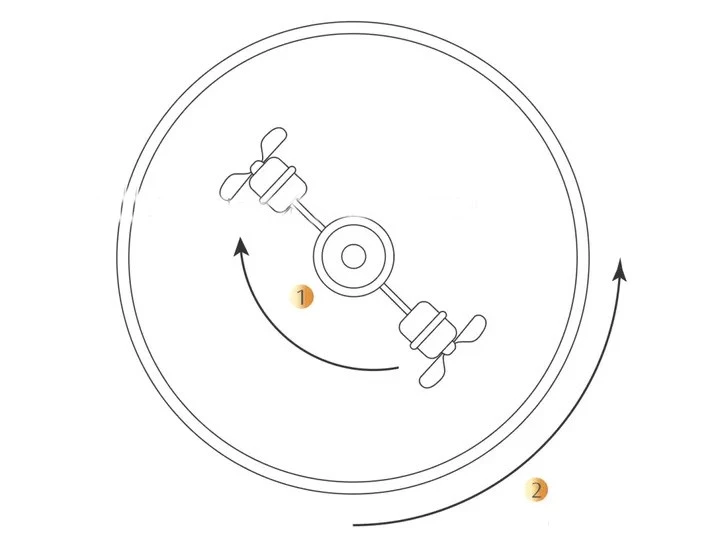

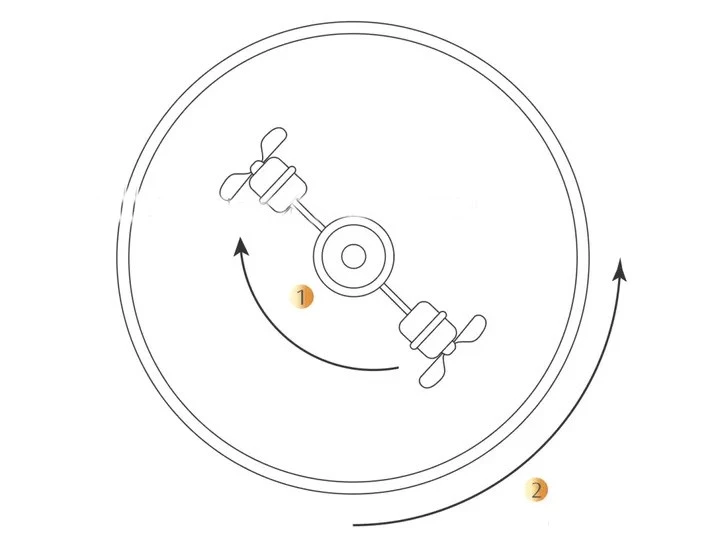

Transmission Mechanism:

Choosing stable and reliable brands for the motor and frequency converter is crucial. Synchronous belts with stable transmission ratios contribute to reliable performance. Bearings, though often overlooked, play a crucial role in various systems and warrant detailed inquiry into the manufacturer's choice.

Pulling Mechanism:

Hấp thụ sốc: Hệ thống hấp thụ sốc tốt có thể kéo dài tuổi thọ của hộp số con lăn vải và giảm mài mòn của bánh răng tấm lớn ngoài số lượng nút và sự đồng nhất và căng thẳng của con lăn vải.

Installation Precision: Ensuring that the machine is assembled strictly according to installation precision requirements is crucial. Precision reflects the material grade and installation level.

Meeting these basic requirements represents the foundation of machine precision and quality. Another crucial point in choosing a manufacturer is their research and development (R&D) capabilities, especially when unique fabric structures and appearances are required. R&D capabilities determine how the machine's performance can be maximized, considering factors such as upper and lower plate cam curves, sinker throat depth, and coordination of timing, needle pressure, and tension, among others, for optimizing comprehensive performance.

In summary, a successful circular knitting machine requires attention to the fundamental aspects mentioned above and the manufacturer's research and development capabilities for achieving optimal performance in various fabric applications.

Many customers fall into a misconception when selecting circular knitting machines, focusing only on visible brand configurations such as yarn storage and needles, often overlooking the most critical aspects of the machine. Therefore, sometimes purchased machines are like small shrimps equipped with large crab claws – they may look luxurious, but the investment might not be practical.

Today, we will break down and discuss in detail what constitutes a balanced and stable machine, covering aspects such as the support structure, knitting system, cleaning system, transmission mechanism, lubrication system, yarn feeding system, and pulling mechanism.

Support Structure (Frame):

The support structure is like the skeleton of the human body; a machine with porous and loose castings will lack stability. Vibrations, even slight ones, during high-speed operation can affect the final fabric appearance. Natural aging is crucial for castings, involving exposing them to outdoor elements to release residual stresses and achieve stable precision.

Knitting System:

Needle Cylinder: The material of the needle cylinder is crucial, as it undergoes repeated friction from the knitting needles. Choosing a high-quality material, such as quick-cutting alloy steel treated with heat, ensures durability.

Lubrication System:

Bôi trơn đầy đủ là rất quan trọng đối với tuổi thọ của chìm và kim, giúp giảm tần suất bảo trì và chi phí vận hành. Việc bôi trơn đúng vai, gót chân và cơ thể của quả bóng chìm là rất quan trọng. Vị trí của vòi phun dầu là chìa khóa, và không khí được phun lên móc kim và lưỡi kim-hỗn hợp dầu đảm bảo sự sạch sẽ và linh hoạt.

Cleaning System:

The cleaning system helps prolong cleaning intervals, reduce maintenance efforts, and minimize downtime, enhancing overall production efficiency. Optimal fan design, such as reverse centrifugal dust removal, ensures even and extended contact with dust removal points.

Yarn Feeding System:

While yarn storage units are commonly considered, the yarn rack is often overlooked. Sturdy materials, like thick square steel and solid supports, contribute to a more stable yarn feeding system, preventing jitter during high-speed operation and preserving fabric appearance.

Transmission Mechanism:

Choosing stable and reliable brands for the motor and frequency converter is crucial. Synchronous belts with stable transmission ratios contribute to reliable performance. Bearings, though often overlooked, play a crucial role in various systems and warrant detailed inquiry into the manufacturer's choice.

Pulling Mechanism:

Hấp thụ sốc: Hệ thống hấp thụ sốc tốt có thể kéo dài tuổi thọ của hộp số con lăn vải và giảm mài mòn của bánh răng tấm lớn ngoài số lượng nút và sự đồng nhất và căng thẳng của con lăn vải.

Installation Precision: Ensuring that the machine is assembled strictly according to installation precision requirements is crucial. Precision reflects the material grade and installation level.

Meeting these basic requirements represents the foundation of machine precision and quality. Another crucial point in choosing a manufacturer is their research and development (R&D) capabilities, especially when unique fabric structures and appearances are required. R&D capabilities determine how the machine's performance can be maximized, considering factors such as upper and lower plate cam curves, sinker throat depth, and coordination of timing, needle pressure, and tension, among others, for optimizing comprehensive performance.

In summary, a successful circular knitting machine requires attention to the fundamental aspects mentioned above and the manufacturer's research and development capabilities for achieving optimal performance in various fabric applications.

next: Nguyên nhân và loại bỏ dấu vết ngừng hoạt động của máy dệt kim tròn

previous: Nguyên nhân phổ biến gây hư hỏng vải trong quá trình gỡ lỗi máy dệt kim tròn

Giới thiệu về chúng tôi

categories

Useful Links