Bảo trì máy dệt kim tròn

Nov 11, 2023

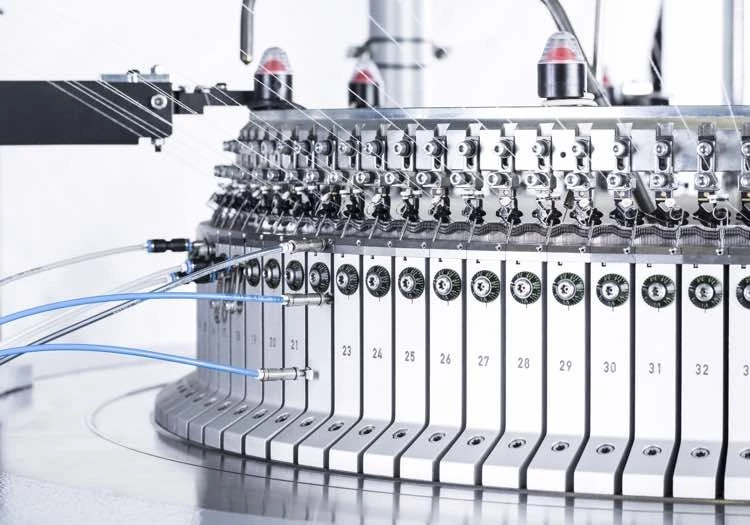

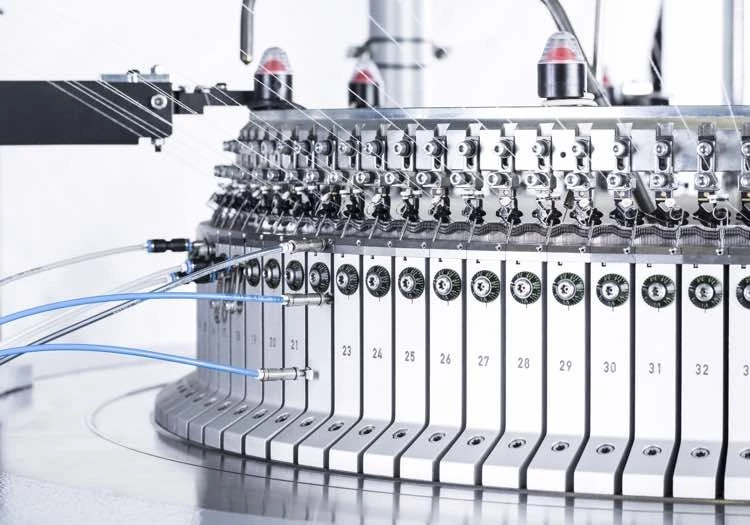

Firstly, conduct a comprehensive inspection of the circular knitting machine according to the manufacturer's technical documentation to ensure the completeness and integrity of various components. This includes the yarn rack, yarn accumulator, yarn breakage device, cam safety guard, spandex preparation, testing instruments (cover height gauge, alignment gauge), electrical components, and more. Verify the completeness of random accessories, such as triangles, sinkers, knitting needles, and other attachments, as specified in the contract or relevant documents.

Proceed with a trial run, a crucial step in installing and debugging the circular knitting machine. Run the machine for at least one day, with a focus on inspecting fabric styles and identifying any defects. During operation, check for slight vibrations in the sinker bed, yarn breaks, and probe sensor flexibility.

Working Environment Requirements for Circular Knitting Machines:

Due to the generation of airborne fibers during the knitting process, maintain a well-ventilated workshop. Control the workshop temperature, especially in winter to prevent resistance during machine operation and in summer to ensure the normal functioning of the frequency converter. Typically, control the temperature between 28-30 degrees Celsius with a relative humidity of 65-75 for optimal machine operation. Deviations in humidity can lead to issues such as stiff yarn, small needle holes, and rusting of needles and equipment.

Preservation and Maintenance Methods for Circular Knitting Machines:

Regularly clean cotton lint and fluff from machine components and the umbrella take-up device to ensure cleanliness.

During shift changes, inspect the positive yarn feeding device to prevent yarn feeder blockage, ensuring smooth rotation and avoiding defects in the fabric.

Thực hiện kiểm tra thường xuyên thiết bị dừng tự động và thiết bị bảo vệ bánh răng để giải quyết bất kỳ tình huống bất thường nào kịp thời.

During shift changes or routine inspections, check the oil circuits to ensure smooth lubrication throughout the machine.

Weekly Maintenance for Circular Knitting Machines:

Clean the yarn speed control disc to remove accumulated debris.

Check the belt tension of the transmission mechanism and ensure smooth operation.

Conduct a detailed inspection of the tension in the traction winding mechanism.

Monthly Maintenance for Circular Knitting Machines:

Remove upper and lower sinker beds, clearing accumulated lint from tracks and needle grooves.

Inspect the dust removal fan's airflow direction and clean dust from the fan.

Clean all electrical accessory components and verify their performance, including the auto-stop system and safety detection system.

Biannual Maintenance for Circular Knitting Machines:

Thoroughly clean and inspect all knitting needles and sinkers, replacing any damaged components.

Check the oil circuit for blockages, clean the oiling device, and adjust the misting quantity.

Clean and inspect the positive yarn feeding mechanism for flexibility.

Perform cleaning and maintenance on the electrical system.

Check the waste oil collection circuit for smooth operation.

Maintenance and care of the knitting mechanism are of utmost importance, directly influencing the fabric's style and quality. Pay special attention to:

Ensure smooth yarn passage and check yarn tension for adherence to process requirements. Inspect magnetic rings for damage and address wear issues in the path components.

Verify proper fabric tension, preventing excessive impressions on the fabric edges, especially with fabrics containing spandex.

Check for any loosening in the yarn guide position and adjust according to the horizontal/vertical angle relationship.

Inspect the fixation bolts of triangles/yarn guides to prevent loosening.

Các nhiệm vụ này được ưu tiên để tăng cường bảo trì và bảo dưỡng tổng thể máy dệt kim hình tròn, nhấn mạnh tầm quan trọng của việc quản lý thiết bị tỉ mỉ trong xưởng.

Proceed with a trial run, a crucial step in installing and debugging the circular knitting machine. Run the machine for at least one day, with a focus on inspecting fabric styles and identifying any defects. During operation, check for slight vibrations in the sinker bed, yarn breaks, and probe sensor flexibility.

Working Environment Requirements for Circular Knitting Machines:

Due to the generation of airborne fibers during the knitting process, maintain a well-ventilated workshop. Control the workshop temperature, especially in winter to prevent resistance during machine operation and in summer to ensure the normal functioning of the frequency converter. Typically, control the temperature between 28-30 degrees Celsius with a relative humidity of 65-75 for optimal machine operation. Deviations in humidity can lead to issues such as stiff yarn, small needle holes, and rusting of needles and equipment.

Preservation and Maintenance Methods for Circular Knitting Machines:

Regularly clean cotton lint and fluff from machine components and the umbrella take-up device to ensure cleanliness.

During shift changes, inspect the positive yarn feeding device to prevent yarn feeder blockage, ensuring smooth rotation and avoiding defects in the fabric.

Thực hiện kiểm tra thường xuyên thiết bị dừng tự động và thiết bị bảo vệ bánh răng để giải quyết bất kỳ tình huống bất thường nào kịp thời.

During shift changes or routine inspections, check the oil circuits to ensure smooth lubrication throughout the machine.

Weekly Maintenance for Circular Knitting Machines:

Clean the yarn speed control disc to remove accumulated debris.

Check the belt tension of the transmission mechanism and ensure smooth operation.

Conduct a detailed inspection of the tension in the traction winding mechanism.

Monthly Maintenance for Circular Knitting Machines:

Remove upper and lower sinker beds, clearing accumulated lint from tracks and needle grooves.

Inspect the dust removal fan's airflow direction and clean dust from the fan.

Clean all electrical accessory components and verify their performance, including the auto-stop system and safety detection system.

Biannual Maintenance for Circular Knitting Machines:

Thoroughly clean and inspect all knitting needles and sinkers, replacing any damaged components.

Check the oil circuit for blockages, clean the oiling device, and adjust the misting quantity.

Clean and inspect the positive yarn feeding mechanism for flexibility.

Perform cleaning and maintenance on the electrical system.

Check the waste oil collection circuit for smooth operation.

Maintenance and care of the knitting mechanism are of utmost importance, directly influencing the fabric's style and quality. Pay special attention to:

Ensure smooth yarn passage and check yarn tension for adherence to process requirements. Inspect magnetic rings for damage and address wear issues in the path components.

Verify proper fabric tension, preventing excessive impressions on the fabric edges, especially with fabrics containing spandex.

Check for any loosening in the yarn guide position and adjust according to the horizontal/vertical angle relationship.

Inspect the fixation bolts of triangles/yarn guides to prevent loosening.

Các nhiệm vụ này được ưu tiên để tăng cường bảo trì và bảo dưỡng tổng thể máy dệt kim hình tròn, nhấn mạnh tầm quan trọng của việc quản lý thiết bị tỉ mỉ trong xưởng.

next: Nguyên nhân và biện pháp đối phó với máy dệt kim tròn

previous: Cấu trúc cung cấp sợi của máy dệt kim tròn

Giới thiệu về chúng tôi

categories

Useful Links